Laboratory Study on Clay-free Water-based Drilling Fluid in X Oilfield of Bohai Sea

-

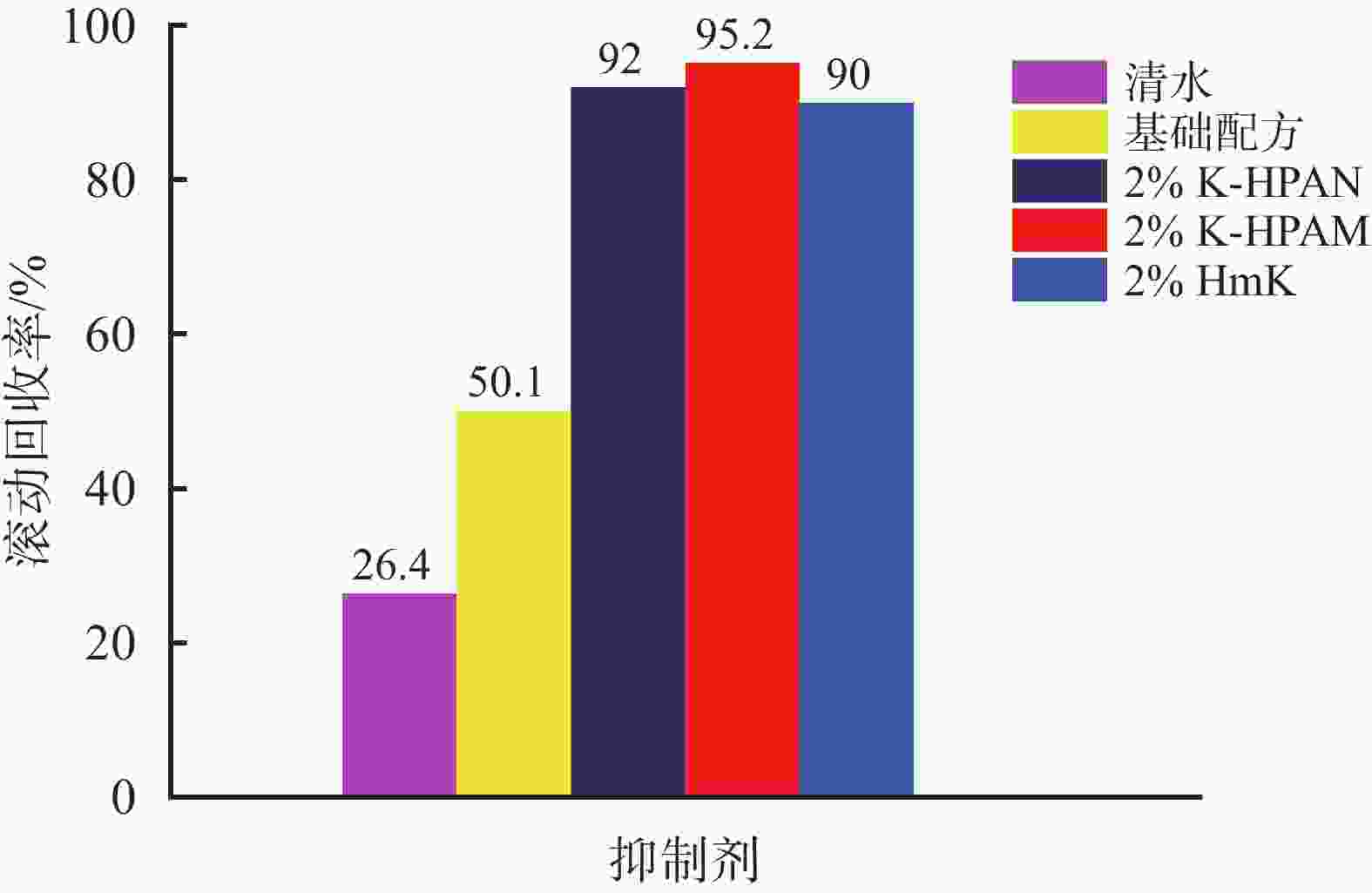

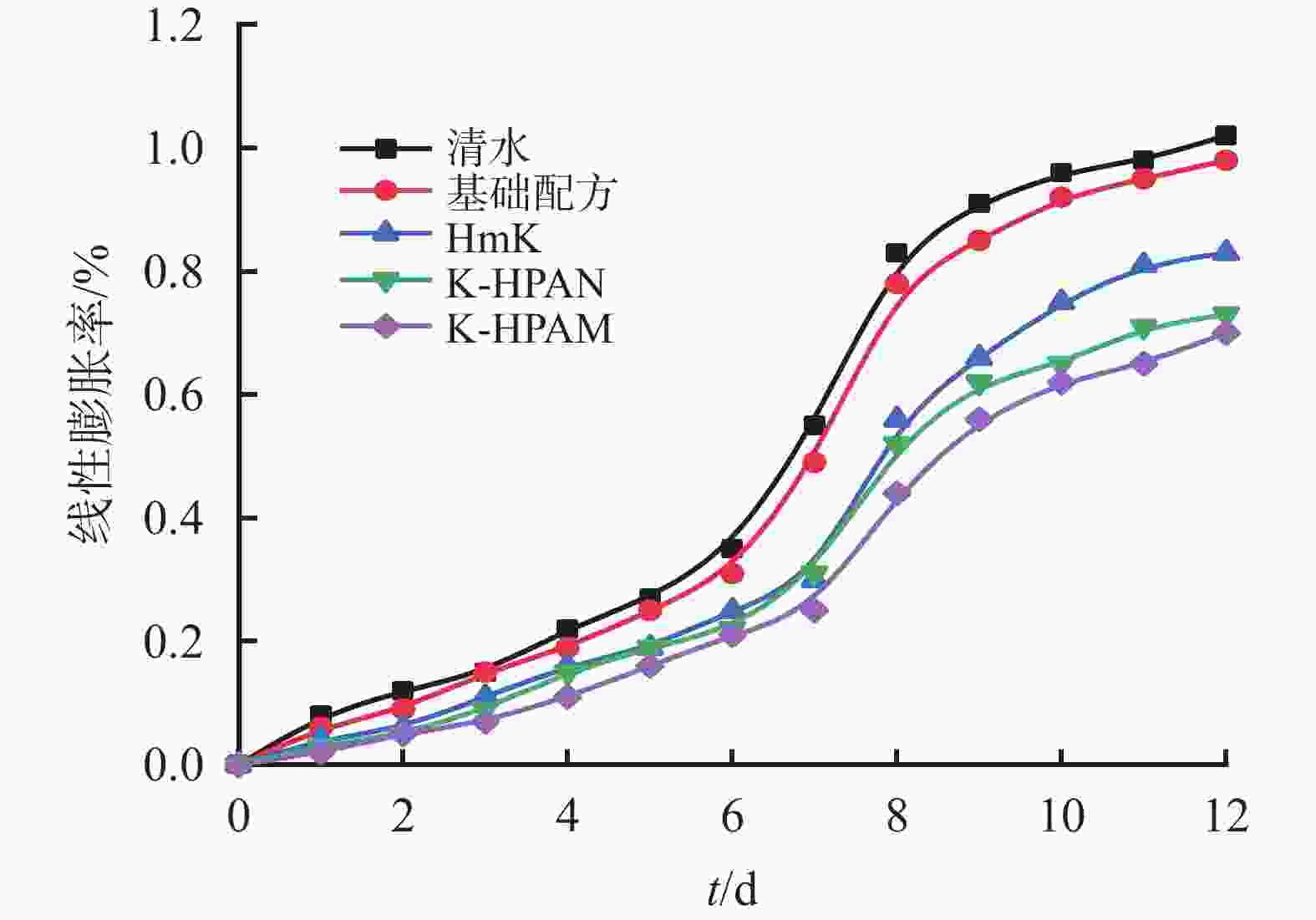

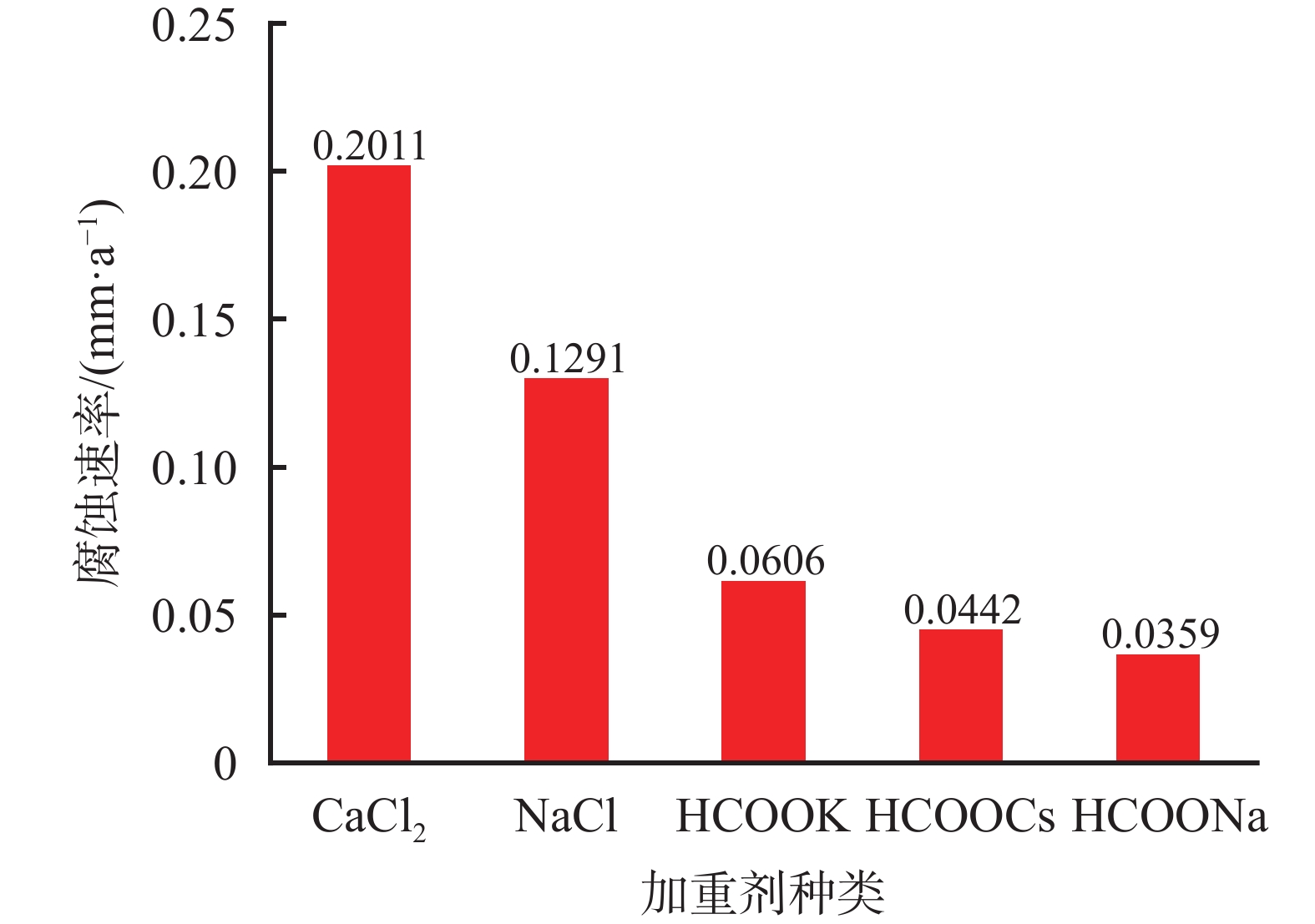

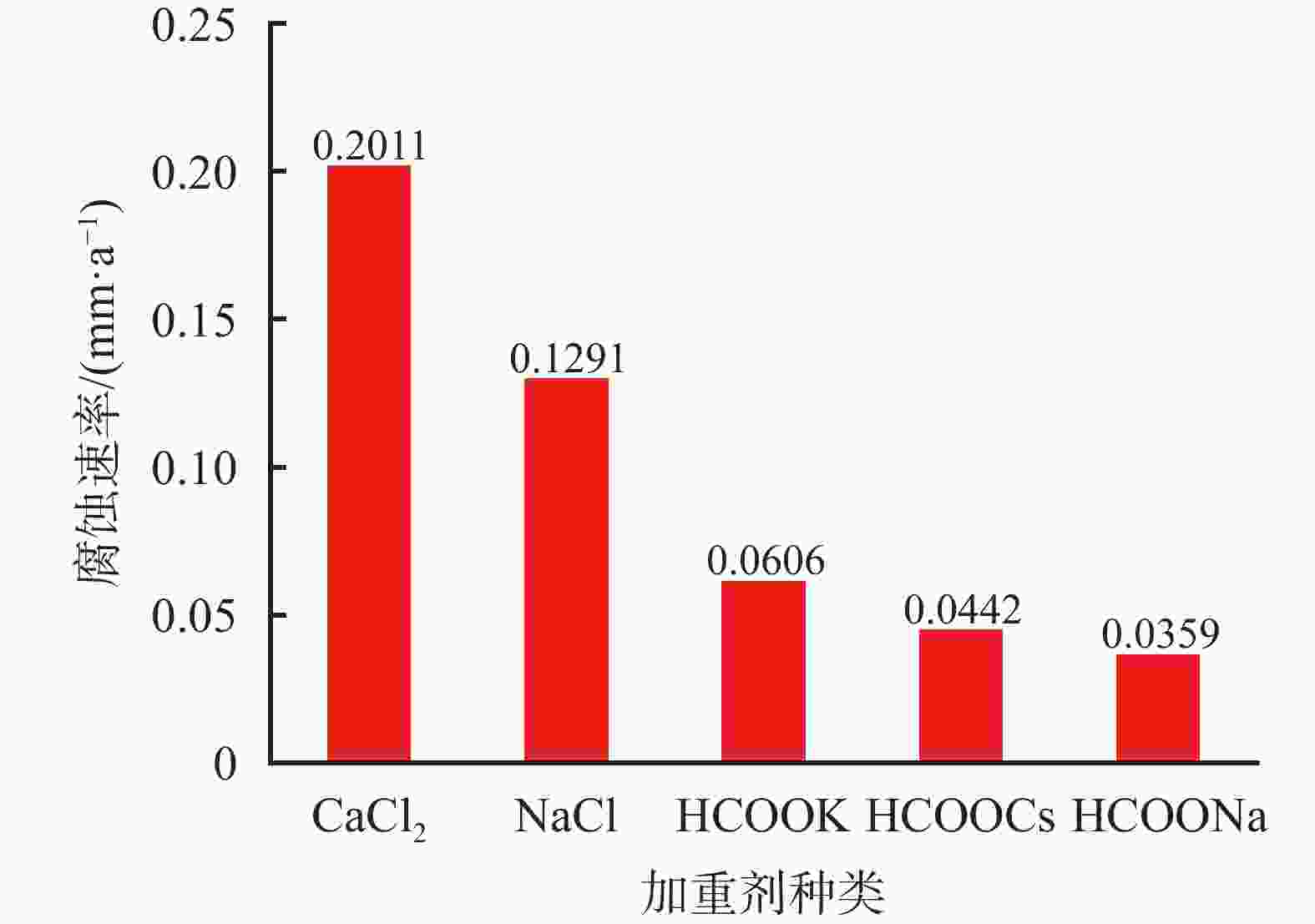

摘要: 针对渤海X油田存在的黏土分散、软泥岩缩径、起钻遇阻卡、储层段中高孔渗特征等问题,通过优选流变性调节剂、降滤失剂、润滑剂、封堵剂、抑制剂等核心处理剂,形成了一种无土相钻井液,其配方为:海水+0.2%NaOH+0.2%Na2CO3+0.3%PF-VIS+0.3%FA-367+0.6%PAC+2.0%PF-Lube+2%K-HPAM+1.5%超细碳酸钙+1.5%双溶暂堵剂+1%纳米封堵剂JF-1+HCOONa,该钻井液不含膨润土,能有效减少对储层的损害,钻井液滚动回收率在90%以上,且具有良好的热稳定性能及抗岩屑污染能力,形成的封堵层抗压强度在7 MPa以上,因优选HCOONa作加重剂,水基钻井液对WM95S管材腐蚀速率仅为0.0359 mm/a。Abstract: In the light of there are some problems in X oilfield of Bohai Sea, such as clay dispersion, soft mud shrinkage, sticking when tripping out, medium and high porosity and permeability in reservoir section. Through the optimization of rheology regulator, fluid loss reducer, lubricant, inhibitor and other main treatment agents, The formula of soilless drilling fluid suitable for Bohai X oilfield is formed, The formula is: Seawater+0.2%NaOH+0.2%Na2CO3+0.3%PF-VIS+0.3%FA-367+0.6%PAC+2.0%PF-Lube+2%K-HPAM+1.5%ultrafine calcium carbonate+1.5%dual solution temporary plugging agent+1%nanoplugging agent JF-1+HCOONa(depending on density),The drilling fluid does not use bentonite to structure, which can effectively reduce the damage to the reservoir, The rolling recovery rate of drilling fluid is over 90%. It has good thermal stability and anti cuttings pollution ability. The compressive strength of the plugging layer is more than 7 MPa, Sodium Sodium formate is selected as weighting agent of drilling fluid, and the corrosion rate of weighted drilling fluid on WM95S pipe is only 0.0359 mm/a.

-

Key words:

- Drilling fluid /

- Clay-free /

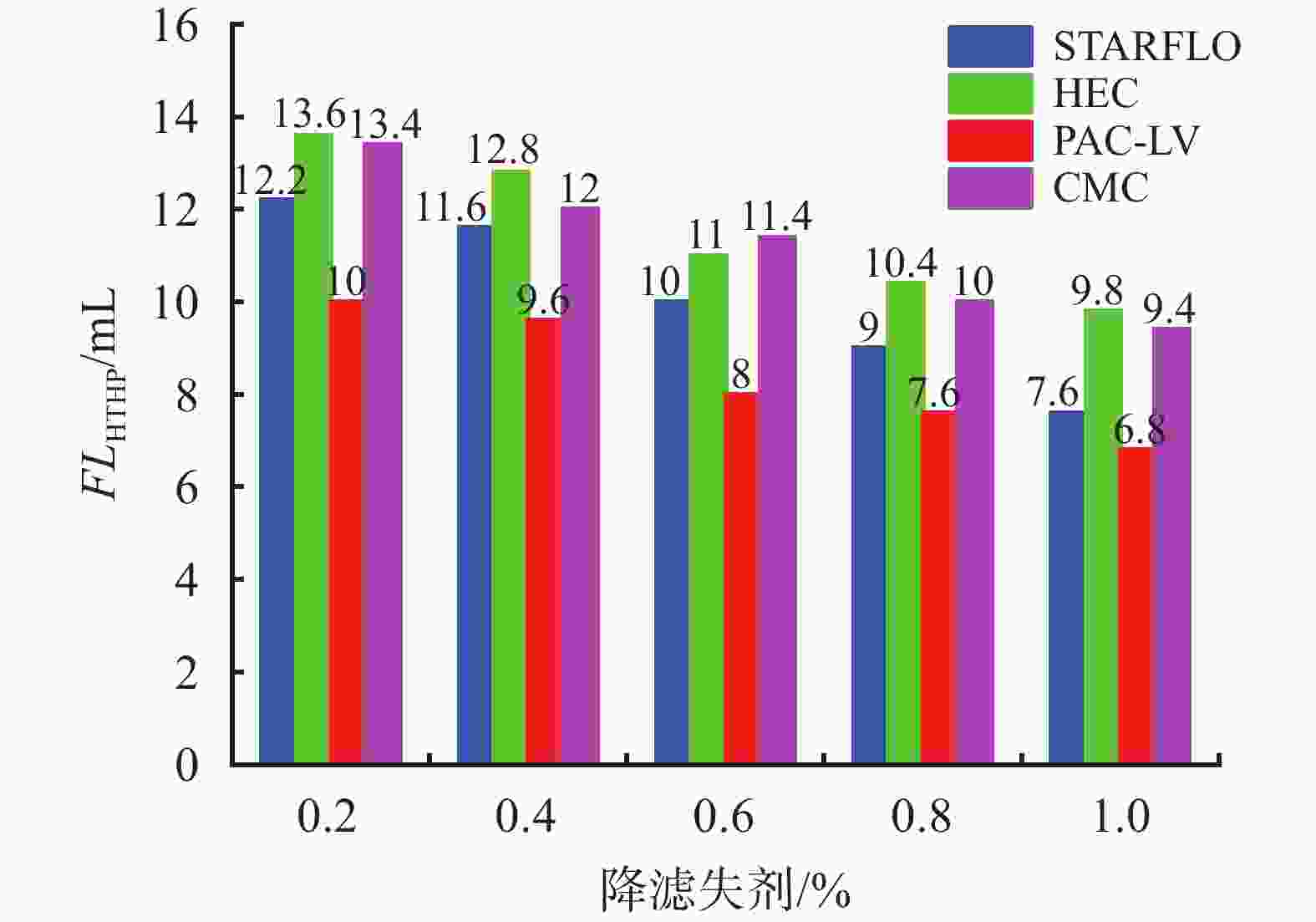

- Anti pollution /

- Corrosion resistance /

- Bohai oilfield

-

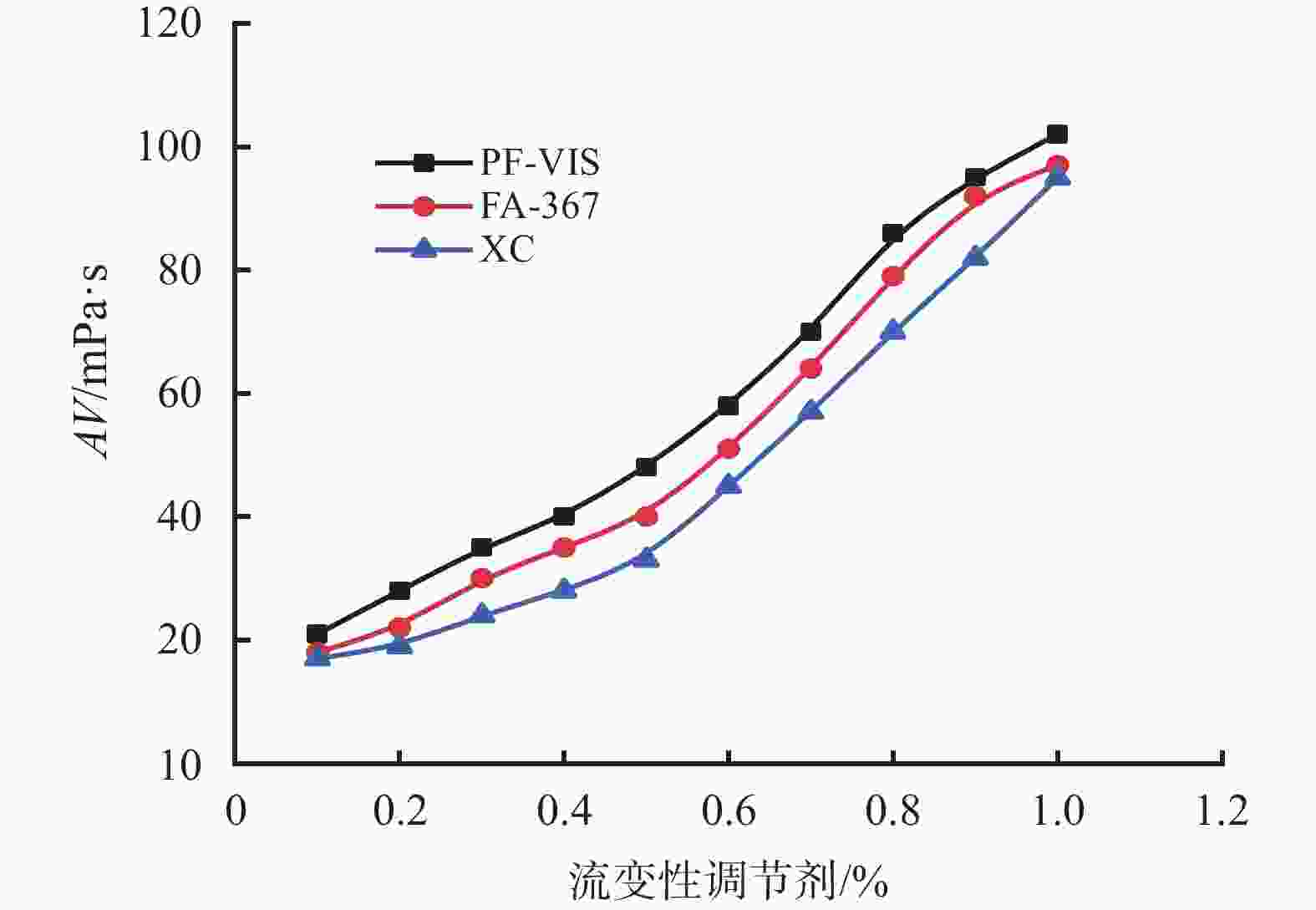

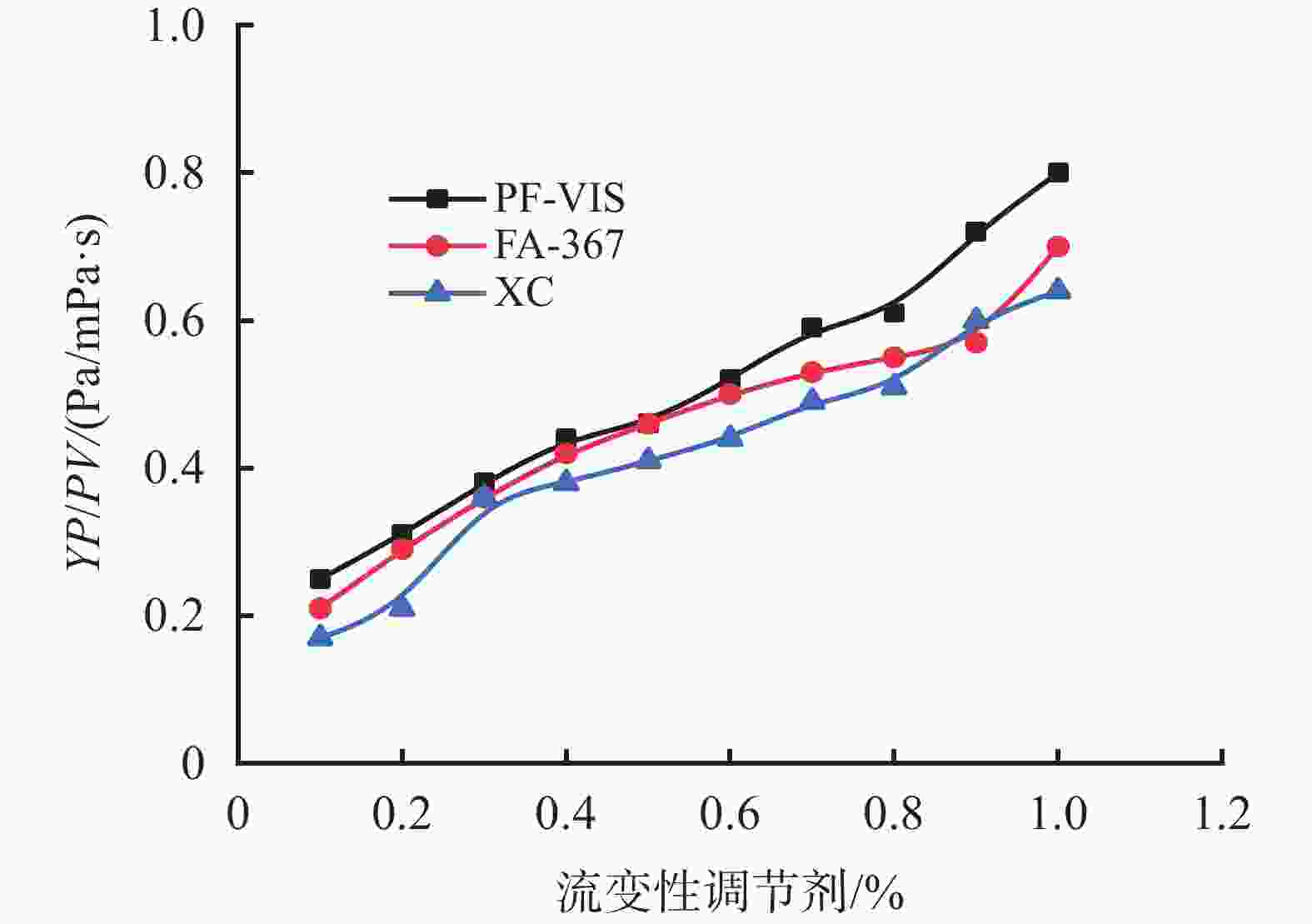

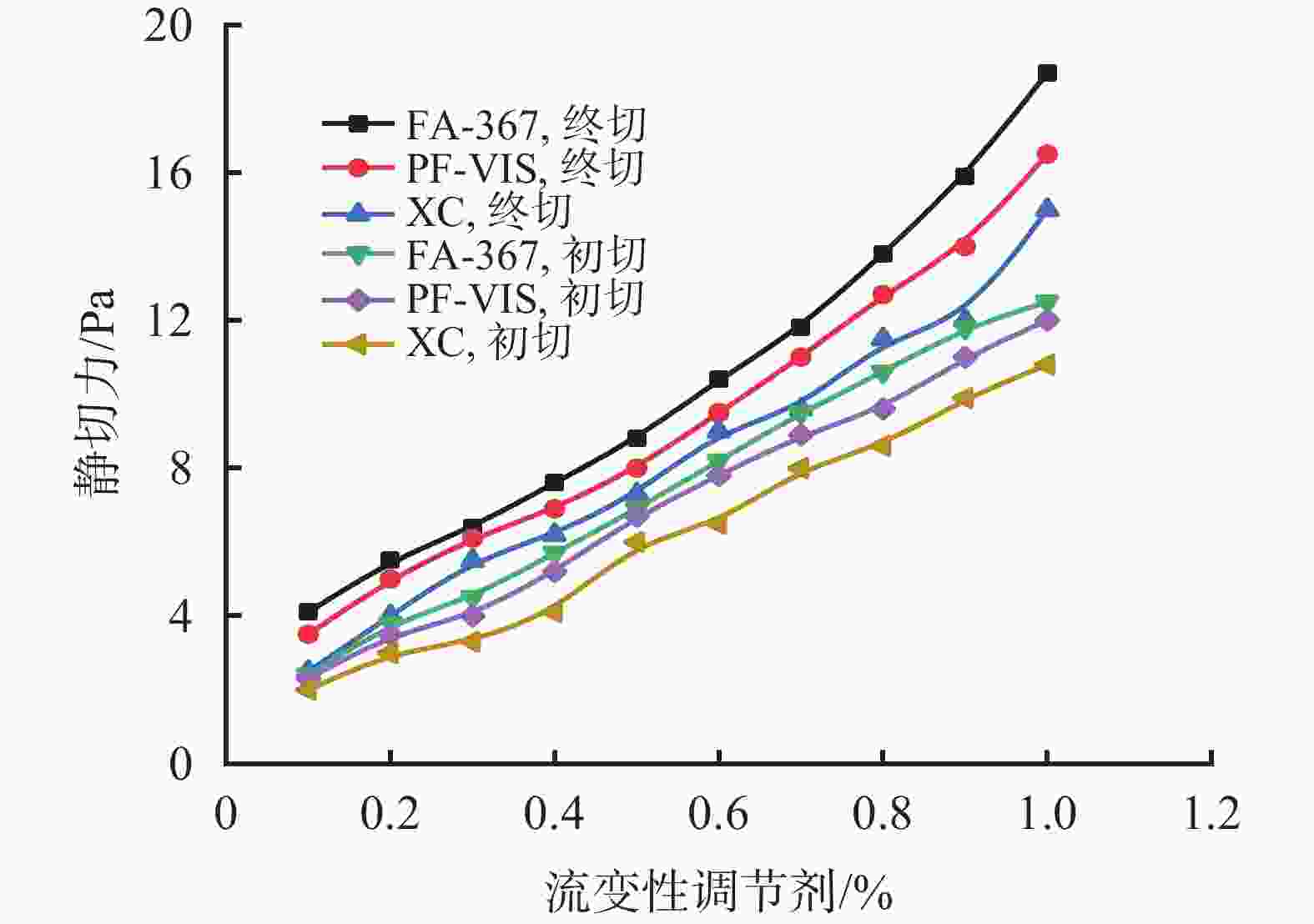

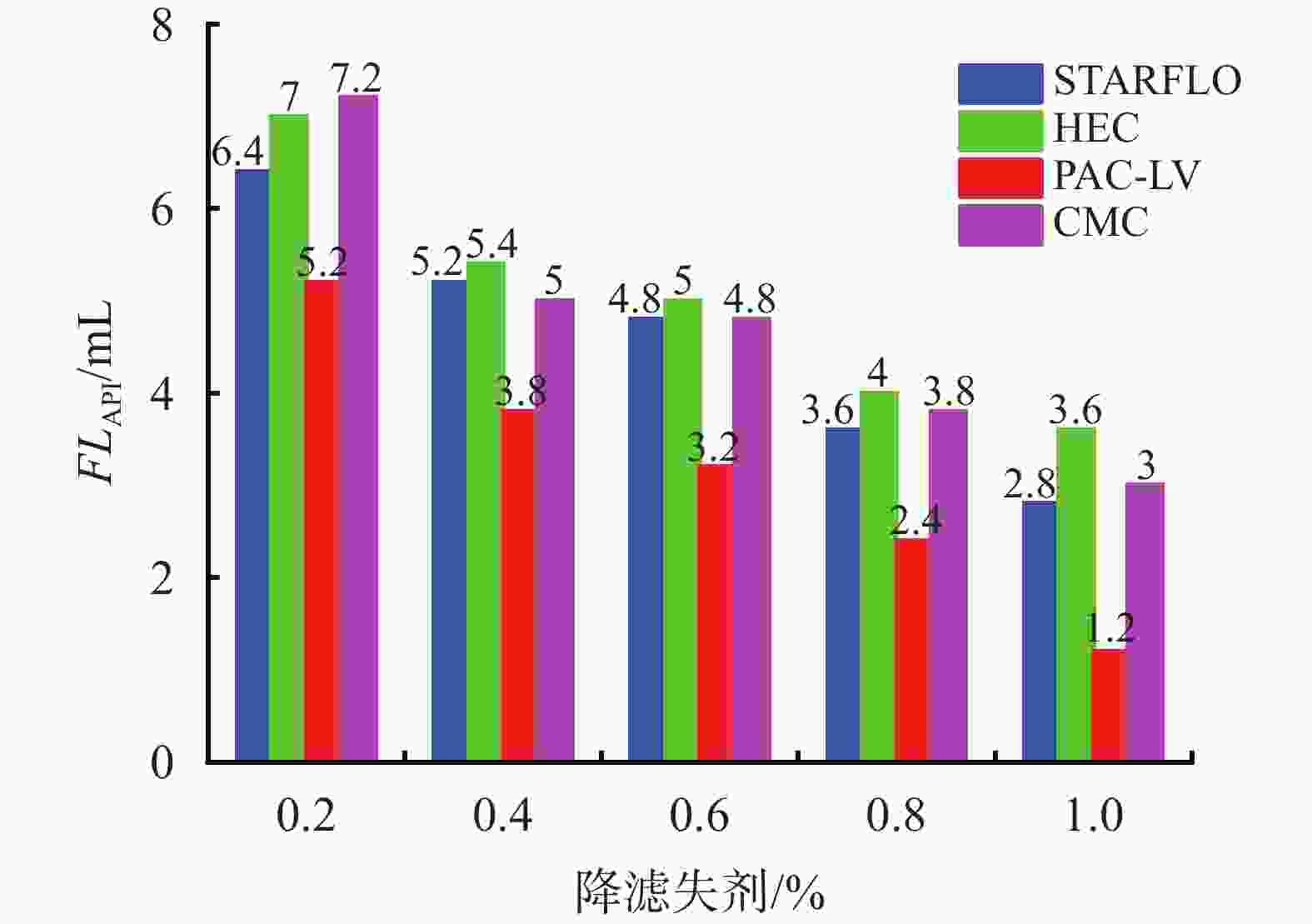

表 1 流变性能评价结果

流变性调节剂 AV/

mPa·sYP/PV/

Pa/mPa·sGel/

Pa/Pan 0.6%PF-VIS 48 0.38 4.8/8.0 0.61 0.6%FA-367 40 0.36 4.6/8.8 0.68 0.6%XC 33 0.36 4.0/6.0 0.83 0.3%PF-VIS+0.3%FA-367 46 0.42 5.0/9.2 0.59 表 2 封堵性能及封堵层强度评价结果

添加剂 P/MPa FL/mL 4%超细碳酸钙 3.5 6.4 5.0 7.2 7.0 8.8 4%双溶暂堵剂 3.5 5.6 5.0 7.0 7.0 8.2 4%纳米封堵剂JF-1 3.5 5.4 5.0 6.2 7.0 0 1.5%超细碳酸钙+

1.5%双溶暂堵剂+

1%纳米封堵剂JF-13.5 3.6 5.0 0 7.0 0 注:实验时间为30 min 表 3 耐温性能评价结果

T/

℃AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mL老化前 52 34 18 6.5/8.0 3.2 60 49 30 19 6.0/7.5 4.2 7.4 80 50 30 20 6.0/7.0 4.0 7.2 100 47 29 18 5.5/6.5 4.2 7.6 120 45 28 17 5.0/6.0 4.4 7.8 表 4 钻井液抗岩屑污染能力评价结果

岩屑/

%ρ/

g·cm−3实验

条件AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mLFLHTHP/

mL0 1.05 热滚前 52 34 18 3.2 热滚后 49 30 19 4.2 7.4 5 1.13 热滚前 55 40 15 3.2 热滚后 54 38 16 4.4 7.0 10 1.16 热滚前 58 44 14 3.0 热滚后 56 40 16 4.2 7.2 15 1.18 热滚前 67 42 25 3.6 热滚后 65 44 21 4.0 7.6 注:实验条件为60 ℃×16 h 表 5 钻井液体系性能对比结果

体系 实验

条件ρ/

g·cm−3AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mL摩擦

系数回收率/

%测试配方 热滚前 1.10 52 34 18 6.5/8.0 3.2 0.12 热滚后 1.10 49 32 17 6.0/7.5 4.2 7.4 0.11 95.2 PRD 热滚前 1.10 44 27 17 4.0/5.5 5.4 0.15 热滚后 1.10 40 24 16 3.5/5.0 6.6 9.2 0.14 93.3 EZFLOW 热滚前 1.10 46 30 16 5.0/6.0 5.2 0.12 热滚后 1.10 42 24 18 4.0/5.0 6.0 8.6 0.12 94.3 PLUS/KCl 热滚前 1.10 40 23 17 3.0/4.2 8.0 0.18 热滚后 1.10 30 16 14 2/3.6 10.4 15.6 0.16 87.3 PEM 热滚前 1.10 42 22 20 2.6/3.6 7.8 0.20 热滚后 1.10 36 24 16 2.0/4.0 9.6 14.4 0.16 88.4 -

[1] 鄢捷年. 钻井液工艺学(修订版)[M]. 2版 山东东营: 中国石油大学出版社, 2014: 88-89YAN Jienian Drilling fluid technology (Revised Edition) [M]. 2nd. Shangdong Dongying: China University of Petroleum Press, 2014: 88-89. [2] 夏庆龙,周心怀,王昕,等. 渤海蓬莱9-1大型复合油田地质特征与发现意义[J]. 石油学报,2013,34(S2):15-23. doi: 10.7623/syxb2013S2002XIA Qinglong, ZHOU Xinhuai, WANG Xi, et al. Geological characteristics and discovery significance of Penglai 9-1 large composite oilfield in Bohai[J]. Acta petrolei Sinica, 2013, 34(S2):15-23. doi: 10.7623/syxb2013S2002 [3] 崔小明. 偏苯三酸酐的生产应用及市场前景[J]. 化工科技市场,2009,32(11):24-28.CUI Xiaoming. Production, application and market prospect of trimellitic anhydride[J]. Chemical Technology Market, 2009, 32(11):24-28. [4] 何鹏. 新型植物油钻井液润滑剂的研制[J]. 现代商贸工业,2015,36(10):196-198. doi: 10.3969/j.issn.1672-3198.2015.10.095HE Peng. Development of new vegetable oil drilling fluid lubricant[J]. Modern Business Trade Industry, 2015, 36(10):196-198. doi: 10.3969/j.issn.1672-3198.2015.10.095 [5] 陈平. 钻井与完井工程[M]. 2版. 北京: 石油工业出版社, 2005: 45CHEN Ping. Drilling and completion engineering [M]. 2nd. Beijing: Petroleum Industry Press, 2005: 45 [6] 王平全, 周世良. 钻井液处理剂及其作用原理[M]北京: 石油工业出版社, 2003: 210WANG Pingquan, ZHOU Shiliang. Drilling fluid treatment agent and its action principle [M] Beijing: Petroleum Industry Press, 2003: 210 [7] 周长虹,崔茂荣. 国内水溶性钻井液降滤失剂的研究与应用[J]. 精细石油化工,2006(5):1-5. doi: 10.3969/j.issn.1003-9384.2006.05.001ZHOU Changhong, CUI Maorong. Research and application of water soluble fluid loss additive for drilling fluid in China[J]. Speciality Petrochemicals, 2006(5):1-5. doi: 10.3969/j.issn.1003-9384.2006.05.001 [8] 王中华,杨小华. 水溶性纤维素类钻井液处理剂制备与应用进展[J]. 精细与专用化学品,2009,17(9):15-18. doi: 10.3969/j.issn.1008-1100.2009.09.005WANG Zhonghua, YANG Xiaohua. Progress in preparation and application of water soluble cellulose drilling fluid treatment agents[J]. Fine and Special Chemicals, 2009, 17(9):15-18. doi: 10.3969/j.issn.1008-1100.2009.09.005 [9] 王中华, 钻井液处理剂实用手册, [M]2版, 北京: 中国石化出版社, 2016: 249WANG Zhonghua, practical manual of drilling fluid treatment agent, [M] 2nd, Beijing: China Petrochemical Press, 2016: 249 [10] 郭太现,刘春成,吕洪志,等. 蓬莱19-3油田地质特征[J]. 石油勘探与开发,2001(2):26-28. doi: 10.3321/j.issn:1000-0747.2001.02.008GUO Taixian, LIU Chuncheng, LYU Hongzhi, et al. Geological characteristics of 19-3 oilfield[J]. Petroleum Exploration and Development, 2001(2):26-28. doi: 10.3321/j.issn:1000-0747.2001.02.008 [11] 赵向阳,张小平,陈磊,等. 甲酸盐钻井液在长北区块的应用[J]. 石油钻探技术,2013,41(1):40-44. doi: 10.3969/j.issn.1001-0890.2013.01.008ZHAO Xiangyang, ZHANG Xiaoping, CHEN Lei, et al. Application of formate drilling fluid in Changbei block[J]. Petroleum Drilling Techniques, 2013, 41(1):40-44. doi: 10.3969/j.issn.1001-0890.2013.01.008 -

下载:

下载: