Synthesis of Liquid Tall Oil Asphalt Amide Resin and Evaluation of Its Filtration Control Performance

-

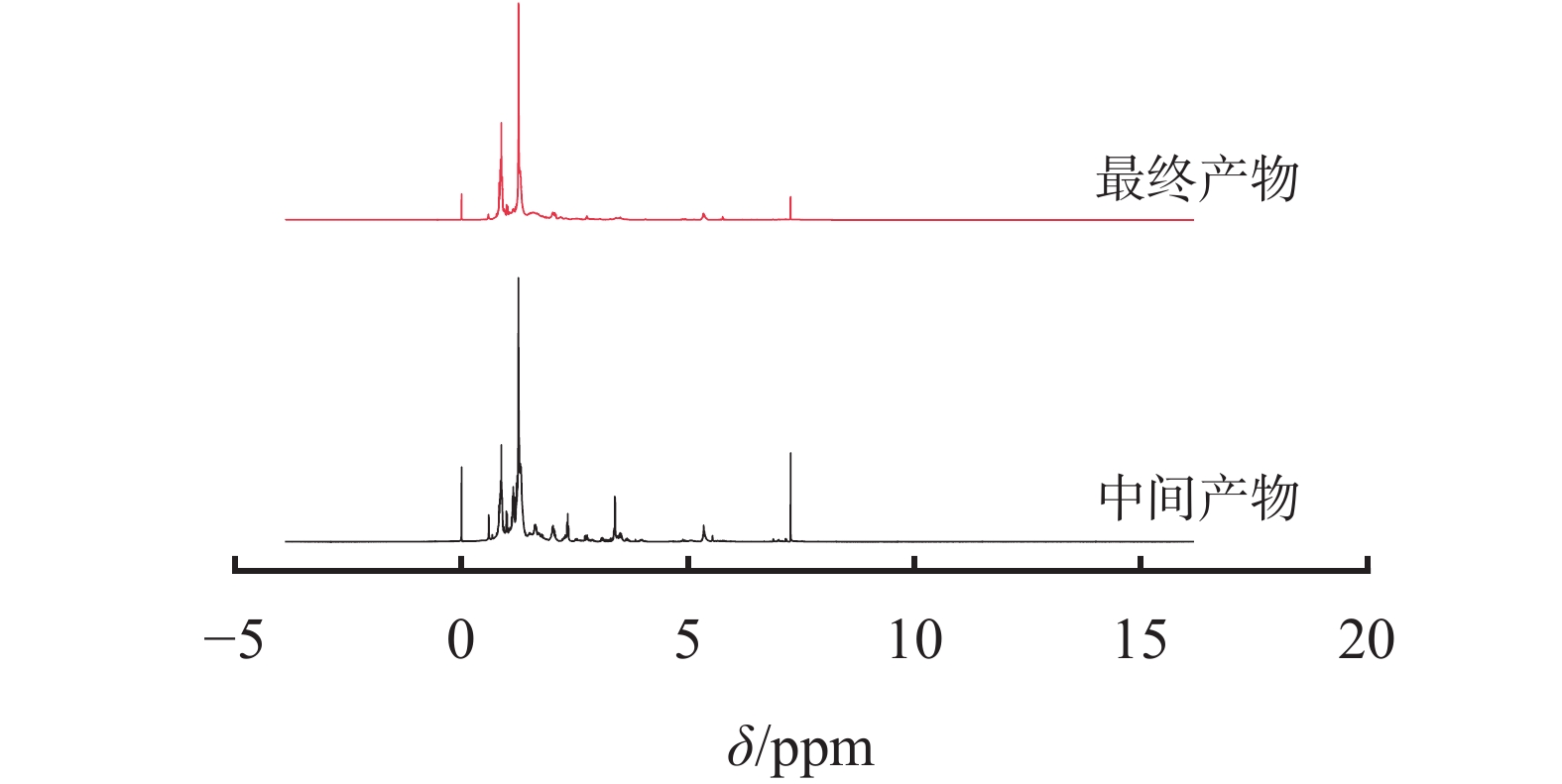

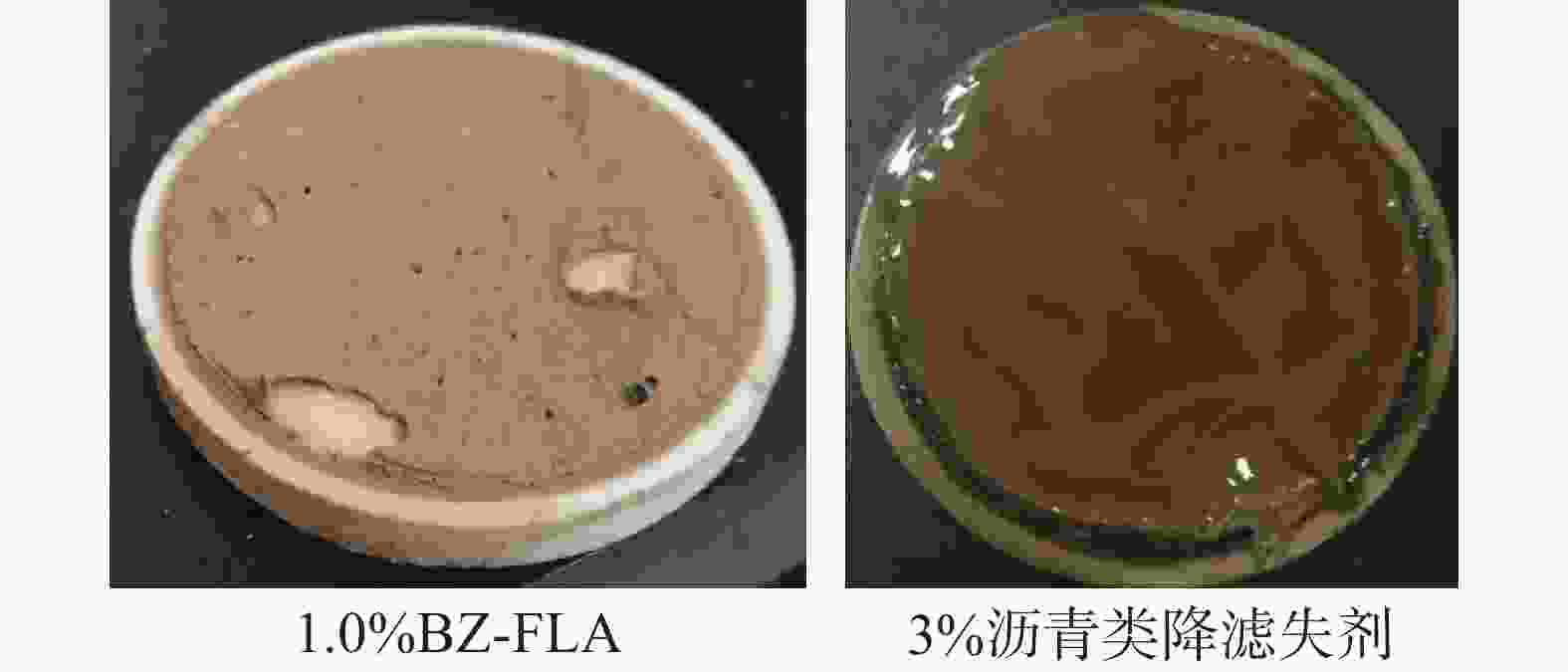

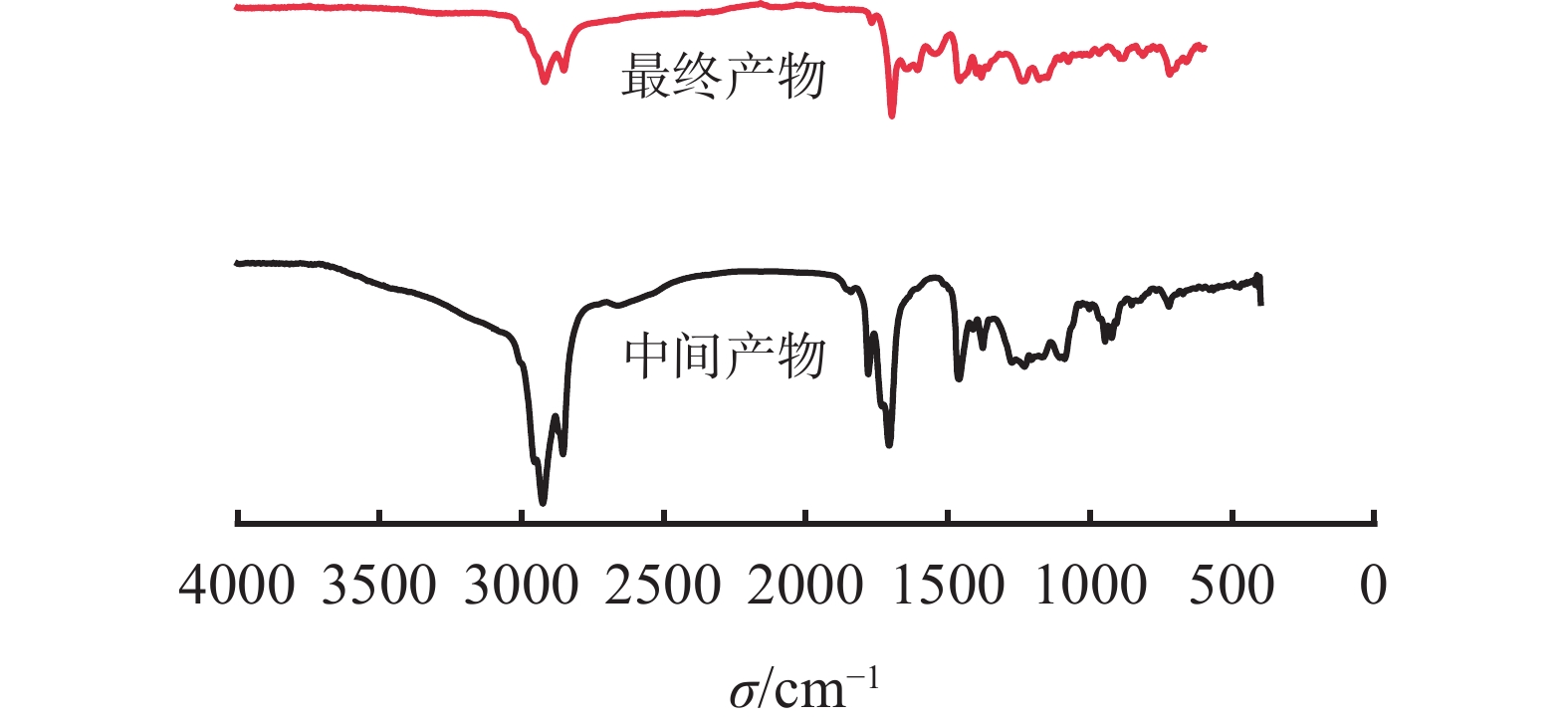

摘要: 为减少传统沥青类降滤失剂对环境的影响,并提高油基钻井液的高温封堵能力,以天然植物油加工尾料妥尔油沥青为原料,采用顺丁烯二酸酐和多元有机胺依次对其进行改性,所得产物溶于环保溶剂油,制备得到液体降滤失剂BZ-FLA。红外光谱分析和核磁共振分析表明,最终产物BZ-FLA主要为顺丁烯二酸酐改性的树脂酸和多元有机胺缩合而成的交联型妥尔油沥青酰胺树脂。分别评价液体降滤失剂在典型油基钻井液中以及无土相油基钻井液中的性能,结果表明,液体降滤失剂BZ-FLA抗温达180 ℃,加量为0.75%~1.0%时可将钻井液高温高压滤失量降至4.0 mL以内,与常规沥青降滤失剂加量3%的效果相当。BZ-FLA与沥青类和褐煤类降滤失剂复合使用,可进一步提高油基钻井液的封堵能力。BZ-FLA在无土相油基钻井液中降滤失效果同样显著。Abstract: To minimize the negative effects of conventional asphalt filter loss reducers on the environment and to enhance the plugging capacity of oil based drilling fluids at elevated temperatures, a liquid filter loss reducer BZ-FLA was produced by stepwise modifying a tall oil asphalt (a tail from natural oil processing) with maleic anhydride (MA) and polyamine, and then dissolving the product of the modification in an environmentally friendly solvent oil. IR spectroscopy and NMR analyses have proved that the final product of the aforementioned reaction, BZ-FLA, is a crosslinking tall oil asphalt amide resin which is a condensate of MA modified resin acid and polyamines. Evaluation of the performance of a typical oil based drilling fluid and a clay-free oil based drilling fluid both treated with BZ-FLA showed that BZ-FLA functions well at temperatures as high as 180 ℃. Filter loss of the typical oil based drilling fluid treated with 0.75%-1.0% BZ-FLA is less than 4.0 mL, comparable to the filtration control performance of 3% conventional asphalt filter loss reducer. Oil based drilling fluids treated with BZ-FLA, asphalt and lignite filter loss reducers exhibit enhanced plugging capacity. BZ-FLA is also equally effective in reducing filtration rate of clay-free oil based drilling fluids.

-

Key words:

- Oil based drilling fluid /

- Liquid filter loss reducer /

- Tall oil asphalt /

- Amide resin /

- Clay-free /

- Plug

-

表 1 液体降滤失剂BZ-FLA加量对油基钻井液性能的影响

BZ-FLA/

%实验

条件PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaFLHTHP/

mLh/

mmES/

V0 热滚前 34 3.5 7/5 2.0/4.5 538 热滚后 40 4.5 9/8 4.0/5.0 9.6 4.0 438 0.50 热滚前 30 3.0 4/3 2.0/3.0 536 热滚后 42 7.0 8/7 4.0/5.0 3.6 1.0 729 0.75 热滚前 35 4.0 5/4 2.0/3.0 592 热滚后 45 10.0 11/9 4.5/5.0 3.6 1.0 764 1.0 热滚前 36 4.0 6/5 3.0/4.0 637 热滚后 46 12.0 13/11 6.0/8.0 2.8 1.0 964 1.5 热滚前 38 4.0 6/5 3.0/4.5 649 热滚后 73 32.5 25/20 10.0/20.0 2.4 1.0 1379 3.0 热滚前 40 5.0 7/6 3.0/4.5 674 热滚后 80 39.0 27/26 14.0/24.0 1429 3.0* 热滚前 38 2.0 6/5 3.0/5.0 721 热滚后 51 7.0 12/11 5.5/6.0 4.6 2.5 469 注:*为沥青降滤失剂;h为泥饼厚度;热滚条件为150 ℃、16 h 表 2 液体降滤失剂BZ-FLA抗温能力评价

BZ-FLA/

%T/

℃PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaFLHTHP/

mLh/

mmES/

V0 常温 34 3.5 7/5 2.0/4.5 538 150 40 4.5 9/8 4.0/5.0 9.6 4.0 438 180 42 3.0 5/4 2.5/4.0 14.8 5.0 409 200 51 2.0 3/2 1.5/2.0 28.6 6.5 389 0.75 常温 35 4.0 5/4 2.0/3.0 592 150 45 10.0 11/9 4.5/5.0 3.6 1.0 764 180 48 6.0 7/6 3.5/6.0 7.6 1.0 680 200 38 3.0 4/3 2.0/8.0 22.0 1.5 587 1.0 常温 36 4.0 6/5 3.0/4.0 637 150 46 12.0 13/11 6.0/8.0 2.8 1.0 964 180 48 8.0 9/8 4.0/6.0 4.8 1.0 865 200 43 4.0 5/4 2.5/10.0 16.8 1.5 768 3.0* 常温 38 2.0 6/5 3.0/5.0 721 150 51 7.0 12/11 5.5/6.0 4.6 2.5 469 180 60 3.5 5/4 3.0/3.5 8.8 3.0 427 200 65 2.0 3/2 1.5/2.0 15.6 5.0 357 注:*为沥青降滤失剂;h为泥饼厚度 表 3 BZ-FLA高温高压渗透性封堵效果评价

降滤失剂 FLHPHT/

mL(150 ℃)FLHPHT/

mL(180 ℃)170-55型

砂盘170-53型

砂盘170-55型

砂盘170-53型

砂盘0 5.6 7.6 6.8 8.6 0.75% BZ-FLA 2.4 3.2 2.8 3.2 1.0% BZ-FLA 2.2 3.0 2.4 2.8 3.0%沥青类 2.4 3.4 2.8 3.0 3.0%有机褐煤 2.8 3.6 3.0 3.6 0.75% BZ-FLA+

3%沥青1.2 2.0 2.2 2.4 0.75% BZ-FLA+

3%有机褐煤1.4 2.2 2.2 2.4 注:测试压力为6.9 MPa 表 4 BZ-FLA在高密度油基钻井液中的性能

ρ/

g/cm3BZ-FLA/

%T/

℃PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaFLHTHP/

mLES/

V2.2 0.75 常温 56.0 13.5 15/14 8.5/11.0 1096 150 54.0 8.5 8/7 4.0/6.0 3.2 1359 180 55.0 5.5 6/5 3.0/6.0 4.0 1402 2.2 1.0 常温 58.0 15.5 17/16 8.5/13.0 1245 150 55.0 10.0 10/8 5.0/6.0 2.8 1365 180 57.0 6.0 8/6 4.0/5.5 3.8 1564 2.4 0.75 常温 61.0 14.0 15/14 7.5/10.5 1331 150 55.0 8.0 9/7 5.0/6.5 4.8 1457 180 52.0 5.0 6/5 3.0/4.0 5.6 1679 2.4 1.0 常温 65.0 15 17/15 8.0/12.0 1386 150 57.0 8.0 10/9 5.0/7.5 3.8 1498 180 55.0 4.0 6/5 3.5/5.5 4.8 1708 表 5 BZ-FLA在无土相油基钻井液中的性能

BZ-FLA/

%T/

℃PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaFLHTHP/

mLh/

mmES/

V0 常温 55 7.0 7/6 3.5/5.5 1079 150 46 6.0 6/5 3.5/5.0 8.4 2.5 1016 180 50 3.0 4/3 2.0/4.0 9.2 3.0 871 1.0 常温 62 7.0 7/6 3.5/6.5 1186 150 48 7.0 7/6 3.5/7.0 5.6 1.0 1004 180 52 3.0 4/3 2.0/5.0 6.4 1.0 882 1.5 常温 63 7.5 8/7 4.0/7.0 1267 150 50 7.0 8/7 4.0/7.0 3.6 1.0 1037 180 54 4.5 6/5 3.0/6.5 4.0 1.0 967 2.0 常温 66 9.5 10/8 4.5/6.0 1386 150 53 8.0 9/8 4.0/7.0 3.4 1.0 1128 180 57 6.0 6/5 3.0/6.0 3.6 1.0 1015 注:h为泥饼厚度 -

[1] 吴雄军,林永学,宋碧涛,等. 顺北油气田奥陶系破碎性地层油基钻井液技术[J]. 钻井液与完井液,2020,37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004WU Xiongjun, LIN Yongxue, SONG Bitao, et al. Oil-base drilling fluid technology for ordovician fractured formation in Shunbei oil and gas field[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004 [2] 王建华,闫丽丽,谢盛,等. 塔里木油田库车山前高压盐水层油基钻井液技术[J]. 石油钻探技术,2020,48(2):29-33. doi: 10.11911/syztjs.2020007WANG Jianhua, YAN Lili, XIE Sheng, et al. Oil-base drilling fluid technology of Kuqa piedmont high-pressure brine formation in Tarim oilfield[J]. Petroleum Drilling Technology, 2020, 48(2):29-33. doi: 10.11911/syztjs.2020007 [3] 左京杰,张振华,姚如钢,等. 川南页岩气地层油基钻井液技术难题及案例分析[J]. 钻井液与完井液,2020,37(3):294-300. doi: 10.3969/j.issn.1001-5620.2020.03.005ZUO Jingjie, ZHANG Zhenhua, YAO Rugang, et al. Technical difficulties and case analysis of oil base drilling fluid in shale gas formation in south Sichuan[J]. Drilling Fluid & Completion Fluid, 2020, 37(3):294-300. doi: 10.3969/j.issn.1001-5620.2020.03.005 [4] YAN, Lili, WANG, Jianhua, ZHANG, Jiaqi, et al. Understanding and research on the drilling fluid technology for shale gas horizontal wells in south Sichuan, China. [C]// IPTC 19587, The International Petroleum Technology Conference, Dhahran, Kingdom of Saudi Arabia, 2020. [5] 吴江,李龙,任冠龙,等. 海上复杂易垮塌地层高性能油基钻井液研发与应用[J]. 钻井液与完井液,2018,35(5):55-60. doi: 10.3969/j.issn.1001-5620.2018.05.011WU Jiang, LI Long, REN Guanlong, et al. Development and application of high performance oil base drilling fluid in complex and collapse formation offshore[J]. Drilling Fluid & Completion Fluid, 2018, 35(5):55-60. doi: 10.3969/j.issn.1001-5620.2018.05.011 [6] 王晓军,白冬青,孙云超,等. 页岩气井强化封堵全油基钻井液体系——以长宁-威远国家级页岩气示范区威远区块为例[J]. 天然气工业,2020,40(6):107-114.WANG Xiaojun,BAI Dongqing,SUN Yunchao,et al. Taking Weiyuan block, Weiyuan national shale gas demonstration area- Changning as an example[J]. Natural Gas Industry, 2020, 40(6):107-114. [7] 程荣超,王建华,闫丽丽,等. 油基钻井液用抗高温树脂类封堵剂的研制[J]. 当代化工研究,2021(5):160-162.CHENG Rongchao , WANG Jianhua, YAN Lili, et al. Development of high temperature resistant resin plugging agent for oil base drilling fluid[J]. Modern Chemical Research, 2021(5):160-162. [8] 周研,蒲晓林. 油基钻井液用降滤失剂研究现状[J]. 化学世界,2020,61(1):7-15.ZHOU Yan, PU Xiaolin. Research status of fluid loss reducers for oil - based drilling fluids[J]. Chemistry World, 2020, 61(1):7-15. [9] 黄贤斌, 蒋官澄, 邓正强. 水性丙烯酸树脂在油包水钻井液中的作用[J]. 钻井液与完井液, 2017, 34(2): 26-32.HUANG Xianbin, JIANG Guancheng, DENG Zhengqiang. The role of waterborne acrylic resin in water-in-oil drilling fluid [J]. Drilling Fluid & Completion Fluid, 2017, 34(2): 26-32. [10] MILLER J J. Metallic soaps of modified tall oil acids: US 20050137093 [P]. 2005. [11] MILLER J J. Metallic soaps of modified fatty acids and rosin acids and methods of making and using same: US 20070259790 [P]. 2007. [12] 宋胜梅,王亚明,谢惠定. 松香结晶原因分析[J]. 林产化学与工业,2001,21(3):77-82.SONG Shengmei, WANG Yaming, XIE Huiding. Analyses on cause of rosin crystallization[J]. Chemistry and Industry of Forest Products, 2001, 21(3):77-82. [13] 孙金声,黄贤斌,蒋官澄,等. 无土相油基钻井液关键处理剂研制及体系性能评价[J]. 石油勘探与开发,2018,45(4):713-718.SUN Jinsheng, HUANG Xianbin, JIANG Guancheng, et al. Development of key additives for organoclay-free oil-based drilling mud and system performance evaluation[J]. Petroleum Exploration & Development, 2018, 45(4):713-718. [14] 黄贤斌,蒋官澄,邓正强. 水性丙烯酸树脂在油包水钻井液中的作用[J]. 钻井液与完井液,2017,34(2):26-32.HUANG Xianbin, JIANG Guancheng, DENG Zhengqiang. Application of aqueous acrylic resin in invert emulsion drilling fluids[J]. Drilling Fluid & Completion Fluid, 2017, 34(2):26-32. [15] 张现斌,赵冲,王伟忠,等. 矿物油基钻井液低剪切流变行为调节技术研究[J]. 中国石油勘探,2015,20(4):63-70. doi: 10.3969/j.issn.1672-7703.2015.04.007ZHANG Xianbin, ZHAO Chong, WANG Weizhong, et al. Technologies to modify low-shear rate rheology behaviors of mineral oil based drilling fluids[J]. China Petroleum Exploration, 2015, 20(4):63-70. doi: 10.3969/j.issn.1672-7703.2015.04.007 [16] 杨小华. 松香/油脂基二元酸及其聚酰胺固化剂的制备与性能研究[D]. 中国林业科学研究院, 2013YANG Xiaohua. Synthesis, properties of rosin/oil based diacid and its polyamide curing agents [D]. Chinese Academy of Forestry, 2013. -

下载:

下载: