Study and Application of Environmentally Friendly High Performance Water Base Drilling Fluid

-

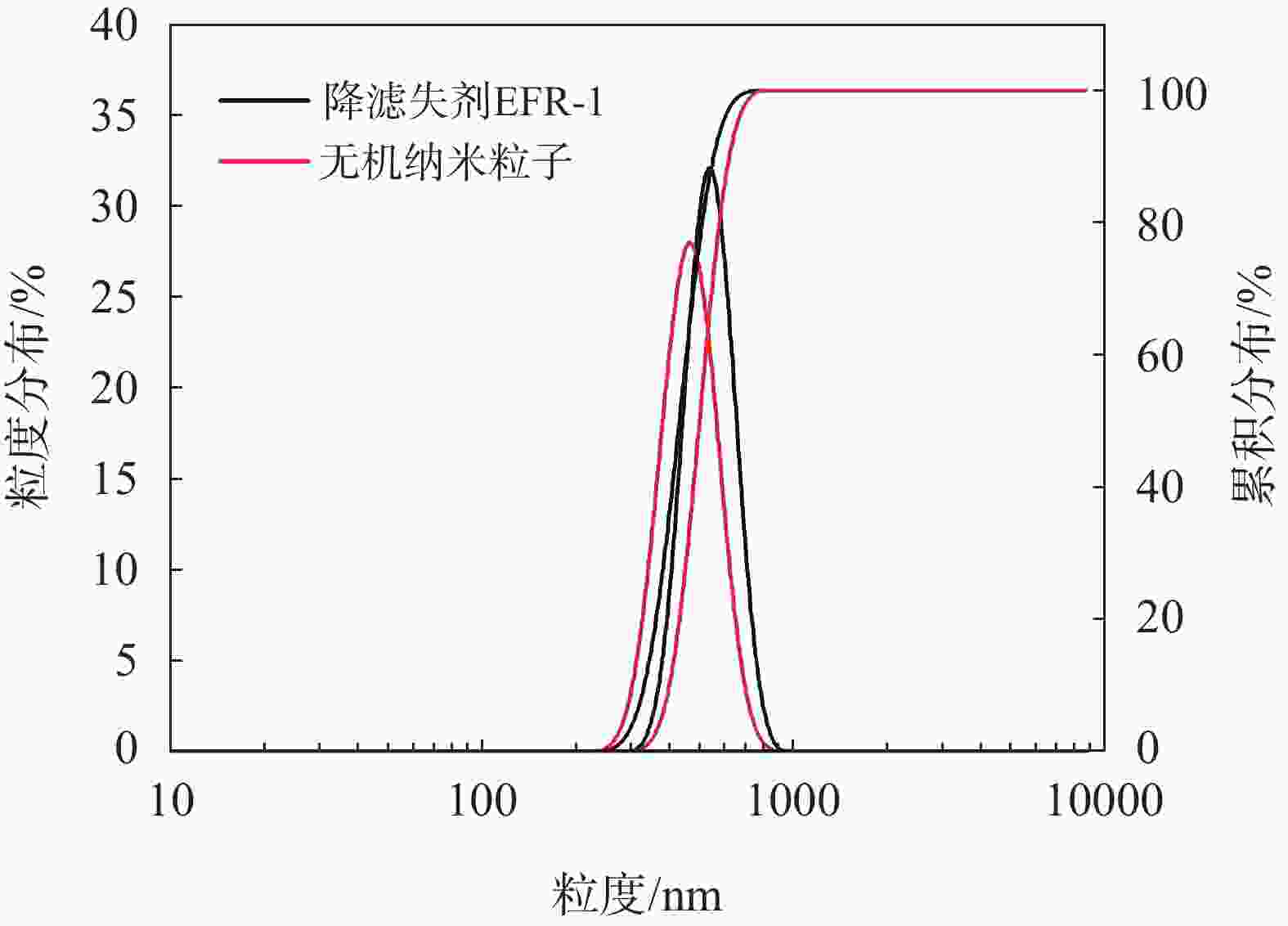

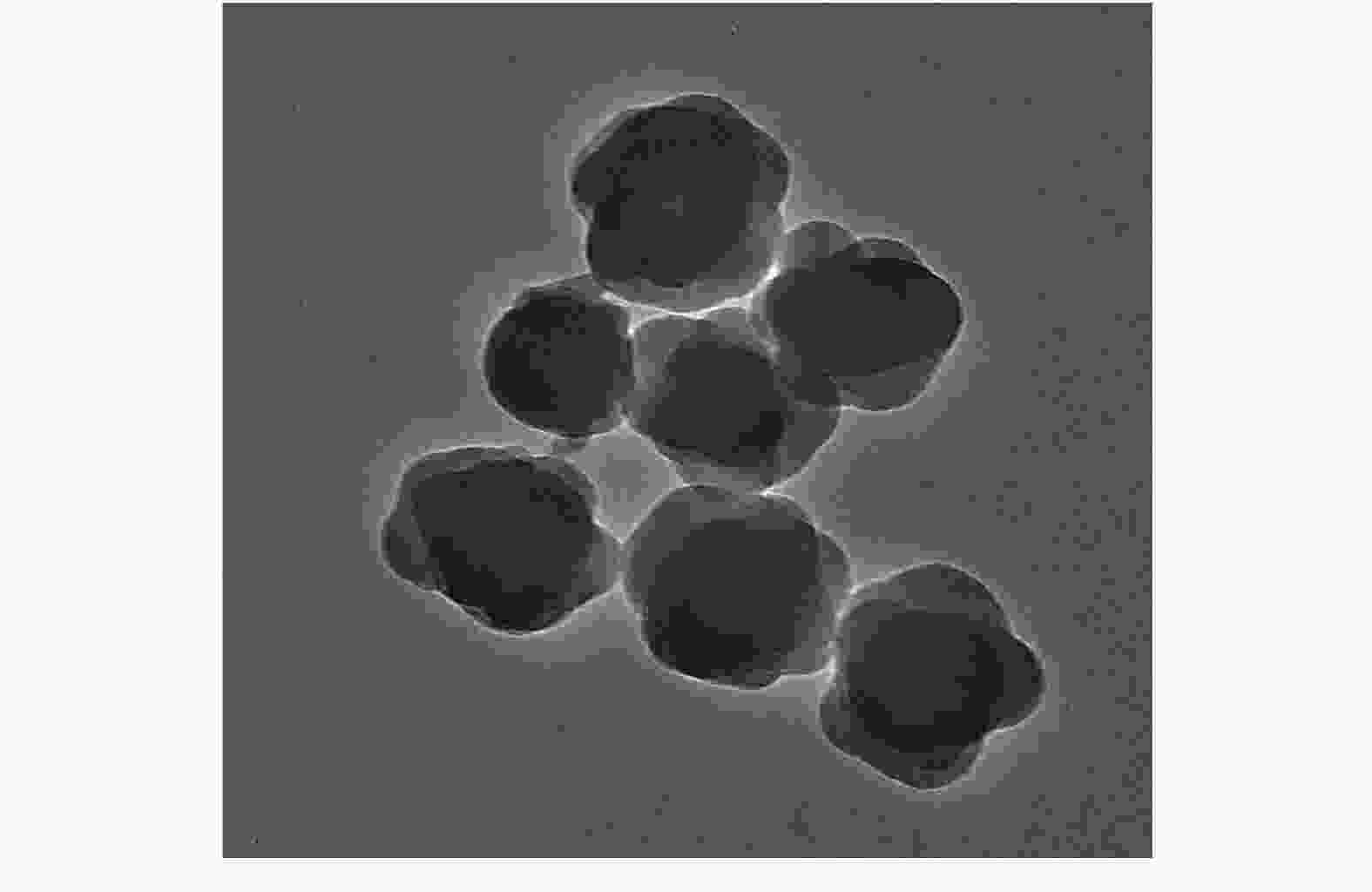

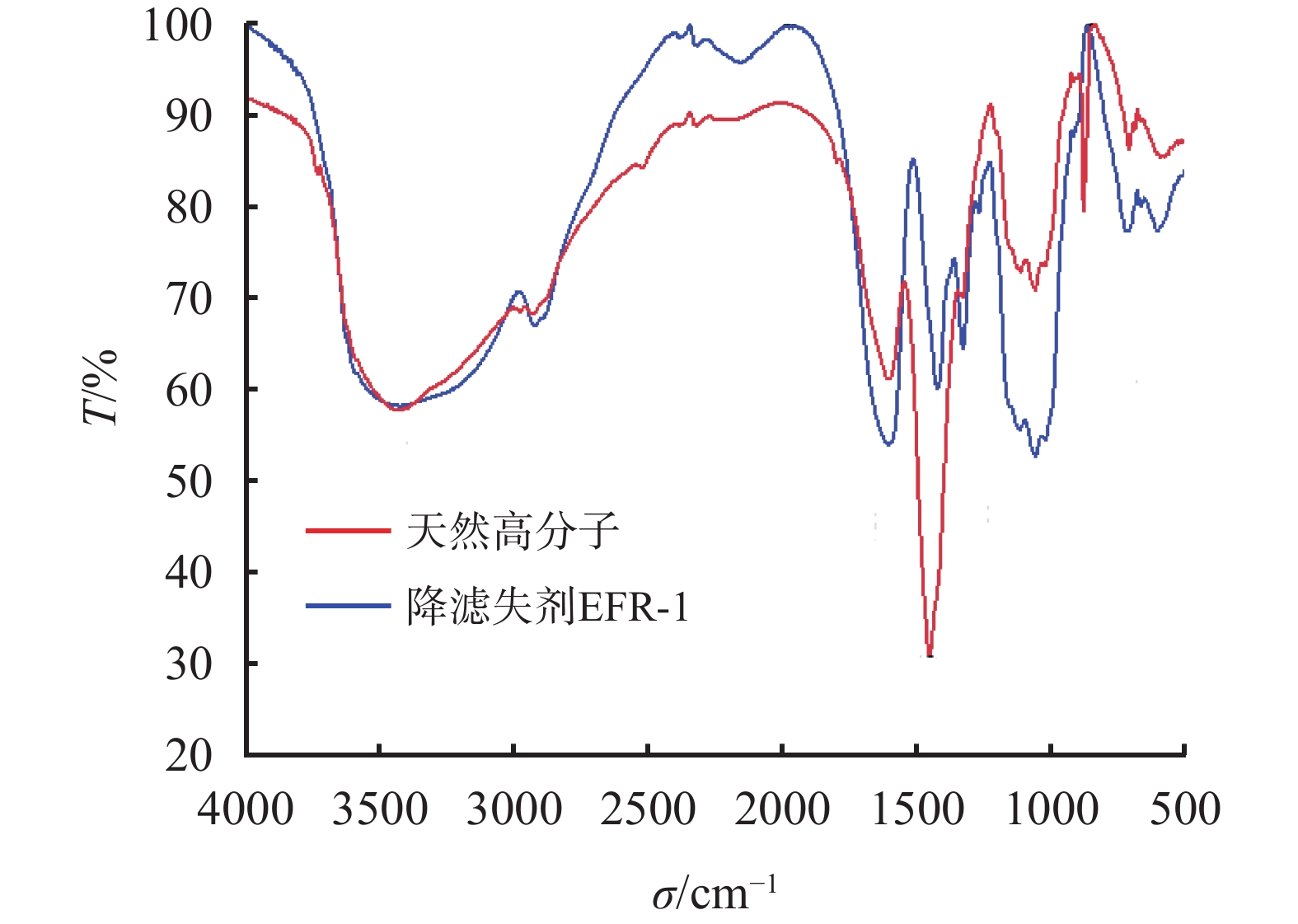

摘要: 针对高性能水基钻井液体系配方复杂、性能调控难度大、生物毒性与重金属超标等技术难题,采用疏水缔合与接枝复合改性方法,设计、研发了一种基于天然高分子/无机纳米复合材料的环保降滤失剂EFR-1,并对其性能进行评价。结果表明,EFR-1的抗温可达170 ℃,在饱和盐水中API滤失量仅为14.8 mL,生物毒性EC50值为96 500 mg/L,生物降解性BOD5/CODCr为18.56%,较好地解决了降滤失剂抗温、耐盐与环境友好性能相互制约的问题。构建了抗高温为170 ℃的高性能环保水基钻井液体系HPHB,该钻井液的流变、滤失性能稳定,配方组成简单,高温高压滤失量仅为7.8 mL,生物毒性EC50值为56 800 mg/L。目前高性能环保水基钻井液体系HPHB已在胜利油田、新疆准中区块等现场应用20余口井,施工顺利,实验井段的井径扩大率≤5%。在显著提升钻井液工程性能的基础上,实现了绿色无毒,为深层超深层、海洋深水、非常规等复杂油气藏的绿色开发提供了技术支撑。Abstract: In the field application of high performance water based drilling fluids, several technical problems have been encountered, such as complex composition, properties difficult to adjust and control, as well as excessive biotoxicity and heavy metals. To solve these problems, an environmentally friendly filter loss reducer EFR-1 was developed with a natural high molecular weight polymer and an inorganic nanocomposite through hydrophobic association and grafting modification. Laboratory evaluation of the EFR-1 filter loss reducer showed that EFR-1 is able to function normally at high temperatures up to 170 ℃. Saturated saltwater drilling fluids treated with EFR-1 have filtration rate of only 14.8 mL, EC50 (biological toxicity) of 96 500 mg/L and BOD5/CODCr (biodegradability) of 18.56%. The use of EFR-1 helped solve the mutually restraining problems such as temperature resistance, salt resistance and environmental friendliness. A high performance water based drilling fluid HPHB was developed with EFR-1. HPHB, a drilling fluid of simple composition, has stable rheology and filtration property in field operations, its HTHP filter loss is only 7.8 mL and EC50 of 56 800 mg/L. HPHB has been successfully used on 20 wells drilled in Shengli Oilfield and Zhunzhong block in Xinjiang. Hole sections drilled with this HPHB drilling fluid have percent hole enlargement of less than 5%. The HPHB drilling fluid is not only technically feasible, but also environmentally friendly, it has provided a technical support to the “green” development of complex oil and gas reservoirs buried in deep/ultra-deep formations and in deep waters, as well as the “green” development of unconventional oil and gas reservoirs.

-

表 1 环保降滤失剂EFR-1的降滤失性能

EFR-1/

%热滚

条件FLAPI/

mLFLHTHP/

mLAV/

mPa·sPV/

mPa·sYP/

Pa0 热滚前 23.0 10.5 6.5 4.0 热滚后 30.0 84.0 4.0 3.5 0.5 0.5 热滚前 9.2 21.0 13.0 8.0 热滚后 8.2 40.6 20.5 14.0 6.5 1.0 热滚前 6.2 33.5 21.0 12.5 热滚后 5.2 24.8 42.5 31.0 11.5 1.5 热滚前 6.0 47.0 30.0 17.0 热滚后 4.8 20.4 58.5 41.0 17.5 注:热滚条件为160 ℃、16 h;高温高压滤失量测试条件为160 ℃、3.5 MPa 表 2 环保降滤失剂EFR-1的抗高温性能

T热滚/

℃FLAPI/

mLAV/

mPa·sPV/

mPa·sYP/

Pa热滚前 6.2 33.5 21.0 12.5 160 5.2 42.5 31.0 11.5 170 7.2 27.5 21.0 6.5 180 13.6 9.0 8.0 1.0 注:热滚时间为16 h;基浆:膨润土浆+1%EFR-1 表 3 环保降滤失剂EFR-1的抗盐性能

NaCl/

%热滚

条件FLAPI/

mLAV/

mPa·sPV/

mPa·sYP/

Pa0 热滚前 6.2 33.5 21.0 12.5 热滚后 5.2 42.5 31.0 11.5 4 热滚前 7.8 22.5 13.0 9.5 热滚后 7.2 13.0 9.0 4.0 10 热滚前 9.2 23.0 15.0 8.0 热滚后 8.8 10.0 7.0 3.0 20 热滚前 13.2 30.0 18.0 12.0 热滚后 11.2 16.5 12.0 4.5 饱和 热滚前 13.8 26.0 16.0 10.0 热滚后 14.2 22.5 19.0 3.5 注:热滚条件为160 ℃、16 h;基浆:4%淡水膨润土浆+1%EFR-1 表 4 环保降滤失剂EFR-1的抗钙性能

CaCl2/

%热滚

条件FLAPI/

mLAV/

mPa·sPV/

mPa·sYP/

Pa0 热滚前 6.2 33.5 21.0 12.5 热滚后 5.2 42.5 31.0 11.5 1.0 热滚前 8.6 22.5 17.0 5.5 热滚后 6.4 24.5 18.0 6.5 1.5 热滚前 13.2 23.0 15.0 8.0 热滚后 10.8 20.0 14.0 6.0 2.0 热滚前 22.0 9.5 6.0 3.5 热滚后 18.0 10.0 7.0 3.0 注:热滚条件为160 ℃、16 h;基浆:4%淡水膨润土浆+1%EFR-1 表 5 高性能环保水基钻井液的流变、滤失性能

T热滚/

℃AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH 热滚前 51.5 36.0 15.5 5.0/9.5 2.8 10.0 160 40.5 29.5 11.0 4.0/7.0 2.4 7.6 9.5 170 38.5 28.0 10.5 4.0/6.5 2.8 7.8 9.5 表 6 高性能环保水基钻井液的环保性能

体系配方 pH 色度 生物毒性EC50/

mg·L−1重金属元素/

mg·kg−1Pb Cd Cr HPHB 9.5 200 56 800 1.32 0.07 0.10 聚磺防塌 11.0 1000 8400 5.91 2.23 7.81 表 7 高性能环保水基钻井液热滚后的抗污染性能

污染物 AV/

mPa·sPV/

mPa·sYP/

PaGel/

PaFLAPI/

mLpH HPHB 40.5 29.5 11.0 4.0/7.0 2.8 10.0 20%NaCl 47.0 35.0 12.0 4.5/8.5 3.6 9.0 1%CaCl2 56.5 40.0 16.5 6.5/9.5 4.2 9.0 10%评价土 54.0 36.0 18.0 7.0/11.0 3.6 9.5 注:热滚条件为160 ℃、16 h 表 8 高性能环保水基钻井液的储层保护性能

K0/

mDKd /

mDKd/K0 /

%Kd'/

mDKd'/K0/

%0.833 0.716 85.94 0.753 90.36 表 9 现场钻井液分段性能

井深/

mρ/

g·cm−3FV/

sPV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH Cl−/

mg·L−13070 1.20 40 12 4.0 1.0/4.0 3.8 / 8.5 51 000 3578 1.25 52 22 7.5 2.0/8.0 3.0 / 9.0 67 810 3850 1.34 54 24 9.5 2.0/11.0 3.0 8.8 9.5 78 514 4458 1.52 56 27 12.0 3.0/13.0 3.2 8.8 9.0 85 759 4860 1.54 55 30 12.0 3.0/14.0 3.0 8.6 9.5 83 765 5102 1.55 58 31 12.0 4.0/14.0 1.8 8.0 9.0 81 771 5372 1.68 64 42 12.0 3.0/14.0 1.6 8.0 9.0 85 760 5437 1.66 68 44 12.0 3.0/14.0 1.4 8.0 9.0 85 080 5902 1.63 72 40 13.0 4.0/15.0 1.8 8.4 9.0 81 535 6644 1.69 70 38 15.0 4.0/15.0 2.0 8.4 9.0 79 762 6745 1.81 76 42 18.0 4.5/16.0 1.8 8.2 9.0 74 445 6815 1.88 66 45 15.0 3.0/11.0 1.6 8.2 8.5 70 990 -

[1] 刘均一,郭保雨,王勇,等. 环保型水基钻井液在胜利油田的研究与应用[J]. 钻井液与完井液,2020,37(1):64-70.LIU Junyi, GUO Baoyu, WANG Yong, et al. Study and application of environmentally friendly water base drilling fluid in Shengli Oilfield[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):64-70. [2] 路保平. 中国石化石油工程技术新进展与发展建议[J]. 石油钻探技术,2021,49(1):1-10. doi: 10.11911/syztjs.2021001LU Baoping. New progress and development proposals of Sinopec’s petroleum engineering technologies[J]. Petroleum Drilling Techniques, 2021, 49(1):1-10. doi: 10.11911/syztjs.2021001 [3] 刘均一,郭保雨. 页岩气水平井物化协同封堵强化井壁水基钻井液研究[J]. 西安石油大学学报(自然科学版),2019,34(2):86-92.LIU Junyi, GUO Baoyu. Study on water-based drilling fluid for strengthening wellbore of horizontal shale gas wells[J]. Journal of Xi'an Shiyou University(Natural Science) , 2019, 34(2):86-92. [4] 韩来聚,李公让. 胜利油田钻井环保技术进展及发展方向[J]. 石油钻探技术,2019,47(3):89-94.HAN Laiju, LI Gongrang. Development trends, and outlook for drilling environmental protection technologies in the Shengli Oilfield[J]. Petroleum Drilling Techniques, 2019, 47(3):89-94. [5] 司西强,王中华. 绿色高性能水基钻井液研究进展及发展趋势[J]. 应用化工,2019,47(3):89-94.SI Xiqiang, WANG Zhonghua. Research progress and development trend of green high performance water-based drilling fluids[J]. Applied Chemical Industry, 2019, 47(3):89-94. [6] 王治法,刘贵传,刘金华,等. 国外高性能水基钻井液研究的最新进展[J]. 钻井液与完井液,2009,25(6):69-72. doi: 10.3969/j.issn.1001-5620.2009.06.021WANG Zhifa,LIU Guichuan,LIU Jinhua,et al. Overseas New progresses in high performance water base drilling fluid research[J]. Drilling Fluid & Completion Fluid, 2009, 25(6):69-72. doi: 10.3969/j.issn.1001-5620.2009.06.021 [7] LIU J Y, GUO B Y, LI G R. , et al. Synthesis and performance of environmental-friendly starch-based filtrate reducers for water-based drilling fluids[J]. Fresenius Environmental Bulletin, 2019, 28(7):5618-5623. [8] 张启根,陈馥,刘彝,等. 国外高性能水基钻井液技术发展现状[J]. 钻井液与完井液,2007,24(3):74-77. doi: 10.3969/j.issn.1001-5620.2007.03.022ZHANG Qigen, CHEN Fu, LIU Yi, et al. Development of high performance water base muds abroad[J]. Drilling Fluid & Completion Fluid, 2007, 24(3):74-77. doi: 10.3969/j.issn.1001-5620.2007.03.022 [9] 刘均一. 高性能环保水基钻井液技术研究新进展[J]. 精细石油化工进展,2018,19(6):33-38.LIU Junyi. New research progress on high performance environmental friendly water-based drilling fluid technology[J]. Advances in Fine Petrochemicals, 2018, 19(6):33-38. [10] 李家学, 张绍俊, 李磊, 等. 环保型高性能水基钻井液在山前超深井中的应用[J]. 钻井液与完井液, 2017, 34(5): 20-26.LI Jiaxue, ZHANG Shaojun, LI Lei, et al. Application of environmentally friendly high performance water base muds in ultra deep well drilling in Piedmont Area[J]. Drilling Fluid & Completion Fluid, 2017, 34(5):20-26. [11] 于得水,徐泓,吴修振,等. 满深1井奥陶系桑塔木组高性能防塌水基钻井液技术[J]. 石油钻探技术,2020,48(5):49-54.YU Deshui, XU Hong, WU Xiuzhen, et al. High performance anti-sloughing water based drilling fluid technology for Well Manshen 1 in the Ordovician Sangtamu Formation[J]. Petroleum Drilling Techniques, 2020, 48(5):49-54. [12] AKPOMIE K G, CONRADIE J. Synthesis characterization and regeneration of an inorganic–organic nanocomposite (ZnO biomass) and its application in the capture of cationic dye[J]. Scientific Reports, 2020, 10(1):550-564. doi: 10.1038/s41598-019-57328-4 [13] 陈秋枝. 基于超分子相互作用自组装有机/无机纳米复合材料[D]. 哈尔滨: 哈尔滨工业大学, 2011: 8-13.CHEN Qiuzhi. Preparation of organic/inorganic nanocomposites based on superamolecular self-assembly[D]. Harbin: Harbin Institute of Technology, 2011: 8-13. -

下载:

下载: