Rheological Characteristics of Oil Base Drilling Fluids and Its Mathematical Model under Coupled HTHP Conditions

-

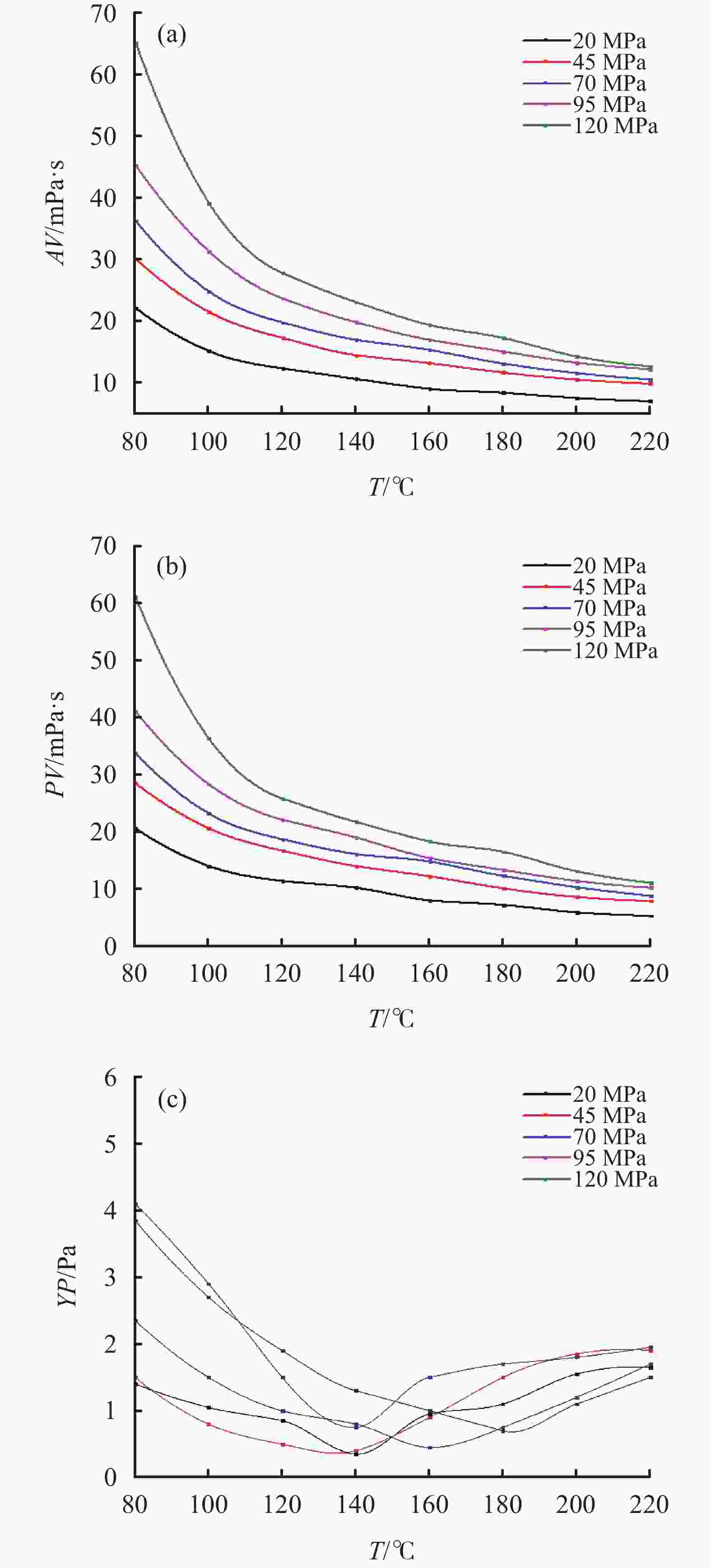

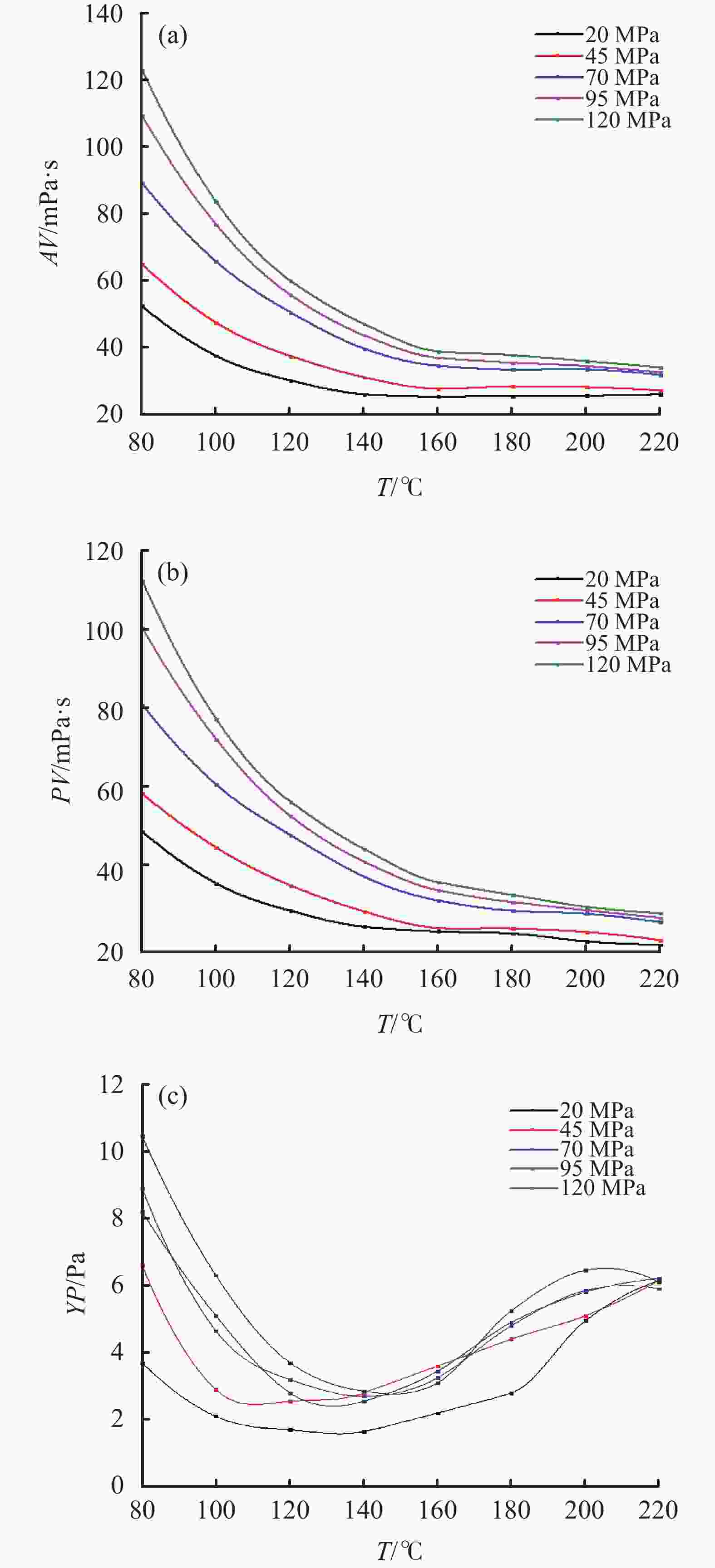

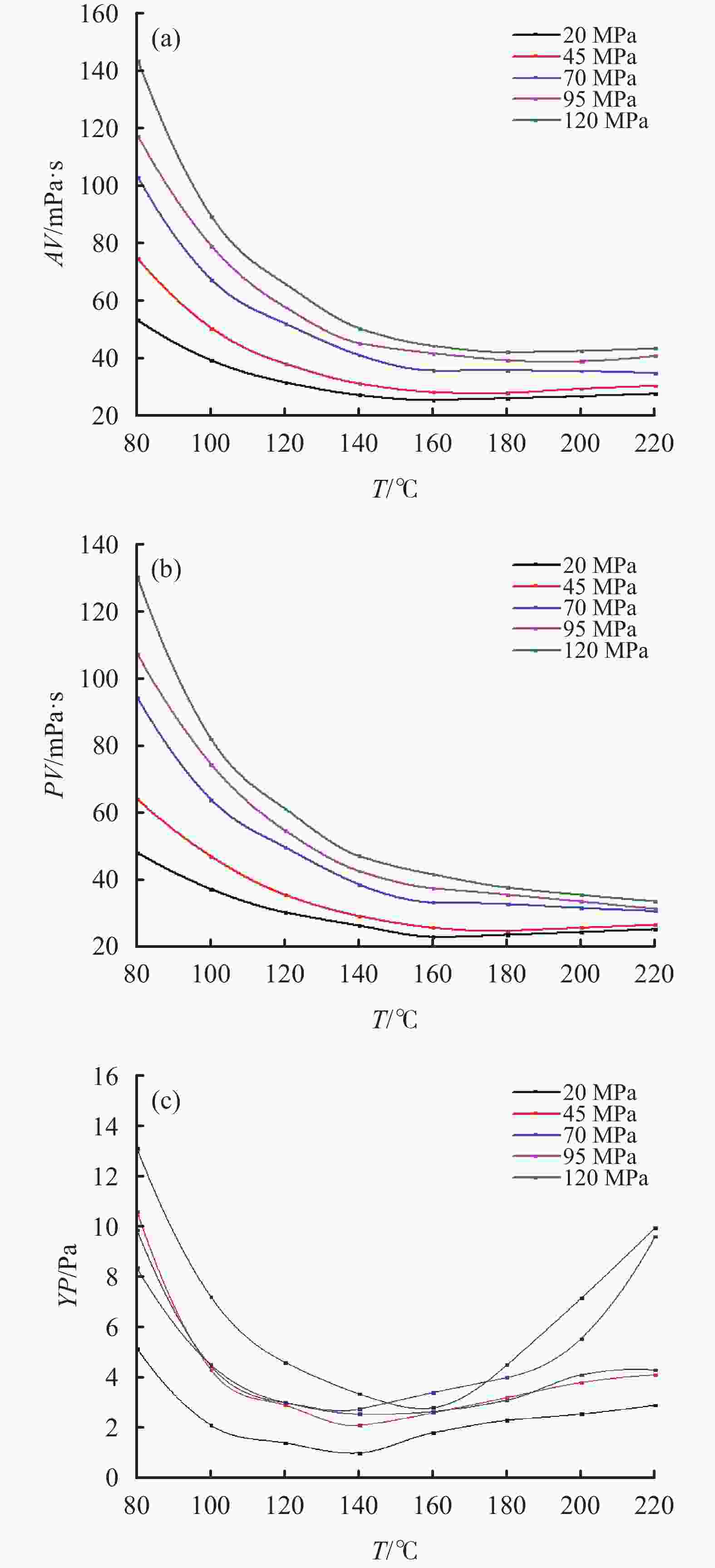

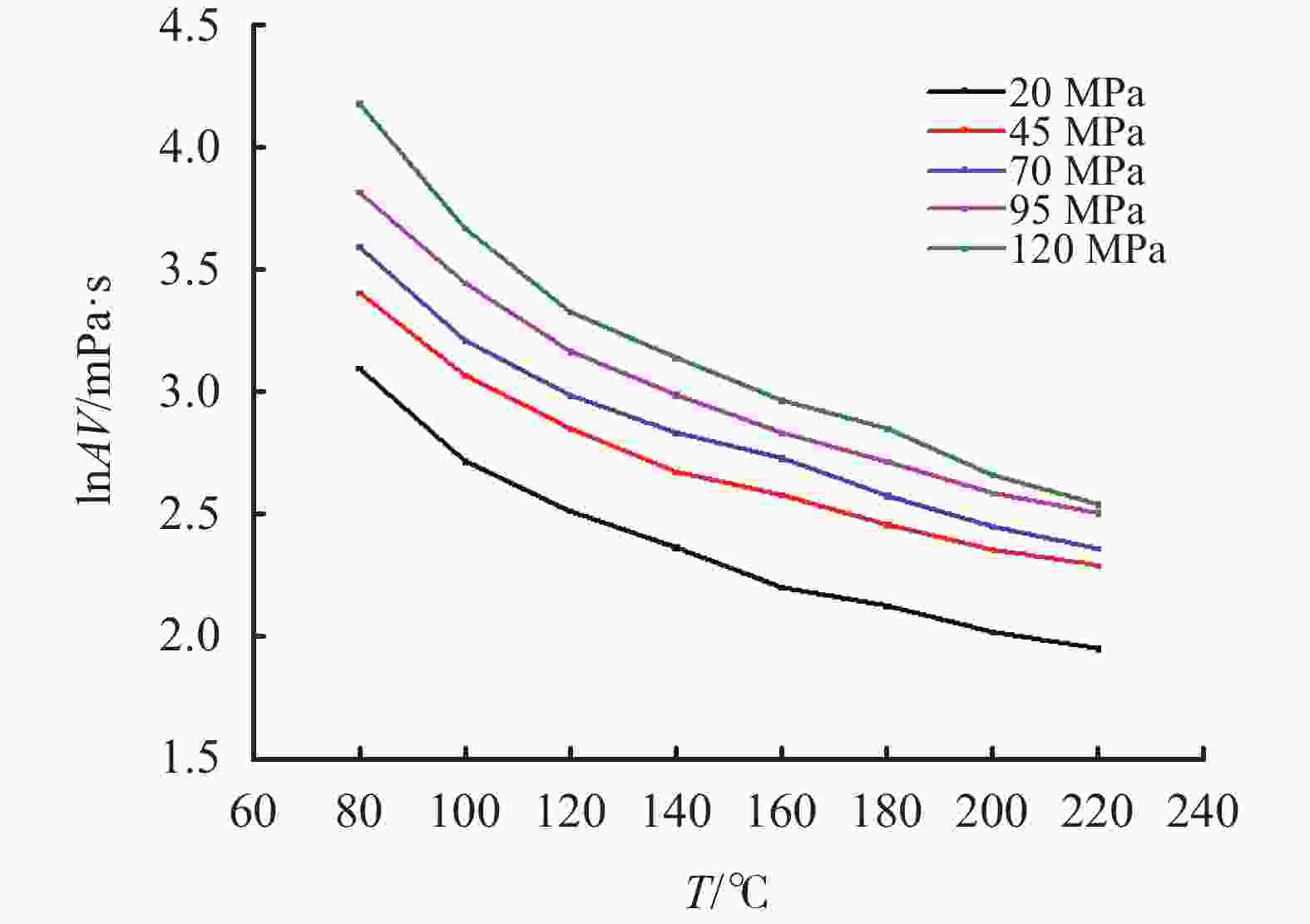

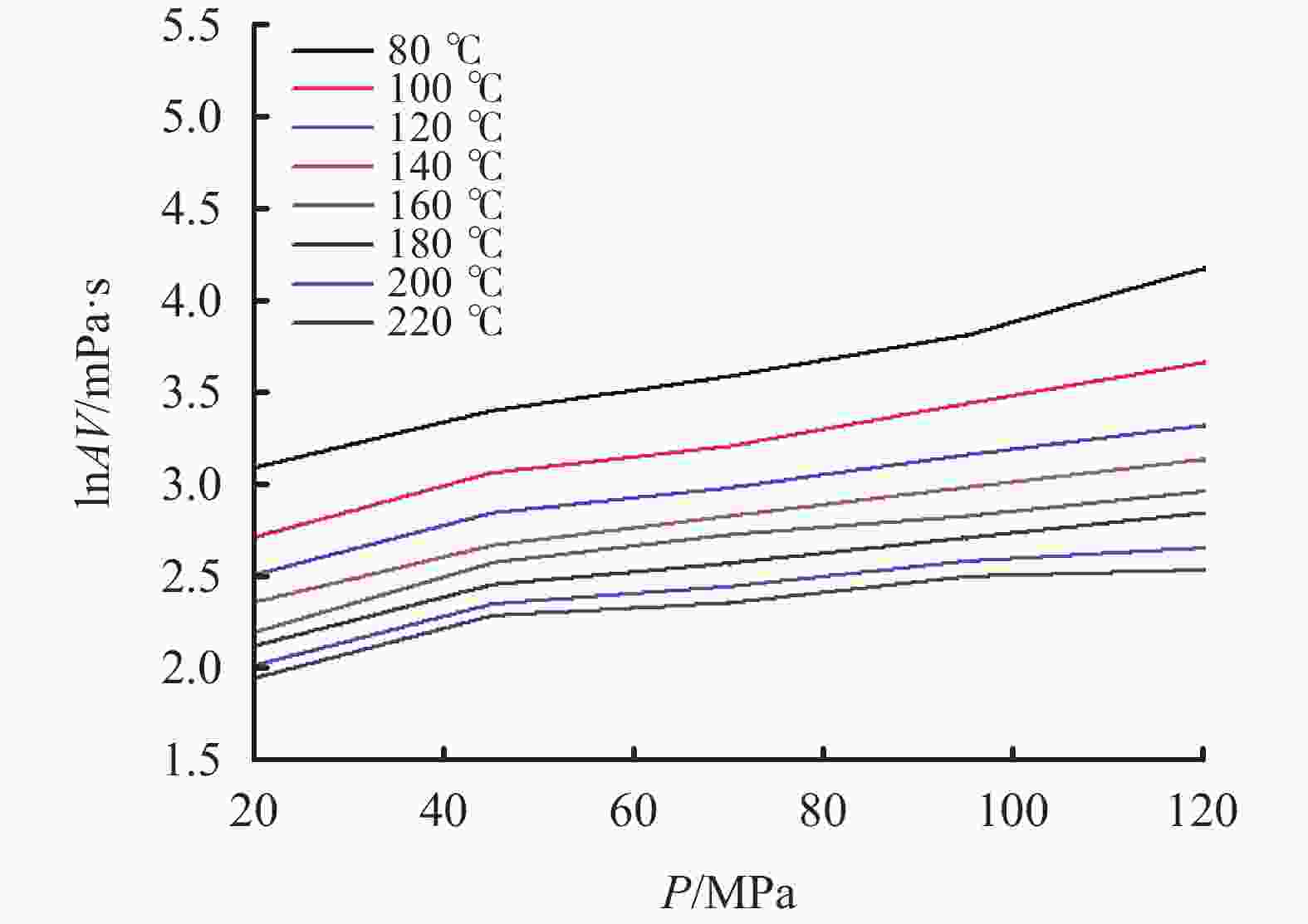

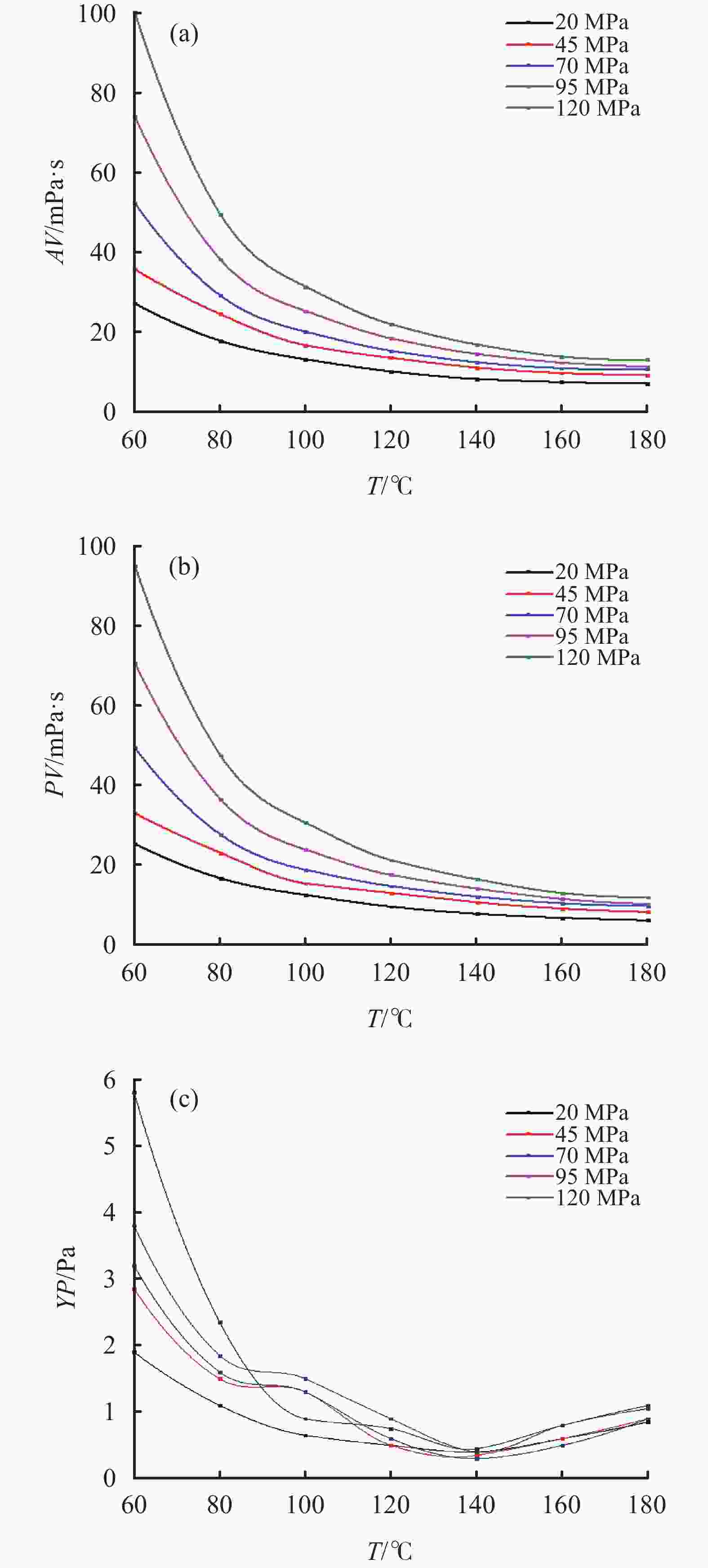

摘要: 为了探究高温、高压耦合条件下温度、压力对油基钻井液流变性能的影响规律,利用超高密度高温高压钻井液流变仪Fann iX77分别测试了各个高温、高压耦合条件下密度为1.4、1.8、2.2、2.4 g/cm3的抗高温油基钻井液体系的流变特性。结果显示,油基钻井液表观黏度和塑性黏度随温度的升高而逐渐降低,随压力的增大而逐渐增大;动切力随温度的升高表现出先增高后降低的趋势;当温度超过一定值时(160 ℃左右),高温作用对各个高密度油基钻井液流变性的影响都将大大减弱。将所测得的各个高温、高压耦合节点条件下的流变参数进一步分析后得到油基钻井液的温度、压力二元数学模型,误差分析结果显示,该模型对各密度体系的实验测量数据均具有良好的拟合性,可决系数R均大于0.96,因此该数学模型能够较为精确地预测出各个温度、压力耦合条件下油基钻井液的流变性能。Abstract: Abstract To investigate the effects of temperature and pressure on the rheological characteristics of oil based drilling fluids under coupled high temperature and high pressure, the rheology of four high temperature oil based drilling fluids with densities of 1.4 g/cm3, 1.8 g/cm3, 2.2 g/cm3 and 2.4 g/cm3 was measured at coupled high temperature high pressure conditions with a Rheometer Fann iX77 which is able to measure the rheology of drilling fluids with ultra-high densities at elevated temperatures and pressures. It was found that the apparent viscosity and the plastic viscosity of the four oil based drilling fluids gradually decrease with increase in temperature and gradually increase with increase in pressure. The yield points of the four drilling fluids first increase and then decrease with increase in temperature. When the temperature was increased to above about 160 ℃, the effect of high temperature on the rheology of the four drilling fluids was greatly weakened. In addition, a mathematical model involving temperature and pressure of the oil based drilling fluids was obtained based on the analyses of the rheological parameters measured of the four drilling fluids under coupled high temperature and high pressure. Error analysis results show that the model has a good fit to the measured parameters in the experiment of the drilling fluids with different densities, with the coefficient of determination R being greater than 0.96. It is thus determined that the mathematical model can be used to accurately predict the rheological characteristics of oil based drilling fluids under each coupled temperature and pressure condition.

-

表 1 4种密度油基钻井液的流变性能

ρ/

g·cm-3T老化/

℃PV/

mPa·sYP/

PaYP/PV/

Pa/( mPa·s)Gel/

Pa/Paφ6/φ3 ES/

V1.4 未老化 19.0 7.5 0.39 3.0/3.0 7/4 900 180 21.5 1.8 0.08 1.0/1.0 3/3 695 1.8 未老化 16.0 2.5 0.16 2.0/2.0 2/1 930 220 27.0 2.5 0.09 1.0/1.5 2/1 421 2.2 未老化 43.0 10.0 0.23 4.0/4.0 9/6 1241 220 58.5 5.0 0.09 3.0/7.0 4/3 494 2.4 未老化 40.0 11.0 0.28 4.0/4.0 10/9 1465 220 59.0 6.5 0.11 3.0/7.0 5/3 530 注:流变性均在65 ℃下测得 表 2 190 ℃各压力下油基钻井液的流变性能

P/MPa AV/mPa·s PV/mPa·s Gel/(Pa/Pa) 20 8 5.9 2.1 45 26.7 9.9 16.8 70 27.7 10.5 17.2 95 30.7 13.2 17.5 120 32.8 15.7 17.1 表 3 各密度钻井液表观黏度数学模型及误差分析

ρ/

g·cm−3AV0/

mPa·sγ1 γ2 γ3 R 1.4 23.3 9.72×10−5 −2.348×10−2 9.086×10−3 0.98 1.8 29.5 8.82×10−5 −2.251×10−2 8.532×10−3 0.96 2.2 63.5 9.483×10−5 −2.529×10−2 9.328×10−3 0.99 2.4 65.5 1.471×10−4 −3.085×10−2 1.042×10−2 0.98 注:测试温度65 ℃,测试压力0. 1 MPa 表 4 各密度油基钻井液塑性黏度数学模型及误差分析

ρ/

g·cm−3AV0/

mPa·sη1 η2 η3 R 1.4 21.5 1.402×10−4 −3.032×10−2 1.063×10−2 0.98 1.8 27.0 8.188×10−5 −2.358×10−2 9.132×10−3 0.99 2.2 58.5 7.177×10−5 −2.075×10−2 8.21×10−3 0.98 2.4 59.0 8.703×10−5 −2.254×10−2 9.243×10−3 0.97 注:测试温度65 ℃,测试压力0.1 MPa -

[1] ADEKOMAYA, OLUFEMI, OLAFUYI, OLALEKAN. Experimental study of the effect of temperature on the flow behaviour of oil-based muds in Niger delta formation[J]. International Journal of Oil Gas and Coal Technology, 2011, 4(4): 322-334. [2] 姜波. 分析高温高压井中温度和地层孔隙压力对钻井液密度的影响[J]. 当代化工研究,2018(5):76-77. doi: 10.3969/j.issn.1672-8114.2018.05.050JIANG Bo. Analysis on the influence of temperature and formation pore pressure on the density of drilling fluid in high temperature and high pressure wells[J]. Modern Chemical Research, 2018(5):76-77. doi: 10.3969/j.issn.1672-8114.2018.05.050 [3] HAMIDU MUWEWE. 高温高压对水基钻井液滤失性的影响[D]. 中国石油大学(华东), 2018.HAMIDU MUWEWE. Effect of high temperature and high pressure on filtration of water based muds[D]. China University of Petroleum(East China), 2018. [4] ROMMETVEIT R,RKEVOLL K S BJ,王景新. 温度和压力对钻井液流变性的影响[J]. 国外油田工程,1998(7):27-28.ROMMETVEIT R, RKEVOLL K S BJ, WANG Jingxing. The influence of temperature and pressure on the rheology of drilling fluid[J]. Foreign Oil Field Engineering, 1998(7):27-28. [5] 王敏生,易灿,徐加放. 高温高压对超深井钻井液密度的影响[J]. 石油钻采工艺,2007(5):85-87,124. doi: 10.3969/j.issn.1000-7393.2007.05.024WANG Minsheng, YI Can, XU Jiafang. The influence of high temperature and high pressure on the density of drilling fluid in ultra-deep wells[J]. Oil Drilling and Production Technology, 2007(5):85-87,124. doi: 10.3969/j.issn.1000-7393.2007.05.024 [6] 夏宏伟,谯青松. 测试温度对高密度水基钻井液流变性影响规律研究[J]. 中国石油和化工标准与质量,2012,32(1):103. doi: 10.3969/j.issn.1673-4076.2012.01.081XIA Hongwei, QIAO Qingsong. Study on the influence of test temperature on rheology of high-density water-based drilling fluid[J]. China Petroleum and Chemical Standards and Quality, 2012, 32(1):103. doi: 10.3969/j.issn.1673-4076.2012.01.081 [7] 王富华,王瑞和,王力,等. 深井水基钻井液流变性影响因素的实验研究[J]. 钻井液与完井液,2010(1):17-20. doi: 10.3969/j.issn.1001-5620.2010.01.006WANG Fuhua, WANG Ruihe, WANG Li, et al. Experimental research on the influencing factors of rheology of deep well water-based drilling fluid[J]. Drilling Fluid & Completion Fluid, 2010(1):17-20. doi: 10.3969/j.issn.1001-5620.2010.01.006 [8] WANG Fuhua, TAN Xuechao, WANG Ruihe, et al. High temperature and high pressure rheological properties of high-density water-based drilling fluids for deep wells[J]. Petroleum Science, 2012, 3(9):354-362. [9] MAO Hui, YANG Yan, ZHANG Hao. A critical review of the possible effects of physical and chemical properties of subcritical water on the performance of water-based drilling fluids designed for ultra-high temperature and ultra-high pressure drilling applications[J]. Journal of Petroleum Science and Engineering, 2020, 187: 12-21. [10] 白小东,蒲晓林. 国外保护储层的油基钻井完井液新技术研究与应用[J]. 精细石油化工进展,2005(12):12-14,17. doi: 10.3969/j.issn.1009-8348.2005.12.004BAI Xiaodong, PU Xiaolin. Research and application of new technology of oil-based drilling and completion fluid for reservoir protection abroad[J]. Advances in Fine Petrochemicals, 2005(12):12-14,17. doi: 10.3969/j.issn.1009-8348.2005.12.004 [11] 罗勇,张海山,王昌军,等. 抗高温油基钻井液的研究[J]. 石油天然气学报,2013,35(8):111-113. doi: 10.3969/j.issn.1000-9752.2013.08.025LUO Yong, ZHANG Haishan, WANG Changjun, et al. Research on high temperature resistant oil-based drilling fluid[J]. Journal of Oil and Gas Technology, 2013, 35(8):111-113. doi: 10.3969/j.issn.1000-9752.2013.08.025 [12] 李建成,杨鹏,关键,等. 新型全油基钻井液体系[J]. 石油勘探与开发,2014,41(4):490-496. doi: 10.11698/PED.2014.04.16LI Jiancheng, YANG Peng, GUAN Jian, et al. A new type of whole oil-based drilling fluid[J]. Petroleum Exploration and Development, 2014, 41(4):490-496. doi: 10.11698/PED.2014.04.16 [13] 鄢捷年,赵雄虎. 高温高压下油基钻井液的流变特性[J]. 石油学报,2003(3):104-109. doi: 10.3321/j.issn:0253-2697.2003.03.023YAN Jienian, ZHAO Xionghu. Rheological properties of oil-based drilling fluids under high temperature and high pressure[J]. Acta Petrolei Sinica, 2003(3):104-109. doi: 10.3321/j.issn:0253-2697.2003.03.023 [14] ZHAO Shengying, YAN Jienian, SHU Yong, et al. Rheological properties of oil-based drilling fluids at high temperature and high pressure[J]. Journal of Central South University of Technology, 2008, 15(1):457-461. [15] HERMOSO J, MARTINEZ-BOZA F, GALLEGOS C. Combined effect of pressure and temperature on the viscous behaviour of all-oil drilling fluids[J]. Oil & Gas Sicience and Technology, 2014, 69(7):1283-1296. [16] 纪健,袁华玉,李建,等. 深水钻井环境下低温高压对油基钻井液流变性的影响[J]. 内蒙古石油化工,2009,35(21):134-136.JI Jian, YUAN Huayu, LI Jian, et al. The effect of low temperature and high pressure on the rheology of oil-based drilling fluid in deep water drilling environment[J]. Inner Mongolia Petrochemical Industry, 2009, 35(21):134-136. -

下载:

下载: