Synthesis and Evaluation of A pH Stimulus-responsive High Temperature-resistant Reversible Emulsifier

-

摘要: 针对油基钻井液在应用后期存在的滤饼难以清除和含油钻屑不易处理难题,基于pH刺激响应型乳化剂对乳状液类型的智能调控机制,以1-溴代长链烷烃R和二乙醇胺为原料,通过霍夫曼烷基化反应合成了一种pH响应可逆转乳化剂RE-HT,并以其为核心研制了一种抗高温可逆乳化钻井液。红外光谱分析和乳状液酸/碱触变实验结果表明,合成产物分子结构中含有pH响应性叔胺基团,可在酸/碱刺激下于油包水型乳化剂和水包油型乳化剂之间灵活切换,性能优于其余3种pH响应可逆转乳化剂。热重分析和电稳定性测试结果显示,RE-HT在空气氛围下的初始热分解温度高达257 ℃,含5%RE-HT的基础乳状液在220 ℃高温热滚后破乳电压达1098 V,表明其具有良好的热稳定性和乳化性能。研制的可逆乳化钻井液基础性能良好,在15%饱和盐水侵和15%泥页岩钻屑侵后依然可保持良好的流变与滤失性能,破乳电压高于850 V。同时酸洗后的滤饼清除率达98.98%,岩屑含油量低于1%,EC50为2.05×105 mg/L,满足钻屑排放标准,在复杂深井钻井中有较好的应用前景。Abstract: The oil-based drilling fluid presences the problems of difficulty to remove filter cake and treat oily cuttings. Based on the intelligent regulation mechanism of the pH stimulus-responsive emulsifier on the emulsion type, a pH-responsive reversible emulsifier RE-HT was synthesized through Hoffman reaction with 1-Bromo long-chain Alkane R and Diethanolamine to solve these problems. And a reversible emulsion drilling fluid was developed by utilizing it as the core agent. The infrared spectroscopy analysis and emulsion acid/base thixotropy test showed that the synthesized product contains the pH-responsive tertiary amine group and can be flexibly switched between water-in-oil emulsifier and oil-in-water emulsifier under acid/alkali stimulation. Thermogravimetric analysis and electric stability tests showed that the initial thermal decomposition temperature of RE-HT in an air atmosphere is as high as 257 ℃, and the demulsification voltage of the basic emulsion with 5% RE-HT is 1098 V after aging at 220 ℃. This indicated that it has good thermal stability and emulsifying performance. The developed reversible emulsion drilling fluid has good basic performance and can tolerate high-temperature up to 200 ℃, saturated saltwater contamination up to 15%, and drilling cuttings contamination up to 15%. The filter cake removal rate after pickling is 98.98%, the oil content of cuttings after pickling is less than 1%, EC50 is 2.05×105 mg/L, meeting the cuttings discharge standard and exhibiting a good application prospect in complex deep wells drilling.p wells drilling.

-

0. 引言

油基钻井液具有出色的抗温性、润滑性、防塌抑制性和抗污染能力,是钻探深井超深井、大斜度井、页岩水平井以及复杂地层的重要手段 [1-2]。随着近年来油气勘探开发不断向超深层、深水、非常规领域拓展,进一步增加了油气钻探行业对油基钻井液的需求。但油基钻井液完钻后,黏附在井壁和套管表面的滤饼和油性钻井液难以清除,会改变固井界面的润湿性,降低水泥环与地层和套管之间的胶结强度,严重影响固井质量 [3]。同时,油基钻井液钻井过程中还会产生大量含油钻屑,未经处理的含油钻屑在堆放后,会造成土壤和水体污染 [4-5]。通过研发特殊的油基钻井液固井用冲洗液进行井下冲洗,以及采用固化、焚烧、溶剂萃取、热裂解和微生物降解等技术对含油钻屑进行处理,是弥补油基钻井液上述缺点的常用方法,但存在普适性差、操作复杂、效率不理想和处理成本高等问题 [6]。

可逆乳化钻井液是一种pH响应型“智能”钻井液,可在油包水乳化钻井液与水包油乳化钻井液之间按需切换,兼顾油基钻井液在钻井阶段的优异性能和水基钻井液在固完井阶段的易清洗优势,从根本上解决了油基钻井液在应用后期存在的滤饼难以清除、含油钻屑不易处理和处理成本高等问题[7-8]。pH刺激响应可逆转乳化剂是可逆乳化钻井液的核心处理剂,是赋予钻井液类型可智能调控机制的关键。但目前石油钻探行业内有关pH刺激响应可逆转乳化剂的报道甚少,更缺少适应于高温深井复杂地层钻探的可逆转乳化剂和可逆乳化钻井液。基于叔胺基团在酸/碱刺激下特殊的质子化与去质子化效应 [9-10],合成了一种pH响应可逆转乳化剂RE-HT,并对其分子结构和物理化学性质进行了表征,分析了pH刺激响应机制,评价了热稳定性与乳化性能,在此基础上研制了一种抗高温可逆乳化钻井液。

1. pH响应可逆转乳化剂合成与表征

1.1 实验材料与仪器

1-溴代长链烷烃R、二乙醇胺、无水碳酸钠、无水乙醇、氢氧化钠、无水乙酸、苏丹Ⅲ、碱性湖蓝BB、无水氯化钙、氯化钠、氧化钙,分析纯级;去离子水,实验室自制;5#白油、有机土130D、脂肪胺聚氧乙烯醚TAM-2、油烯基丙二胺Duomeen-O、油酸酰胺丙基二甲基叔胺PKO-O,工业级;RE-2000A旋转蒸发仪、Nicolet IS10傅里叶变换红外光谱仪、NETZSCH STA 449 热重分析仪、KRUSSS K100C-MK2表面张力测试仪、DWY-2 型电稳定性测定仪、GGS42-2A高温高压失水仪、ZNN-D6B电子六速黏度计、GW300-X变频高温滚子加热炉、YCHH0301型电振动筛、PHS-3G型pH计。

1.2 可逆转乳化剂RE-HT合成

采用霍夫曼烷基化反应制备可逆转乳化剂RE-HT [11]。称取0.21 mol二乙醇胺溶于100 mL无水乙醇中,搅拌均匀后将混合液转移至带有回流装置的250 mL三口烧瓶中,加入一定量的无水碳酸钠,搅拌升温至75 ℃。将0.2 mol 1-溴代长链烷烃R利用恒压滴液漏斗缓慢滴加到反应体系中(约30 min内加完),然后升温至90 ℃,恒温回流反应7 h。反应结束后过滤除去反应副产物溴化钠,再减压蒸馏除去溶剂,得浅白色液体。随后将获得的浅白色液体倒入5%NaOH溶液中,75 ℃下搅拌碱洗,静置分层,分液取上层油状液体。最后,将其在去离子水中重结晶5次,得纯度较高的N-烷基化二乙醇胺,命名为RE-HT。

1.3 红外光谱分析

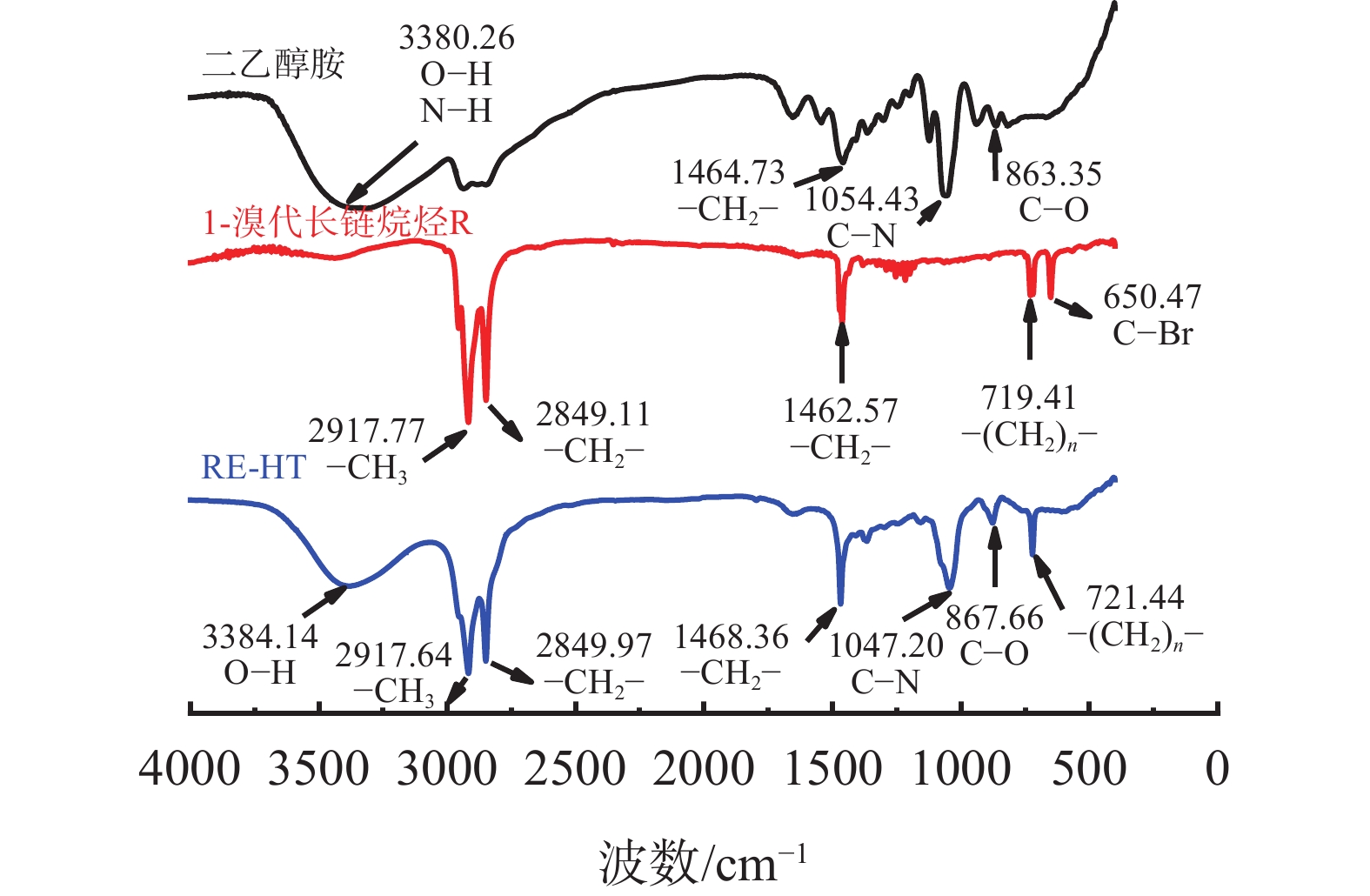

可逆转乳化剂RE-HT的红外光谱图如图1所示。位于3384.14 cm−1、1047.20 cm−1和867.66 cm−1处的特征吸收峰分别源自二乙醇胺中O—H、C—N和C—O键的伸缩振动。2917.64 cm−1和2849.97 cm−1分别为1-溴代长链烷烃R中甲基—CH3和亚甲基—CH2—的伸缩振动峰。1468.36 cm−1为二乙醇胺和1-溴代长链烷烃R中亚甲基—CH2—的弯曲振动峰。721.44 cm−1为1-溴代长链烷烃R中长链亚甲基 —(CH2)n—(n>4)的平面摇摆振动峰。因此,二乙醇胺与1-溴代长链烷烃R的烷基化取代反应进行成功,产物分子结构中含有pH响应性叔胺基团。另外,3300~3500 cm−1波段峰谷的变窄以及650 cm−1附近峰的消失,说明产物中不含N—H和C—Br键,表明合成产物已被充分提纯。

1.4 理化性能与生物毒性测试

通过核磁共振法、表面张力法和盐酸滴定法测定了乳化剂RE-HT的HLB值、CMC、γcmc和胺值 [12-14],并依据标准SY/T 6788—2010《水溶性油田化学剂环境保护技术评价方法》进行发光细菌急性毒性EC50测试,以评估RE-HT的环境可接受性。由表1可知,RE-HT的HLB值低于6,CMC值和γcmc值较小,胺值较高,是一种较为理想的油包水乳化钻井液用乳化剂。另外,RE-HT的EC50为5.68×105 mg/L,远大于标准值20 000 mg/L,无生物毒性,能满足钻井现场对钻井液处理剂环保性能的要求。

表 1 乳化剂RE-HT理化性能与生物毒性ρ/

g/cm3HLB CMC/

mol/Lγcmc/

mN/m胺值/

mgKOH/gEC50/

mg/L0.907 5.82 2.79×10−4 22.4 157 5.68×105 注:生物毒性检测中RE-HT浓度为5% 2. 乳化剂RE-HT的pH响应特性

2.1 酸/碱刺激可逆乳化特性

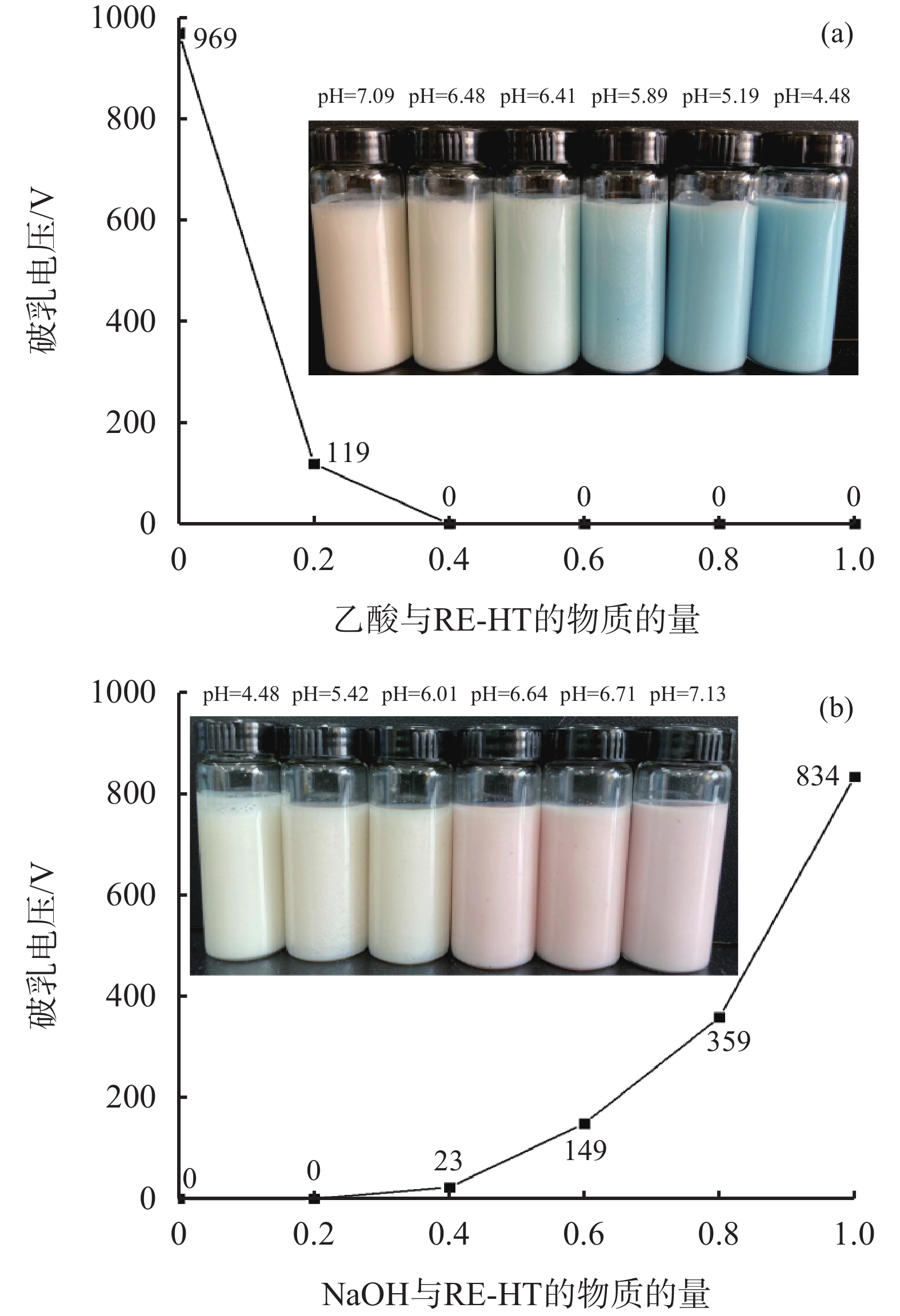

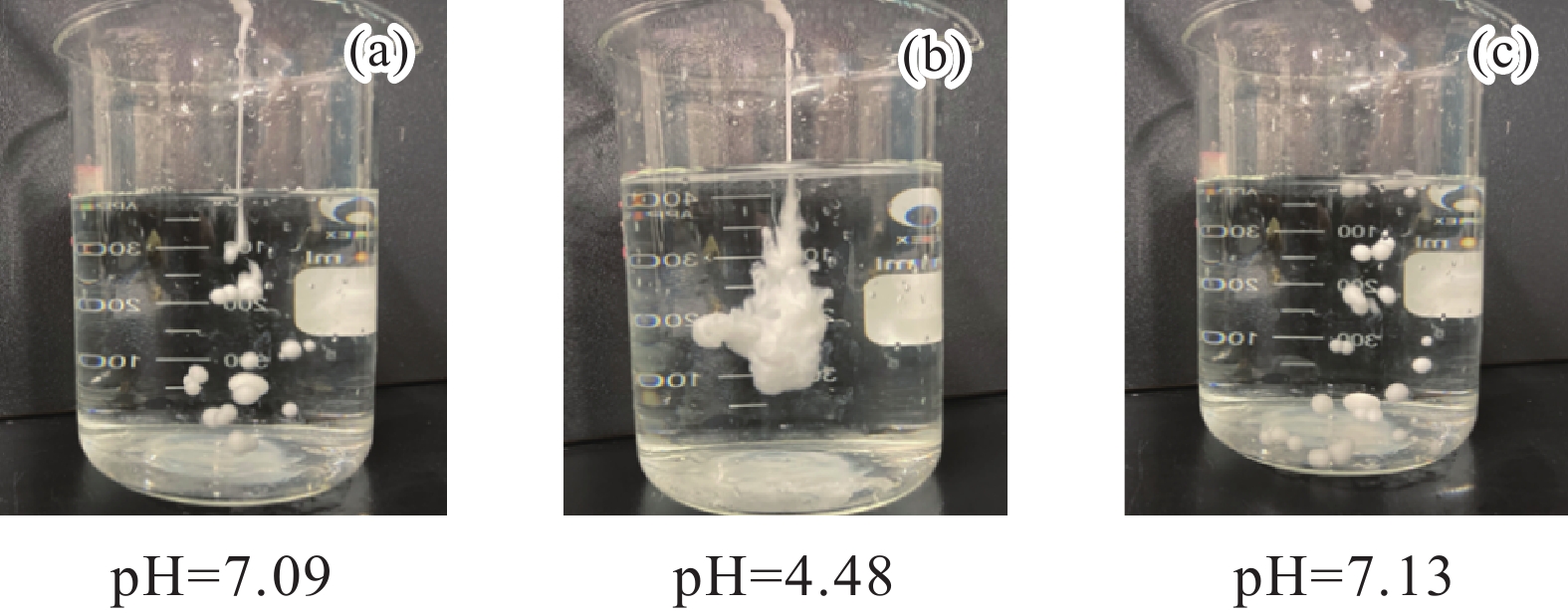

通过乳状液酸/碱触变实验考察了RE-HT的可逆乳化特性。乳状液配方:150 mL 5#白油+5%RE-HT +150 mL 25%CaCl2溶液。以50%乙酸和20%NaOH作为乳状液pH值调节剂,油溶性染料苏丹Ⅲ和水溶性染料碱性湖蓝BB作为外相指示剂。如图2(a)所示,随着pH值降低,乳状液破乳电压逐渐减小,且逐渐能被微量的碱性湖蓝BB着色。当pH值为4.48,乳状液破乳电压降低至0 V,颜色彻底变为淡蓝色,乳状液由非水溶性转变为水溶性(图2(b)),表明此时乳状液的外相由油相转变为水相,类型转变为水包油型。取pH值为4.48时的乳状液进行碱触回,如图2(b)所示,随着pH值增加,乳状液破乳电压逐渐升高,且逐渐能被微量的苏丹Ⅲ着色,当pH值为7.13时,乳状液破乳电压增加至834 V,颜色彻底变为粉红色,乳状液逆转为非水溶性(图2(c)),表明乳状液外相由水相逆转为油相,乳状液类型逆转为油包水型。因此,RE-HT具备酸/碱刺激可逆乳化特性,可在油包水型乳化剂与水包油型乳化剂之间灵活切换,不同pH值乳状液的水溶性见图3。

2.2 刺激响应机理

原始状态下,RE-HT是一种非离子型乳化剂,进入油水两相体系后,疏水端(长链饱和烷烃CnH2n+1)插入油相,亲水头基(N(CH2CH2OH)2)伸向水相与水分子形成氢键吸附,从而使其自身处于油水界面处,形成定向吸附层。由于其HLB值低于6,亲油性大于亲水性,根据双重膜理论和几何排列理论,此时疏水端截面积大于亲水头基截面积,油水界面膜凸向油相,从而形成油包水乳状液。当乳状液受到乙酸刺激时,RE-HT亲水头基中的叔胺基团会接受乙酸给予的质子H+,发生质子化 [9, 10, 15],响应为阳离子型乳化剂,HLB值增加至10以上,亲水性大于亲油性,且由于亲水头基之间存在静电斥力,使得乳化剂膜的水化半径大大增加。另一方面,在静电相互作用下,质子化后的RE-HT可与乙酸(CH3COO−)形成超分子组装 [16],使得亲水头基截面积进一步增加,最终导致油水界面膜凸向水相,从而形成水包油乳状液。当乳状液再次受到碱刺激时,RE-HT的叔胺基团发生去质子化效应,响应为非离子型乳化剂,头基之间静电斥力消失,乳化剂与乙酸形成的超分子组装被破坏,亲水头基截面积减小,乳化剂HLB值恢复至6以下,界面膜再次凸向油相,逆转至油包水乳状液。

3. 可逆转乳化剂RE-HT的性能评价

3.1 热稳定性

在井底高温环境下,乳化剂分子易被高温分解,从而影响自身乳化性能,严重时将失去乳化能力。采用热重分析仪评价了可逆转乳化剂RE-HT在空气氛围下的热稳定性,并将测试结果与TAM-2、Duomeen-O和PKO-O等3种已报道的pH响应可逆转乳化剂进行对比。由图4可知,RE-HT的起始热分解温度和最大热分解温度均为最高,分别高达257 ℃和320 ℃,且在温度为260 ℃时,RE-HT的质量保留率高达94.33%,表明RE-HT具有良好的热稳定性,能妥善应对大多数钻井高温环境。

3.2 电稳定性

通过测定在不同老化温度下热滚16 h后的基础乳状液的电稳定性评价了可逆转乳化剂RE-HT的乳化性能,并将其与TAM-2、Duomeen-O和PKO-O进行对比。基础乳状液配方为:150 mL 5#白油+5%乳化剂+150 mL 25%CaCl2溶液。由图5可知,随着老化温度的逐渐升高,采用TAM-2、Duomeen-O和PKO-O配制的基础乳状液的破乳电压均表现出逐渐降低的趋势,当老化温度为220 ℃时,破乳电压分别仅为344、92和64 V,表明高温严重影响了这3种乳化剂的乳化稳定性。然而,RE-HT表现出随着老化温度升高,破乳电压略微增加的趋势,在老化温度为220 ℃时,破乳电压高达1098 V,表明乳化剂RE-HT具有出色的抗高温乳化性能。这是由于RE-HT疏水碳链长度与油相烷烃碳链长度接近,且亲水头基中含有强吸附基团胺基和羟基,使其可以通过氢键作用牢靠地吸附在油水界面处,不易在高温下解吸附。同时,由于相邻羟基之间存在氢键相互作用,乳化剂分子之间在高温下不易彼此分离,进而能紧密排列在油水界面处,形成高强度界面膜,赋予乳状液良好的稳定性 [17]。另一方面,RE-HT自身具有良好的热稳定性,不易发生高温氧化分解,进一步保证了其在高温条件下优异的乳化稳定性。

3.3 抗高温可逆乳化钻井液性能

3.3.1 体系配方与基础性能

以pH响应可逆转乳化剂RE-HT为核心,筛选有机土、封堵剂和润湿剂,并进行加量优选,研制出一套可逆乳化钻井液,其配方如下。

150 mL 5#白油+5%RE-HT+1.5%有机土130D+0.5%CaO+2%微纳米封堵剂OSD-1+1.5%润湿剂+150 mL 25%CaCl2溶液+重晶石,密度为1.40 g/cm3

钻井液在180 ℃下老化16 h前后的基础性能见表2。由表2可知,该钻井液在老化前后均具有合理的黏度与切力,高温高压滤失量低于5 mL,破乳电压达1000 V以上,且能在酸刺激下转变为水包油乳化钻井液,在碱刺激下逆转回油包水乳化钻井液。另外,酸触转相后,各项性能均处于可接受的合理范围内,碱触回转后,黏度、切力、滤失量和电稳定性与酸触转相前相比波动较小。因此,该钻井液各项基础性能良好,具有可逆乳化特性,酸/碱触变后可重复再利用,能满足实际钻井施工需求。

表 2 基于RE-HT的可逆乳化钻井液体系的基础性能测试

条件钻井液

类型AV/

mPa∙sPV/

mPa∙sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

VpH 热滚前 油包水 43.5 36 7.67 3.0/3.5 1030 8.47 热滚后 油包水 55.0 41 14.31 5.5/6.5 4.4 1092 8.43 酸触转相 水包油 61.5 46 15.84 3.5/5.5 11.5 0 6.58 碱触回转 油包水 59.0 44 15.33 5.5/7.0 4.6 913 8.52 注:老化条件为180 ℃×16 h;流变与破乳电压测试温度为50 ℃;FLHTHP测试条件为180 ℃、3.5 MPa;酸触用酸为50% 乙酸水溶液;碱触用碱为20%NaOH水溶液 3.3.2 抗温性能

进一步考察了基于pH响应可逆转乳化剂RE-HT的可逆乳化钻井液的抗温性能,结果见表3。由表3可知,该钻井液体系在180 ℃下老化72 h后依然具有良好的流变性,高温高压滤失量仅为5.6 mL,破乳电压达1017 V;当老化温度增加至200 ℃时,钻井液黏度切力略有降低,滤失量略有增加,但各项基础性能依然保持良好,破乳电压高达987 V。当老化温度继续增加至220 ℃时,钻井液破乳电压依然高达937 V,表明其乳化稳定性依然保持良好,但黏度切力明显下降,高温高压滤失量明显增加,这是由于钻井液中有机土、润湿剂和封堵剂在超高温下失效所致。该钻井液良好的抗高温乳化稳定性与乳化剂热重分析和单剂性能评价结果表现出一致。以上分析表明,该钻井液体系抗温可达200 ℃。

表 3 基于RE-HT的可逆乳化钻井液体系的抗温性能T老化/

℃t老化/

hAV/

mPa∙sPV/

mPa∙sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V180 16 55.0 41 14.31 5.5/6.5 4.4 1092 48 49.0 37 12.26 5.0/6.0 6.0 1073 72 46.5 36 10.73 4.0/5.0 5.6 1017 200 16 52.0 40 12.26 5.0/6.0 8.4 987 220 16 46.0 38 8.18 3.0/3.5 17.3 937 注:流变与破乳电压测试温度为50 ℃;FLHTHP测试条件为180 ℃、3.5 MPa 3.3.3 抗污染性能

向可逆乳化钻井液中加入不同质量体积比的饱和NaCl盐水和泥页岩钻屑,并在180 ℃下热滚16 h,以评价可逆乳化钻井液的抗污染能力。由表4可知,随着饱和NaCl盐水的侵入,钻井液切力略有升高,破乳电压小幅下降,但各项性能依然保持良好,高温高压滤失量始终小于6 mL,破乳电压始终大于850 V。这是由于RE-HT是一种非离子型乳化剂,具有较强的电解质耐受性,其所形成的乳状液的界面膜强度对盐水中Na+离子的攻击不敏感,进而赋予了可逆乳化钻井液出色的抗盐污染能力。泥页岩钻屑侵入对该钻井液体系各项基础性能基本无影响,表明该体系具有良好的抑制泥页岩分散的能力。因此,该钻井液体系能抗15%饱和盐水侵和15%泥页岩钻屑侵。

表 4 RE-HT配制的可逆乳化钻井液体系的抗污染性能污染

条件测试

条件AV/

mPa∙sPV/

mPa∙sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V5%饱和

盐水热滚前 50.5 36 14.82 4.5/6.0 1072 热滚后 58.5 43 15.84 5.0/6.0 4.6 962 10%饱和

盐水热滚前 52.0 36 16.35 5.0/6.5 965 热滚后 60.5 44 16.86 5.5/6.5 5.6 859 15%饱和

盐水热滚前 61.0 44 17.37 6.0/7.0 950 热滚后 67.5 48 19.93 6.5/8.0 5.4 883 10%泥页

岩钻屑热滚前 45.0 37 8.18 3.0/3.5 1045 热滚后 56.0 41 15.33 5.5/6.0 4.3 1078 15%泥页

岩钻屑热滚前 46.5 37 9.71 3.0/3.5 1145 热滚后 57.0 41 16.35 5.5/6.5 4.7 1176 注:老化条件为180 ℃×16 h;流变与破乳电压测试温度为50 ℃;FLHTHP测试条件为180 ℃、3.5 MPa 3.3.4 滤饼清除特性

测试了可逆乳化钻井液的滤饼清除率,并将测试结果与常规油基钻井液对比。具体步骤为:将柱状泥页岩岩心(3 cm高× 2.5 cm 直径,采自四川露头泥页岩)置于GGS42-2A型高温高压滤失仪的不锈钢钻井液杯中,填入钻井液样品至钻井液杯刻度线处,在180 ℃、3.5 MPa下进行高温高压滤失量测试,测试时间为30 min,此过程中岩心表面将会有滤饼形成。测试完毕后,将带有油性滤饼的岩心取出称重,然后将其固定在搅拌杆上,在200 r/min的转速下于2%乙酸水溶液中清洗10 min。清洗完毕后,再次烘干称重,通过公式

$ R_{\rm r}=\dfrac{{m}_{1}-{m}_{2}}{{m}_{1}-{m}_{0}} $ ×100%计算滤饼清除率Rr。式中,m0为岩心原始质量;m1为带有滤饼的岩心质量;m2为清洗后的岩心质量。常规油基钻井液和可逆乳化钻井液的滤饼清除率见表5。测试结果显示,可逆乳化钻井液的滤饼清除率高达98.98%,清洗后的岩心表面基本无滤饼黏附,滤饼清除效果明显优于常规油基钻井液。这是由于滤饼中存在pH响应乳化剂RE-HT,其可在乙酸刺激下转变为水包油型乳化剂,对滤饼中的难溶或不溶于水的有机物起到“增溶”作用,使得黏附于岩心表面的滤饼转变为水易溶状态,在水流冲击下崩解、脱附 [4]。

表 5 常规油基钻井液和可逆乳化钻井液滤饼清除率对比钻井液样品 m0/g m1/g m2/g Rr/% 常规油基钻井液 43.76 45.39 44.34 64.42 可逆乳化钻井液 42.20 45.14 42.23 98.98 注:常规油基钻井液配方:255 mL 5#白油+3%主乳化剂+2% 辅乳化剂+3%有机土130D+3%CaO+2%微纳米封堵剂OSD-1+1.5%润湿剂+45 mL 25%CaCl2溶液+重晶石 3.3.5 含油钻屑处理特性

取一定质量6~10目泥页岩岩屑(取自四川省某页岩气开发区)置于钻井液中,在180 ℃下热滚72 h,利用YCHH0301型电振动筛(200目)分离回收岩屑,以模拟含油钻屑。以二氯甲烷为萃取剂,采用索氏提取法对含油钻屑进行萃取,萃取条件为40 ℃、72 h。萃取结束后,利用RE-2000A旋转蒸发仪将二氯甲烷蒸发,得残余油,计算含油钻屑的含油量 [18]。然后,取一定质量的含油钻屑放置于玻璃烧杯中,加入2%乙酸水溶液,转速为200 r/min的磁力搅拌下清洗2 min,将清洗液替换为蒸馏水再次清洗1 min,70 ℃下干燥24 h后再次测量岩屑含油量,并将其粉碎测试生物毒性EC50。由表6可知,可逆乳化钻井液所产生的含油钻屑在清洗后,含油量由12.13%降低至0,EC50为2.05×105 mg/L,符合标准GB 4914—2008《海洋石油勘探开发污染物排放浓度限值》中非水基钻井液一级海域钻屑排放标准。常规油基钻井液所产生的含油钻屑在清洗后的含油量依然达6.42%,且EC50明显低于清洗后的可逆乳化钻井液钻屑,表明其对环境的影响程度高于可逆乳化钻井液。这是由于常规油基钻井液中的乳化剂不具备pH响应特性,无法在乙酸刺激下转变为水包油型乳化剂,因而不能将黏附于钻屑上的油性钻井液转变为水易溶状态。

表 6 常规油基和可逆乳化钻井液含油钻屑处理效果对比检测项目 常规油基

钻井液岩屑可逆乳化

钻井液岩屑容许值 酸洗前 酸洗后 酸洗前 酸洗后 一级海域 含油量/% 11.38 6.42 12.13 0 <1 EC50/(mg·L−1) 3.74×104 2.05×105 >3.0×104 注:常规油基钻井液配方:255 mL 5#白油+3%主乳化剂+2%辅乳化剂+3%有机土130D+3%CaO+2%微纳米封堵剂OSD-1+1.5%润湿剂+45 mL 25%CaCl2溶液+重晶石 4. 结论

1. 以1-溴代长链烷烃R和二乙醇胺为原料,通过霍夫曼烷基化反应合成了pH响应可逆转乳化剂RE-HT。乳化剂RE-HT具备pH响应特性,能在酸/碱刺激下于油包水型乳化剂与水包油型乳化剂之间灵活切换,且具有良好的热稳定性与抗高温乳化性能,性能优于其余3种pH响应可逆转乳化剂,单剂抗温能力达220 ℃以上。

2. 基于RE-HT研制的可逆乳化钻井液各项基础性能良好,抗温达200 ℃,在15%饱和盐水侵和15%泥页岩钻屑侵后依然可保持良好的流变与滤失性能,破乳电压高于850 V。同时,与常规油基钻井液相比,该可逆乳化钻井液具有滤饼易清除特性,能实现含油钻屑无害化处理,在复杂深井钻井中具有良好的应用前景。

-

表 1 乳化剂RE-HT理化性能与生物毒性

ρ/

g/cm3HLB CMC/

mol/Lγcmc/

mN/m胺值/

mgKOH/gEC50/

mg/L0.907 5.82 2.79×10−4 22.4 157 5.68×105 注:生物毒性检测中RE-HT浓度为5% 表 2 基于RE-HT的可逆乳化钻井液体系的基础性能

测试

条件钻井液

类型AV/

mPa∙sPV/

mPa∙sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

VpH 热滚前 油包水 43.5 36 7.67 3.0/3.5 1030 8.47 热滚后 油包水 55.0 41 14.31 5.5/6.5 4.4 1092 8.43 酸触转相 水包油 61.5 46 15.84 3.5/5.5 11.5 0 6.58 碱触回转 油包水 59.0 44 15.33 5.5/7.0 4.6 913 8.52 注:老化条件为180 ℃×16 h;流变与破乳电压测试温度为50 ℃;FLHTHP测试条件为180 ℃、3.5 MPa;酸触用酸为50% 乙酸水溶液;碱触用碱为20%NaOH水溶液 表 3 基于RE-HT的可逆乳化钻井液体系的抗温性能

T老化/

℃t老化/

hAV/

mPa∙sPV/

mPa∙sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V180 16 55.0 41 14.31 5.5/6.5 4.4 1092 48 49.0 37 12.26 5.0/6.0 6.0 1073 72 46.5 36 10.73 4.0/5.0 5.6 1017 200 16 52.0 40 12.26 5.0/6.0 8.4 987 220 16 46.0 38 8.18 3.0/3.5 17.3 937 注:流变与破乳电压测试温度为50 ℃;FLHTHP测试条件为180 ℃、3.5 MPa 表 4 RE-HT配制的可逆乳化钻井液体系的抗污染性能

污染

条件测试

条件AV/

mPa∙sPV/

mPa∙sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V5%饱和

盐水热滚前 50.5 36 14.82 4.5/6.0 1072 热滚后 58.5 43 15.84 5.0/6.0 4.6 962 10%饱和

盐水热滚前 52.0 36 16.35 5.0/6.5 965 热滚后 60.5 44 16.86 5.5/6.5 5.6 859 15%饱和

盐水热滚前 61.0 44 17.37 6.0/7.0 950 热滚后 67.5 48 19.93 6.5/8.0 5.4 883 10%泥页

岩钻屑热滚前 45.0 37 8.18 3.0/3.5 1045 热滚后 56.0 41 15.33 5.5/6.0 4.3 1078 15%泥页

岩钻屑热滚前 46.5 37 9.71 3.0/3.5 1145 热滚后 57.0 41 16.35 5.5/6.5 4.7 1176 注:老化条件为180 ℃×16 h;流变与破乳电压测试温度为50 ℃;FLHTHP测试条件为180 ℃、3.5 MPa 表 5 常规油基钻井液和可逆乳化钻井液滤饼清除率对比

钻井液样品 m0/g m1/g m2/g Rr/% 常规油基钻井液 43.76 45.39 44.34 64.42 可逆乳化钻井液 42.20 45.14 42.23 98.98 注:常规油基钻井液配方:255 mL 5#白油+3%主乳化剂+2% 辅乳化剂+3%有机土130D+3%CaO+2%微纳米封堵剂OSD-1+1.5%润湿剂+45 mL 25%CaCl2溶液+重晶石 表 6 常规油基和可逆乳化钻井液含油钻屑处理效果对比

检测项目 常规油基

钻井液岩屑可逆乳化

钻井液岩屑容许值 酸洗前 酸洗后 酸洗前 酸洗后 一级海域 含油量/% 11.38 6.42 12.13 0 <1 EC50/(mg·L−1) 3.74×104 2.05×105 >3.0×104 注:常规油基钻井液配方:255 mL 5#白油+3%主乳化剂+2%辅乳化剂+3%有机土130D+3%CaO+2%微纳米封堵剂OSD-1+1.5%润湿剂+45 mL 25%CaCl2溶液+重晶石 -

[1] 覃勇,蒋官澄,邓正强,等. 抗高温油基钻井液主乳化剂的合成与评价[J]. 钻井液与完井液,2016,33(1):6-10.QIN Yong, JIANG Guancheng, DENG Zhengqiang, et al. Synthesis and evaluation of a primary emulsifier for high temperature oil base drilling fluidr[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):6-10. [2] 王星媛,陆灯云,吴正良. 抗220 ℃高密度油基钻井液的研究与应用[J]. 钻井液与完井液,2020,37(5):550-554,560.WANG Xingyuan, LU Dengyun, WU Zhengliang. Study and application of a high density oil base drilling fluid with high temperature resistance of 220 ℃[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):550-554,560. [3] 霍锦华,张瑞,杨磊,等. CTAB诱导膨润土乳液转相机理及其在可逆乳化油基钻井液中的应用[J]. 石油学报,2018,39(1):122-128. doi: 10.7623/syxb201801012HUO Jinhua, ZHANG Rui, YANG Lei, et al. Phase transition mechanism of CTAB inducing bentonite emulsion and its application in reversible emulsification oil-based drilling fluids[J]. Acta Petrolei Sinica, 2018, 39(1):122-128. doi: 10.7623/syxb201801012 [4] 黄贤斌,蒋官澄,万伟,等. 含油钻屑微乳状液除油剂的研制及机理[J]. 石油学报,2016,37(6):815-820.HUANG Xianbin, JIANG Guancheng, WAN Wei, et al. Preparation and mechanism of microemulsion deoiler for oily cuttings[J]. Acta Petrolei Sinica, 2016, 37(6):815-820. [5] 黄维巍,周泽军,何勇,等. 页岩气开发油基钻屑真空热解资源化处理[J]. 环境工程学,2017,11(8):4783-4788.HUANG Weiwei, ZHOU Zejun, HE Yong, et al. Resources utilization of oil-based drilling cuttings vacuum pyrolysising in shale gas developing[J]. Chinese Journal of Environmental Engineering, 2017, 11(8):4783-4788. [6] 黄志强,徐子扬,权银虎,等. 锤磨热解析处理油基钻井液钻屑的效果评价[J]. 天然气工业,2018,38(8):83-90. doi: 10.3787/j.issn.1000-0976.2018.08.012HUANG Zhiqiang, XU Ziyan, QUAN Yinhu, et al. Effect evaluation of hammer-milling thermal desorption technology on oil-based drilling fluid cuttings[J]. Natural Gas Industry, 2018, 38(8):83-90. doi: 10.3787/j.issn.1000-0976.2018.08.012 [7] PATEL, A D. Reversible invert emulsion drilling fluids: a quantum leap in technology[J]. SPE Drill & Completion, 1999, 14(4):274-279. [8] 任妍君,蒋官澄,张弘,等. 基于乳状液转相技术的钻井液新体系室内研究[J]. 石油钻探技术,2013,41(4):87-91. doi: 10.3969/j.issn.1001-0890.2013.04.019REN Yanjun, JIANG Guancheng, ZHANG Hong, et al. Laboratory study of a novel drilling fluid based on emulsion phase diversion technology[J]. Petroleum Drilling Techniques, 2013, 41(4):87-91. doi: 10.3969/j.issn.1001-0890.2013.04.019 [9] 武文涛,张永民,刘雪锋. 叔胺基CO2开关表面活性剂的合成及性能研究[J]. 日用化学工业,2016,46(5):251-256.WU Wentao, ZHANG Yongmin, LIU Xuefeng. Synthesis and performance of tertiary amine-based CO2 switchable surfactant[J]. China Surfactant Detergent & Cosmetics, 2016, 46(5):251-256. [10] REN Yanjun, JIANG Guancheng, ZHANG Zhihang, et al. Phase inversion pathways of emulsions stabilized by ethoxylated alkylamine surfactants[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2014, 452: 95-102. [11] 刘满辉. 多甲氧基黄酮羟乙基和胺烷基衍生物的合成研究[D]. 长沙: 湖南大学, 2018.LIU Manhui. Study on the synthesis of polymethoxy flavonoid hydroxyethyl and amino alkyl derivatives[D]. Changsha: Hunan University, 2018. [12] 周家华,崔英德. 表面活性剂HLB值的分析测定与计算Ⅰ. HLB值的分析测定[J]. 精细石油化工,2001(2):11-14. doi: 10.3969/j.issn.1003-9384.2001.02.004ZHOU Jiahua, CUI Yingde. Analysis, determination, and calculation of HLB value of surfactant Ⅰ. Analysis and determination of HLB value[J]. Speciality Petrochemicals, 2001(2):11-14. doi: 10.3969/j.issn.1003-9384.2001.02.004 [13] 刘明华,胡小燕,国安平,等. 油基钻井液用抗高温乳化剂的合成及性能[J]. 精细石油化工进展,2017,18(4):9-12. doi: 10.3969/j.issn.1009-8348.2017.04.003LIU Minghua, HU Xiaoyan, GUO Anping, et al. Synthesis and performance of anti-high temperature emulsifier for oil-based drilling fluid[J]. Speciality Petrochemicals, 2017, 18(4):9-12. doi: 10.3969/j.issn.1009-8348.2017.04.003 [14] 邓小刚,罗飞,马丽华,等. 磺基甜菜碱的合成及其在水包油乳化钻井液中的应用[J]. 钻井液与完井液,2017,34(3):33-38. doi: 10.3969/j.issn.1001-5620.2017.03.006DENG Xiaogang, LUO Fei, MA Lihua, et al. Sulfonated betaine: synthesis and application in oil-in-water emulsions[J]. Drilling Fluid & Completion Fluid, 2017, 34(3):33-38. doi: 10.3969/j.issn.1001-5620.2017.03.006 [15] WANG Fang, PI Jing, LIU Jingyu, et al. Highly-efficient separation of oil and water enabled by a silica nanoparticle coating with pH-triggered tunable surface wettability[J]. Journal of Colloid and Interface Science, 2019, 557:65-75. doi: 10.1016/j.jcis.2019.08.114 [16] LI Hao, CENGIZ Yegin, CHENG Chen, et al. pH-Responsive emulsions with supramolecularly assembled Shells[J]. Industrial & Engineering Chemistry Research, 2018, 57(28):9231-9239. [17] 杜坤. 油基钻井液新型高效乳化剂的研制与评价[J]. 钻井液与完井液,2020,37(5):555-560.DU Kun. Development and evaluation of a new high efficiency emulsifier for oil base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):555-560. [18] 周浩. 含油钻屑的热解特性研究[D]. 南京: 东南大学, 2017.ZHOU Hao. Study on the pyrolysis characteristics of oily cuttings[D]. Nanjing: Southeast University, 2017. 期刊类型引用(8)

1. 王军平,曹青天. 油气钻采用pH响应材料的研究与应用进展. 油田化学. 2025(01): 159-166+173 .  百度学术

百度学术2. 刘昊. 固井清洗剂DQQX-2及其冲洗液体系的研制与应用. 钻井液与完井液. 2024(04): 531-536 .  本站查看

本站查看3. 赵庆哲,蓝强,郑成胜. 油基钻井液用乳化剂的研究现状及发展趋势. 山东化工. 2023(07): 88-90 .  百度学术

百度学术4. 杨剑,刘飞,王学武,代晓东,王立强,杨诺,刘畅,王阳,姚志豪,孙娜. 配液水对可逆乳状液体系性能影响规律研究. 山东化工. 2023(08): 44-46 .  百度学术

百度学术5. 孙金声,蒋官澄. 钻井工程“血液”——钻完井液技术的发展现状与趋势. 前瞻科技. 2023(02): 62-74 .  百度学术

百度学术6. 孙金声,蒋官澄,贺垠博,史赫,杜明亮,董腾飞,杨丽丽. 油基钻井液面临的技术难题与挑战. 中国石油大学学报(自然科学版). 2023(05): 76-89 .  百度学术

百度学术7. 姚海雷,刘飞,王学武,代晓东,张程翔,杨剑,孟嘉孟,刘畅,王阳. 可逆乳状液多次重复可逆转化能力研究. 山东化工. 2022(14): 56-58 .  百度学术

百度学术8. 杨俊,蒋官澄,王国帅,贺垠博,杨丽丽,袁学强. 自交联型油基钻井液降滤失剂的研制与评价. 钻井液与完井液. 2022(06): 685-691 .  本站查看

本站查看其他类型引用(1)

-

下载:

下载:

下载:

下载:

百度学术

百度学术