A Drilling Fluid Which Inhibits Formation of Natural Gas Hydrate at Low Temperatures in Offshore Drilling

-

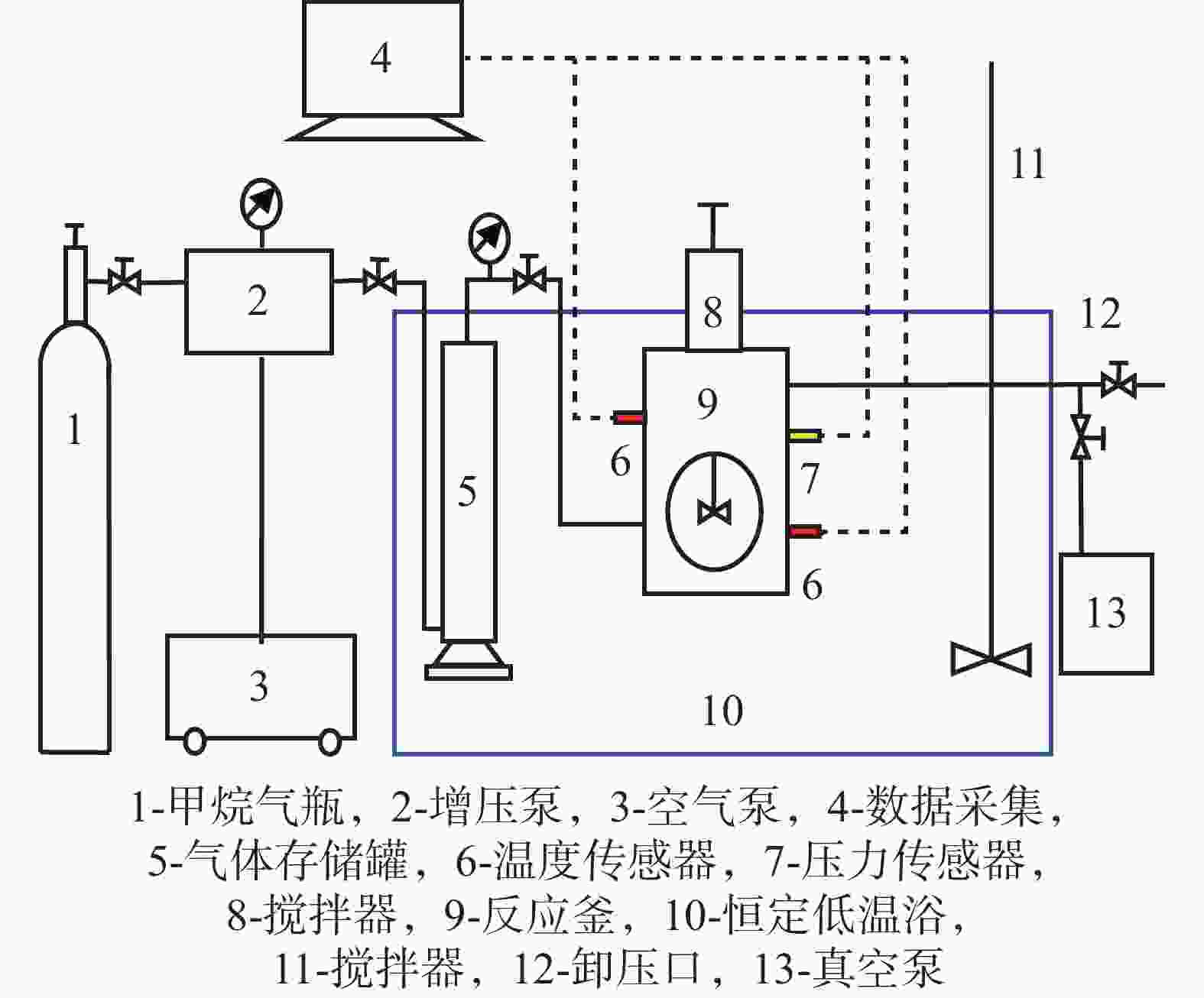

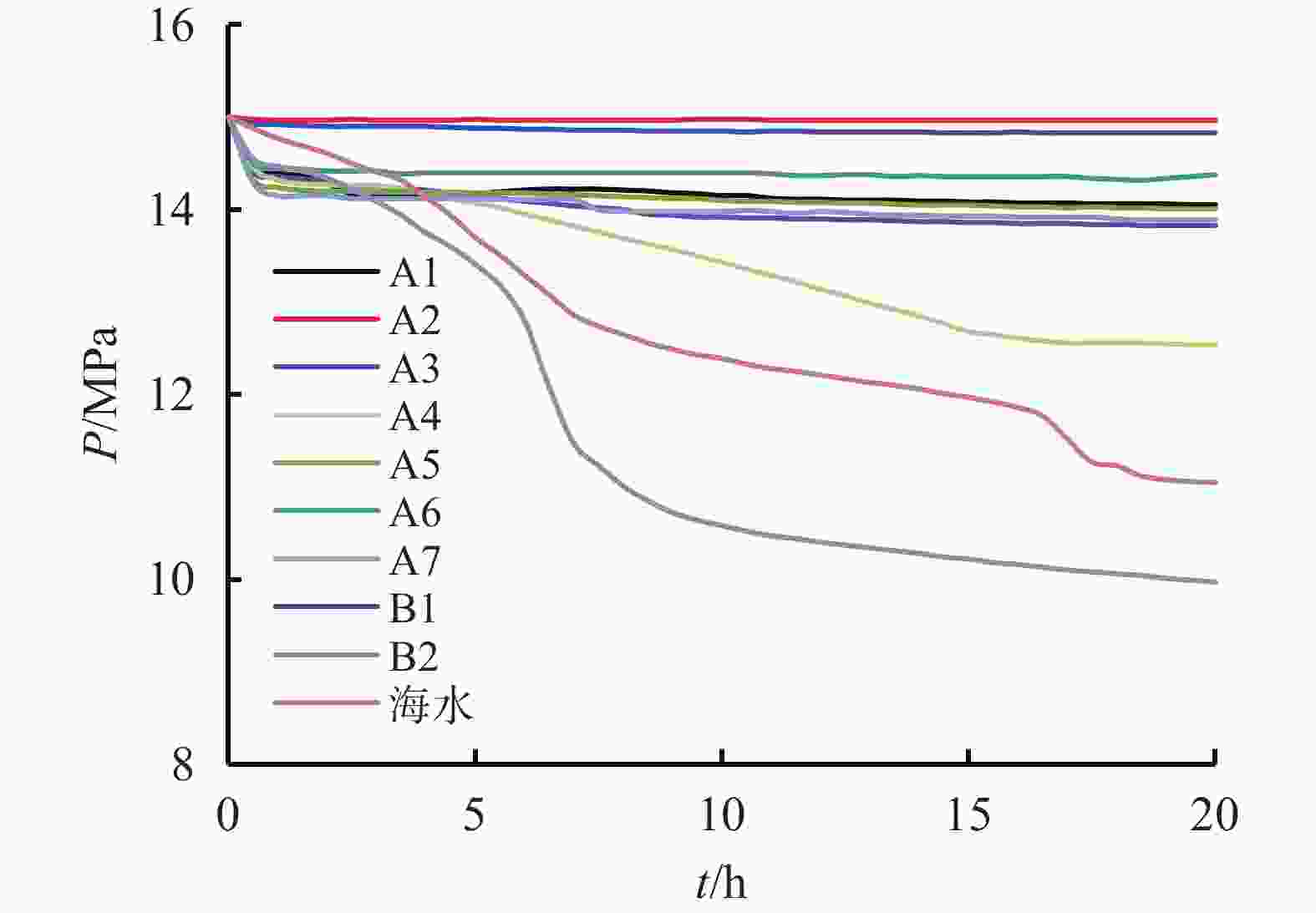

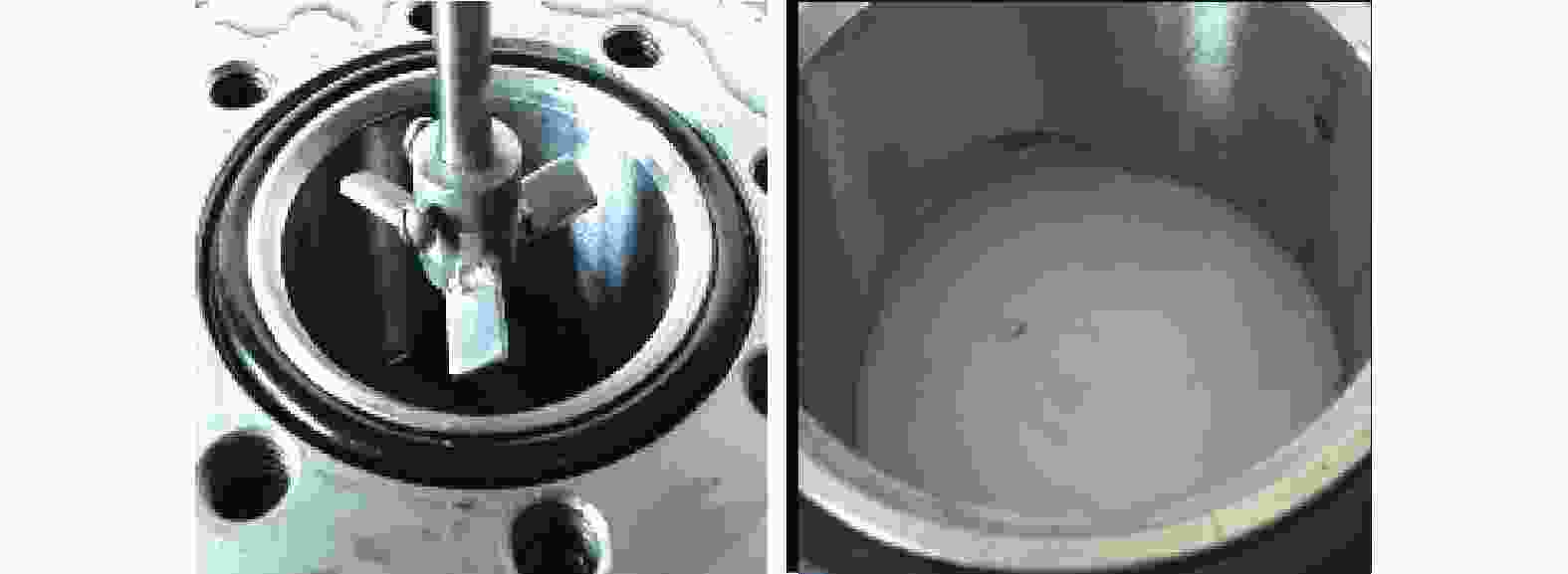

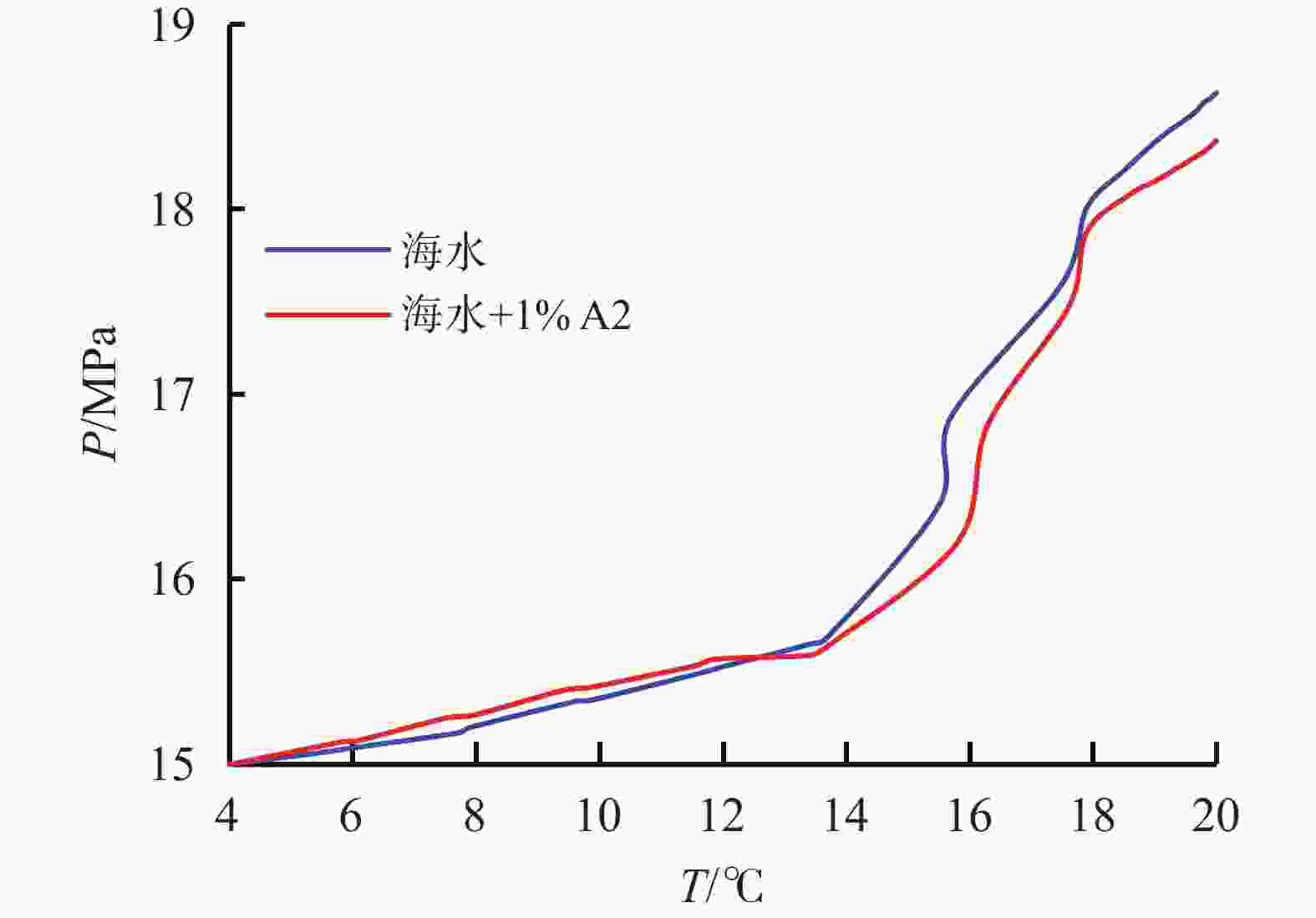

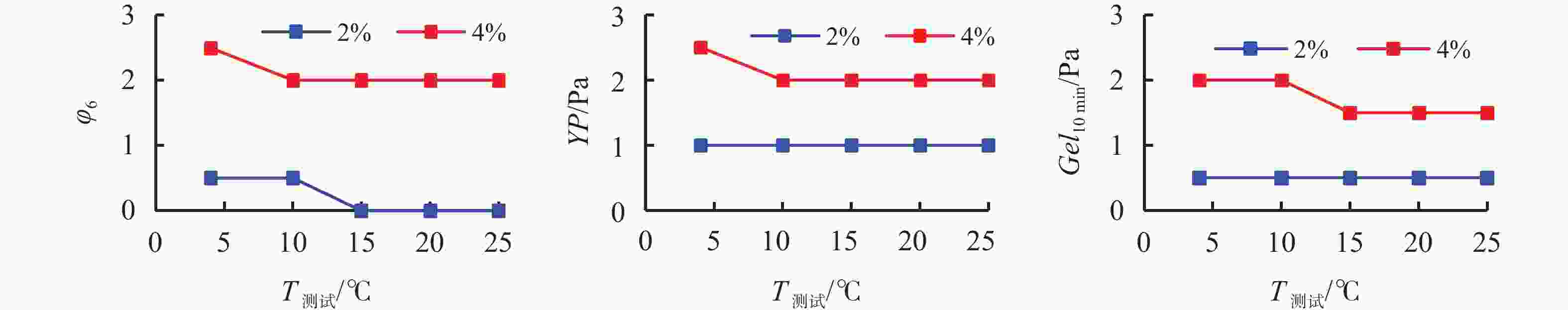

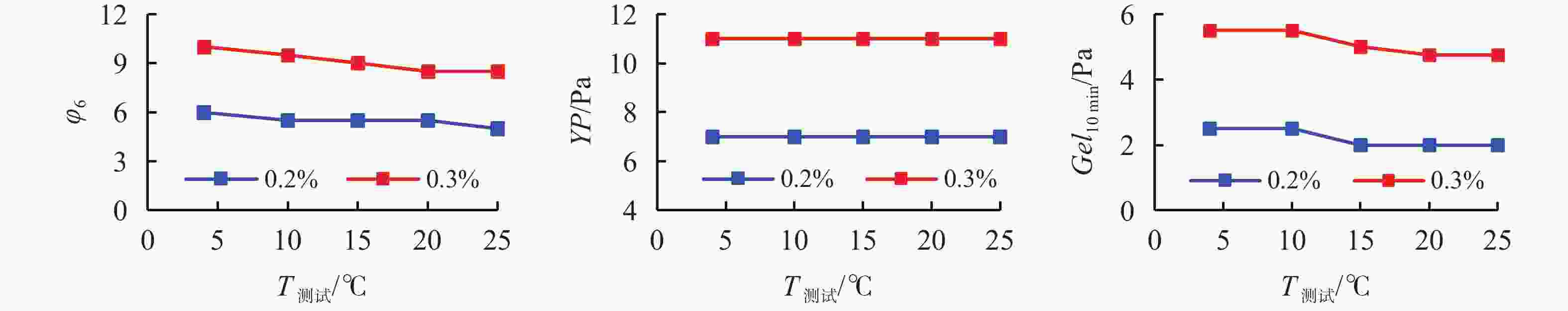

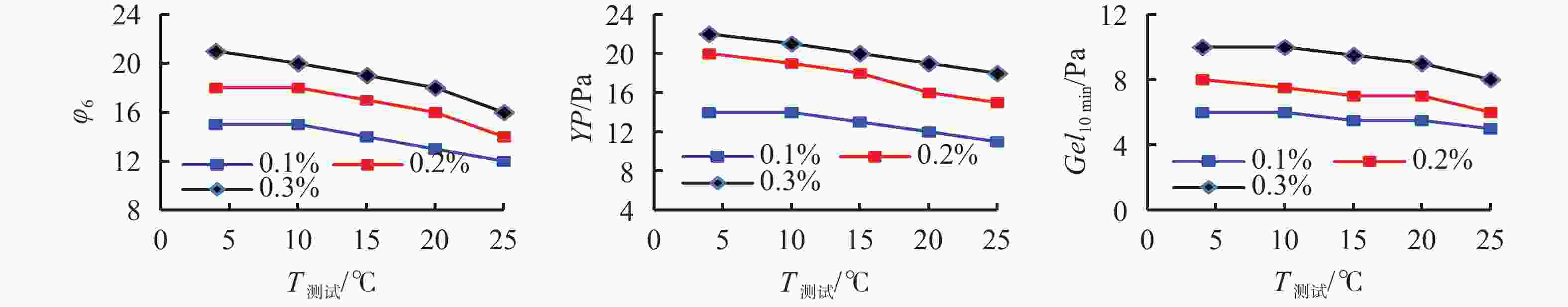

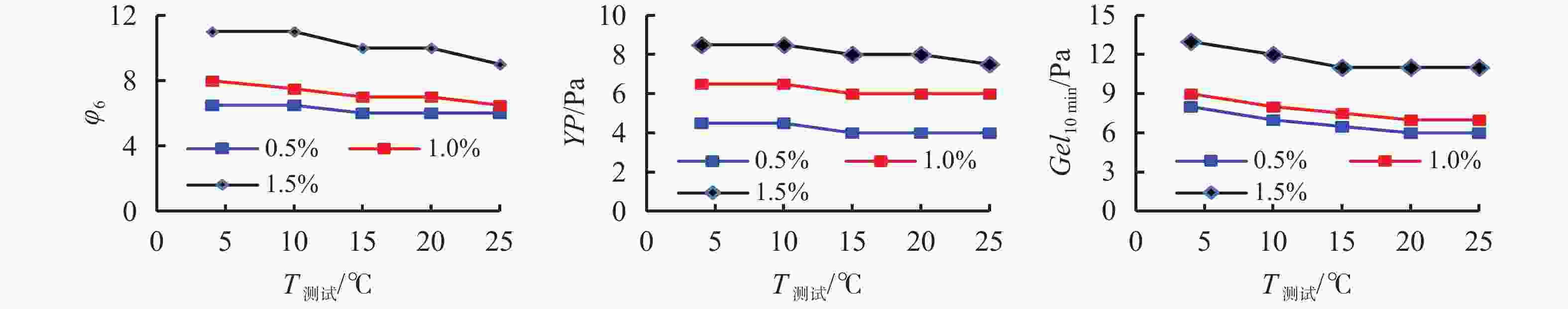

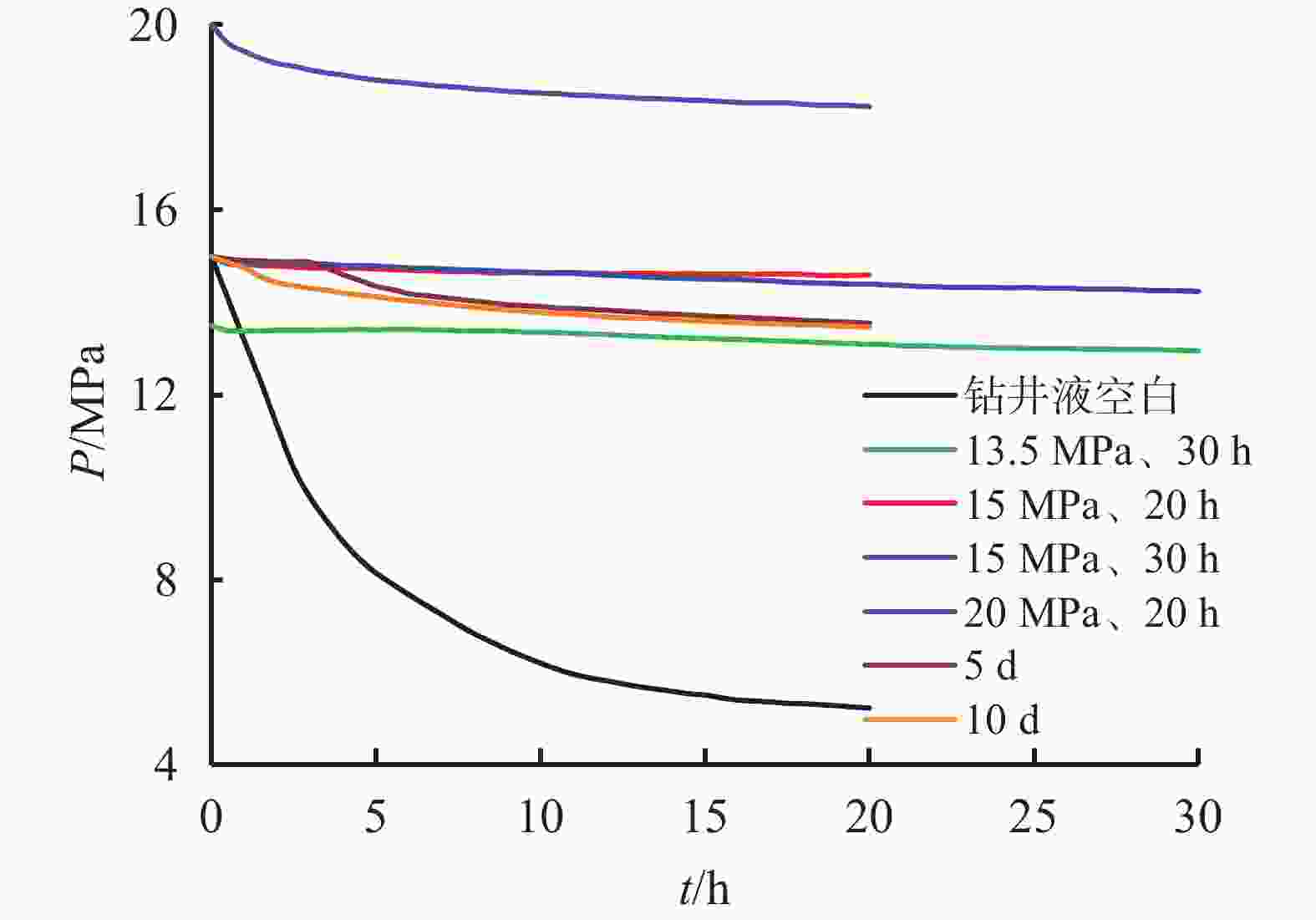

摘要: 针对海域天然气水合物钻探所面临的深水低温、浅层窄安全密度窗口、水合物生成与分解抑制、海洋作业环保要求等工程和技术难题,开发了低温抑制性钻井液体系。研发了热力学抑制剂KCl复配动力学抑制剂A2的水合物抑制技术,优选了低温流变稳定性能良好的高分子处理剂,开发的钻井液体系流变性能良好,膨润土含量为2 %,API滤失量为4 mL,密度为1.07 g/cm3;低温流变稳定性优良,4 ℃较25 ℃时钻井液当量循环密度最大增量为0.004 g/cm3,优良的流变学性能有利于深水浅部地层窄安全密度窗口井段的井壁稳定和井眼清洁。该体系还具有优异的水合物生成抑制性能,4 ℃、20 MPa、20 h内完全抑制水合物生成,陈化10 d及被钻屑污染后抑制性能保持良好,同时具备明显的水合物分解抑制性能。各处理剂重金属含量达标,钻井液体系生物毒性半有效浓度EC50值及半致死浓度LC50值均大于30 000 mg/L,满足我国一级海区环保要求。该钻井液的综合技术性能满足海域天然气水合物钻探技术要求。Abstract: A low temperature inhibitive drilling fluid was developed for use in offshore natural gas hydrate drilling to deal with several technical challenges such as low temperature in deep waters, narrow safe drilling window in shallow formations, inhibition of the formation and decomposition of gas hydrate and requirements on environment protection etc. The low temperature inhibitive drilling fluid was formulated with a gas hydrate inhibitor, which was developed by compounding the thermodynamic inhibitor KCl and a kinetic inhibitor A2, and high molecular weight additives with superior low temperature rheology stability. This drilling fluid has good rheology. The bentonite content, API filter loss and density of this drilling fluid are 2%, 4 mL and 1.07 g/cm3, respectively. It has a stable low temperature rheology: the ECD at 4 ℃ is only 0.004 g/cm3 (max.) higher than that of the drilling fluid at 25 ℃. This excellent rheological property is beneficial to the borehole wall stability and borehole cleaning in drilling the shallow formations in deep waters with narrow safe drilling windows. This drilling fluid also shows excellent performance in inhibiting the formation of gas hydrate. At 4 ℃ and 20 MPa, gas hydrate is completely inhibited in 20 h. After aging for 10 d and being contaminated with drilled cuttings, the drilling fluid still retains good inhibitive capacity, and is able to decompose the gas hydrate formed. The contents of heavy metals in the additives used to formulate the drilling fluid meet the requirements of relevant standards, the EC50 and LC50 of the drilling fluid are all greater than 30 000 mg/L, satisfying the needs of first-level environment protection in the sea area in China. The overall technical performance of this drilling fluid satisfies the technical requirements of drilling natural gas hydrate in offshore area.

-

表 1 不同配方钻井液的流变性能

配方 T/

℃AV/

mPa·s△AV/

%PV/

mPa·s△PV/

%YP/

Pa△YP/

%φ6/φ3 Gel/

Pa/PaFLAPI/

mLρ/

g·cm−31# 25 45.0 77.8 30 73.3 15.0 86.7 7.0/6.0 3/3.5 3.5 1.09

1.094 80.0 52 28.0 8.0/7.0 4.0/4.0 3.5 2# 25 43.0 60.5 28 60.7 15.0 60.0 7.0/6.0 3.5/4.0 3.5 1.09

1.094 69.0 45 24.0 8.0/7.0 3.5/4.0 3.5 3# 25 34.0 54.4 24 54.2 10.0 55.0 4.5/4.0 2.0/3.0 4.0 1.09

1.094 52.5 37 15.5 6.0/5.0 2.5/3.0 4.0 4# 25 22.5 40.0 17 41.2 5.5 36.4 2.0/2.0 1.0/1.5 6.0 1.07

1.074 31.5 24 7.5 2.0/2.0 1.5/1.5 6.0 5# 25 25.0 42.0 19 42.1 6.0 41.7 2.0/2.0 1.0/1.5 5.0 1.07

1.074 35.5 27 8.5 2.5/2.5 1.5/2.0 5.0 6# 25 43.5 40.2 31 35.5 12.5 52.0 6.0/4.0 2.0/3.0 4.0 1.07 4 61.0 42 19.0 7.0/5.0 3.0/3.5 4.0 1.07 表 2 重金属含量限值及不同处理剂检测结果

限制/样品 测试结果/(mg·kg−1) 汞 镉 砷 铅 铬 限值 1 3 75 1000 1000 低温流型调节剂

BDV-110S0.08 0.92 <0.1 2.48 22.3 低温降滤失剂BDF-600S 0.05 0.32 4.22 13.30 187 低温包被抑制剂

BDFL-120S0.11 1.06 <0.1 0.267 24.8 水合物动力抑制剂A2 0.04 0.25 <0.1 未检出 5.38 表 3 不同处理剂及体系的生物毒性EC50

处理剂 EC50/(mg·L−1) 低温流型调节剂BDV-110S 75 120 低温降滤失剂BDF-600S 72 500 低温包被抑制剂BDFL-120S 40 740 水合物动力抑制剂A2 115 490 水合物钻井液体系 39 240 -

[1] 朱秋格. 天然气水合物——21世纪的潜在能源[J]. 特种油气藏,2004,11(1):5-8. doi: 10.3969/j.issn.1006-6535.2004.01.002ZHU Qiuge. Natural gas hydrate——alternative energy in the 21st century[J]. Special Oil and Gas Reservoirs, 2004, 11(1):5-8. doi: 10.3969/j.issn.1006-6535.2004.01.002 [2] 李丽松,苗琦. 天然气水合物勘探开发技术发展综述[J]. 天然气与石油,2017,32(1):67-71.LI Lisong, MIAO Qi. Overview of development of gas hydrate exploration and development technology[J]. Natural Gas and Oil, 2017, 32(1):67-71. [3] 涂运中. 海洋天然气水合物地层钻井的钻井液研究[D]. 武汉: 中国地质大学, 2010.TU Yunzhong. The study on drilling fluid for drilling in marine natural gas hydrate bearing formations[D]. Wuhan: China University of Geosciences, 2010. [4] MATSUZAWA M, UMEZU S, YAMAMOTO K. Evaluation of experiment program 2004: Natural hydrate exploration campaign in the Nankai-Trough offshore Japan[C]. IADC/SPE, 98960, 2006. [5] 张凌,蒋国盛,蔡记华,等. 低温地层钻进特点及其钻井液技术现状综述[J]. 钻井液与完井液,2006,23(4):69-72,93. doi: 10.3969/j.issn.1001-5620.2006.04.021ZHANG Ling, JIANG Guosheng, CAI Jihua, et a1. Overview of low temperature formation characteristics while drilling and available drilling fluid technology[J]. Drilling Fluid & Completion Fluid, 2006, 23(4):69-72,93. doi: 10.3969/j.issn.1001-5620.2006.04.021 [6] 张寒松. 清洁能源可燃冰研究现状与前景[J]. 应用能源技术,2014(8):54-58. doi: 10.3969/j.issn.1009-3230.2014.08.014ZHANG Hansong. Research situation and prospects of flammable ice as a clean energy[J]. Applied Energy Technology, 2014(8):54-58. doi: 10.3969/j.issn.1009-3230.2014.08.014 [7] 刘华,李相方,夏建蓉,等. 关于天然气水合物钻采工艺技术进展的研究[J]. 钻采工艺,2006,29(5):54-57. doi: 10.3969/j.issn.1006-768X.2006.05.019LIU Hua, LI Xiangfang, XIA Jianrong, et al. Research on the progress of drilling and production technology of natural gas hydrate[J]. Drilling & Production Technology, 2006, 29(5):54-57. doi: 10.3969/j.issn.1006-768X.2006.05.019 [8] 宫智武,张亮,程海清,等. 海底天然气水合物分解对海洋钻井安全的影响[J]. 石油钻探技术,2015,43(4):19-24.GONG Zhiwu, ZHANG Liang, CHENG Haiqing, et al. The influence of subsea natural gas hydrate dissociation on the safety of offshore drilling[J]. Petroleum Drilling Techniques, 2015, 43(4):19-24. [9] 邱存家,陈礼仪,朱宗培,等. 天然气水合物钻探中钻井液的使用[J]. 探矿工程,2002,36(4):36-37.QIU Cunjia, CHEN Liyi, ZHU Zongpei, et al. The use of drilling fluid in gas hydrate drilling[J]. Exploration Engineering, 2002, 36(4):36-37. [10] 徐家放,邱正松,毕波,等. 深水水基钻井液的配方优选与性能评价[J]. 钻井液与完井液,2011,28(4):4-7. doi: 10.3969/j.issn.1001-5620.2011.04.002XU Jiafang, QIU Zhengsong, BI Bo, et al. Formulation optimization and performance evaluation of deepwater water-based drilling fluid[J]. Drilling Fluid & Completion Fluid, 2011, 28(4):4-7. doi: 10.3969/j.issn.1001-5620.2011.04.002 [11] 涂运中,蒋国盛,张昊,等. 海洋天然气水合物钻井的硅酸盐钻井液研究[J]. 现代地质,2009,23(2):224-228. doi: 10.3969/j.issn.1000-8527.2009.02.005TU Yunzhong, JIANG Guosheng, ZHANG Hao, et al. Study on silicate drilling fluid for drilling in marine gas hydrate bearing sediments[J]. Geoscience, 2009, 23(2):224-228. doi: 10.3969/j.issn.1000-8527.2009.02.005 [12] TAN C P. FREIJ-AYOUB R, CLENNELL M B, et a1. Managing wellbore instability risk in gas-hydrate beating sediments[J]. SPE, 9296, 0:2005. [13] RODGER P M. Simulation of surface melting and inhibition in clathrate hydrates[M]. 8th International Symposium on Molecular Recognition and Inclusion. Ottawa: Carleton University, 1994. [14] GEORGE D S, HYNDMAN R D. The challenge of deep ocean drilling for natural gas hydrate[J]. Geoscience Canada, 2001, 28(4):179-186. [15] KELLAND M A, IVERSEN J E, LEKVAMK. Feasibility study for the use of kinetic hydrate inhibitors in deep-water drilling fluids[J]. Energy Fuels, 2008, 22(4):2405-2410. doi: 10.1021/ef800109e [16] 赵欣,邱正松,黄维安,等. 天然气水合物热力学抑制剂作用机制及优化设计[J]. 石油学报,2015,36(6):760-766. doi: 10.7623/syxb201506014ZHAO Xin, QIU Zhengsong, HUANG Weian, et al. Inhibition mechanism and optimized design of thermodynamic gas hydrate inhibitors[J]. Acta Petrolei Sinica, 2015, 36(6):760-766. doi: 10.7623/syxb201506014 [17] JOHN LEE, DARYL CULLUM, JIM FRIEDHEIM, et a1. A new sbm for narrow margin extended reach drilling[J]. IADC/SPE, 1514, 69:2012. -

下载:

下载: