Preparation of Salt Tolerant Suspension Dispersion Polymer System and its Application in Brine-based Variable Viscosity Slippery Water System

-

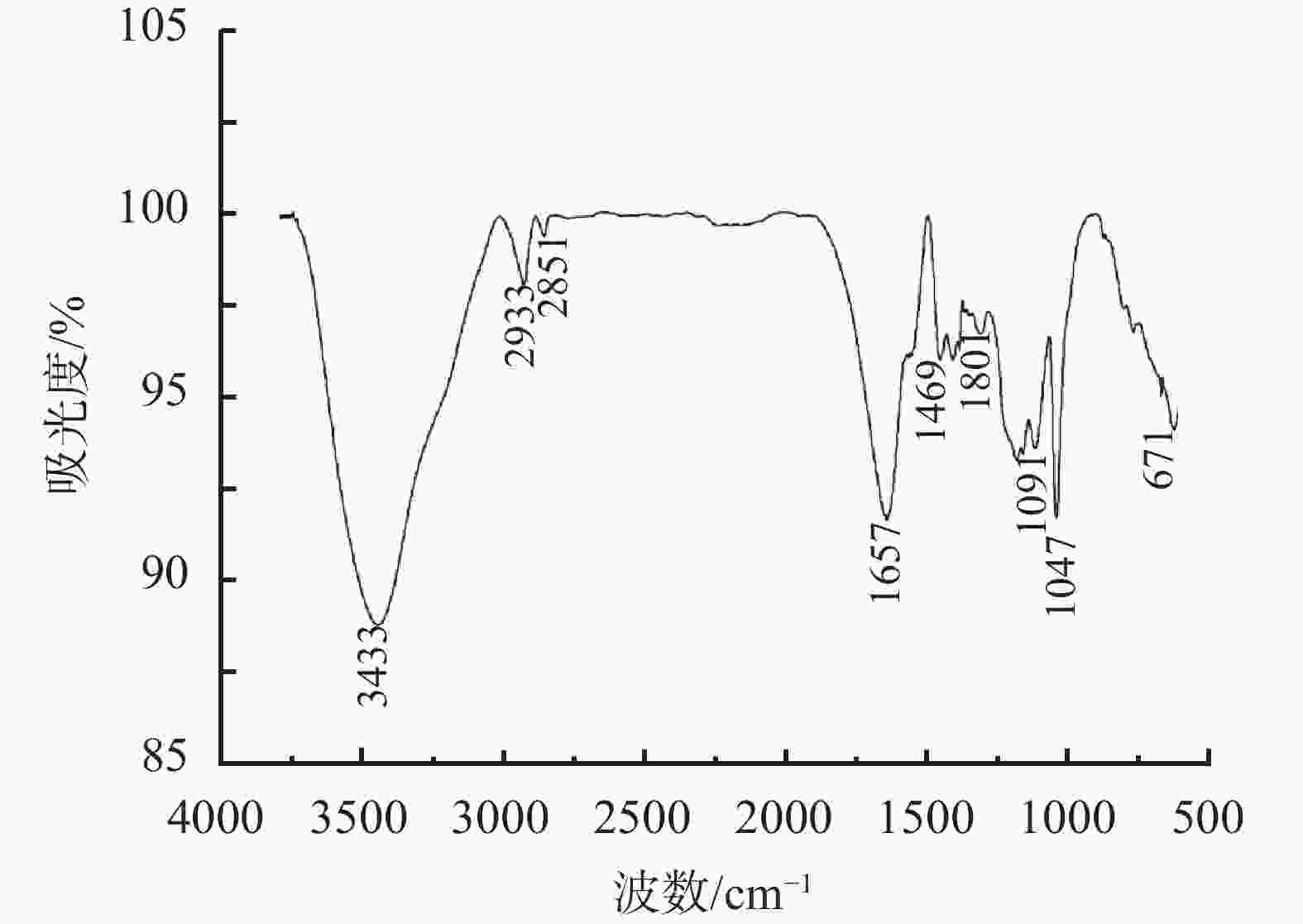

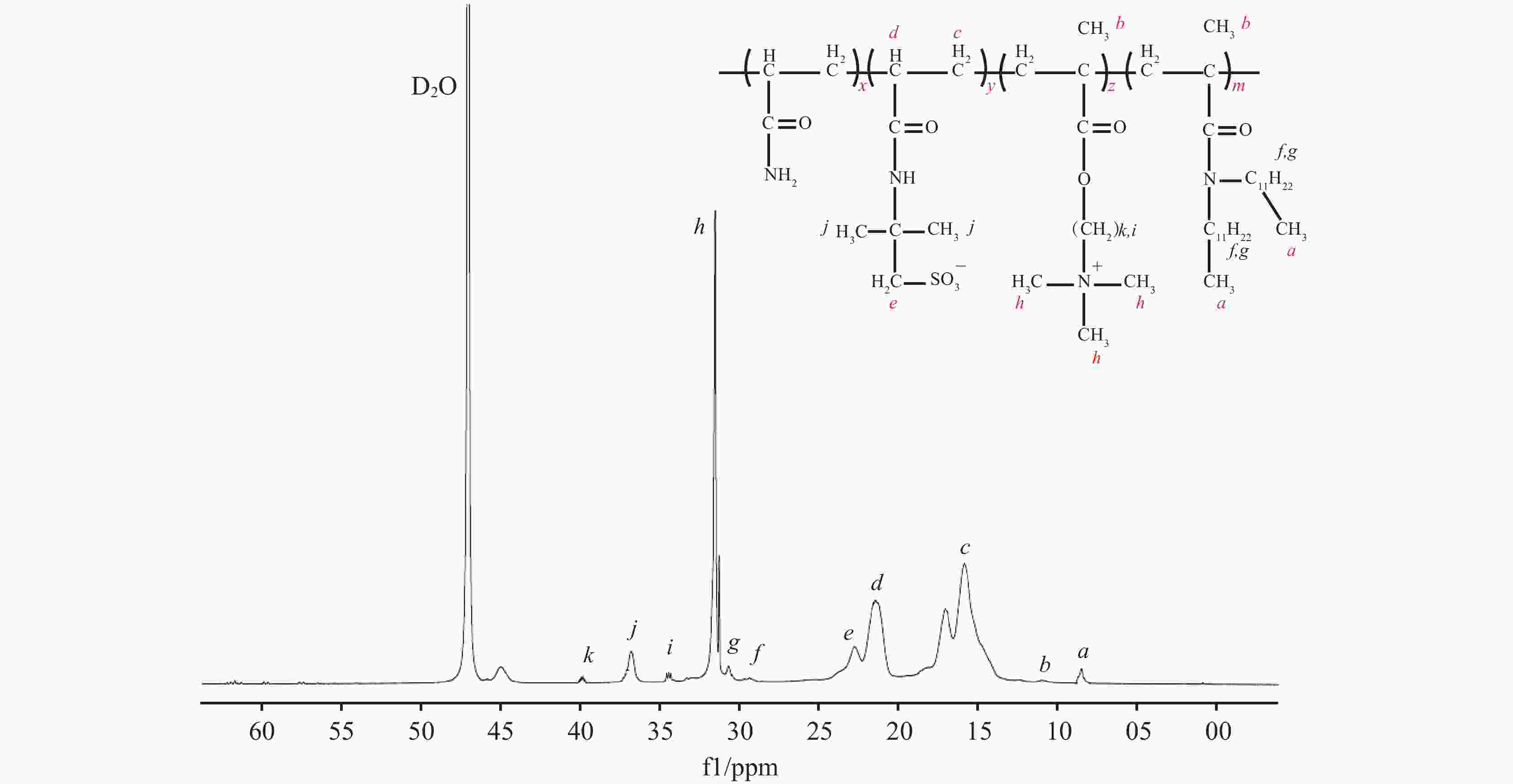

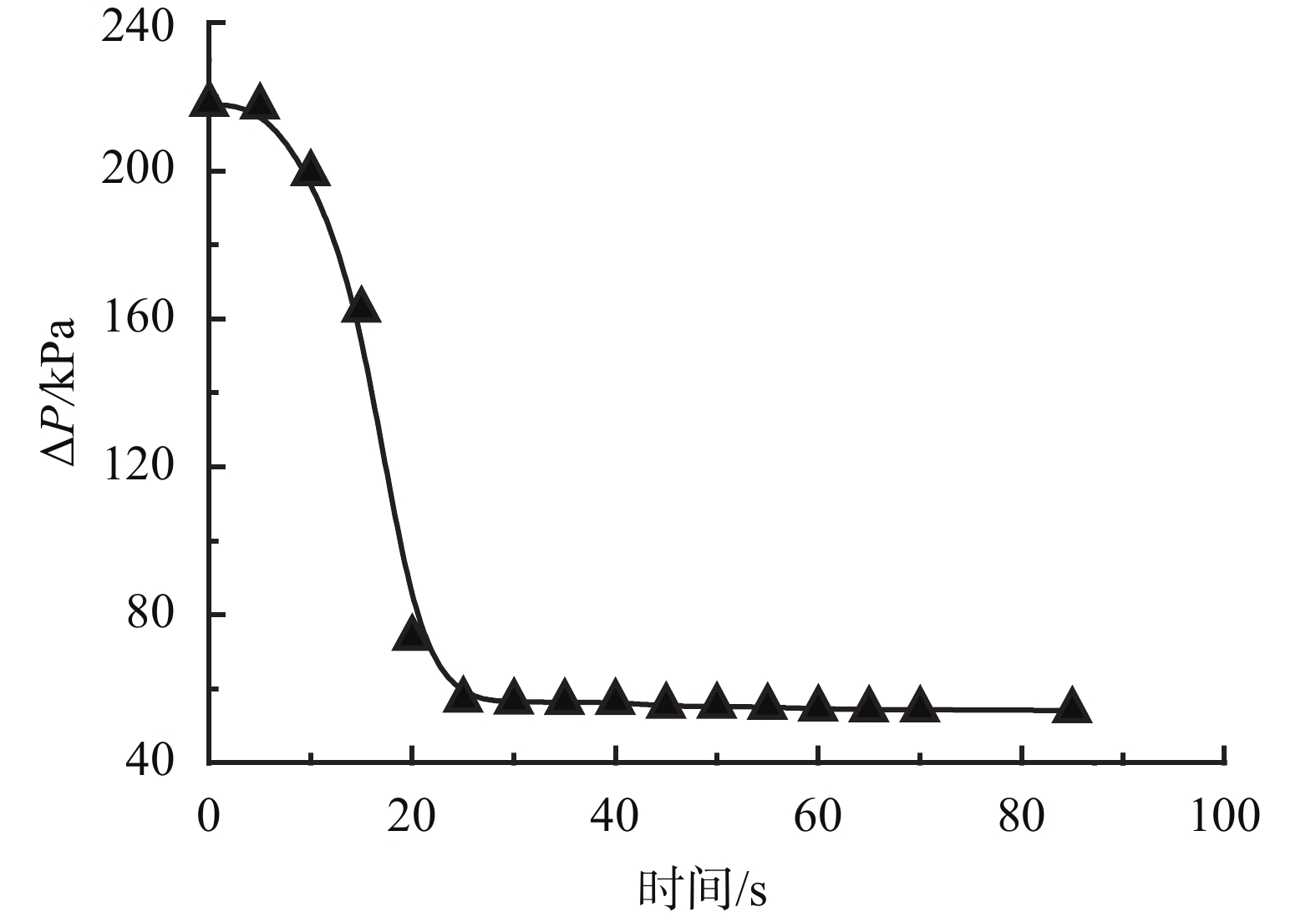

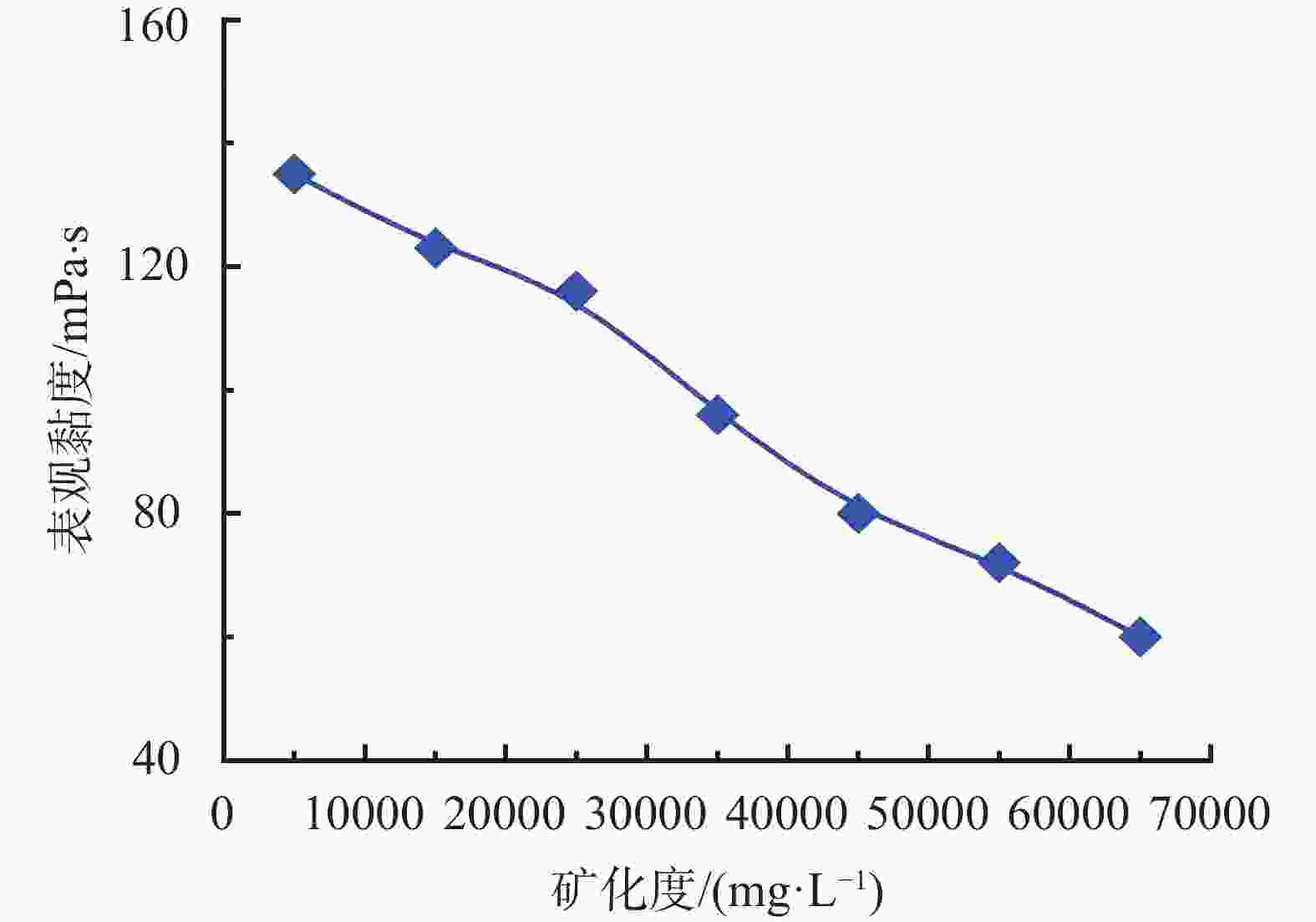

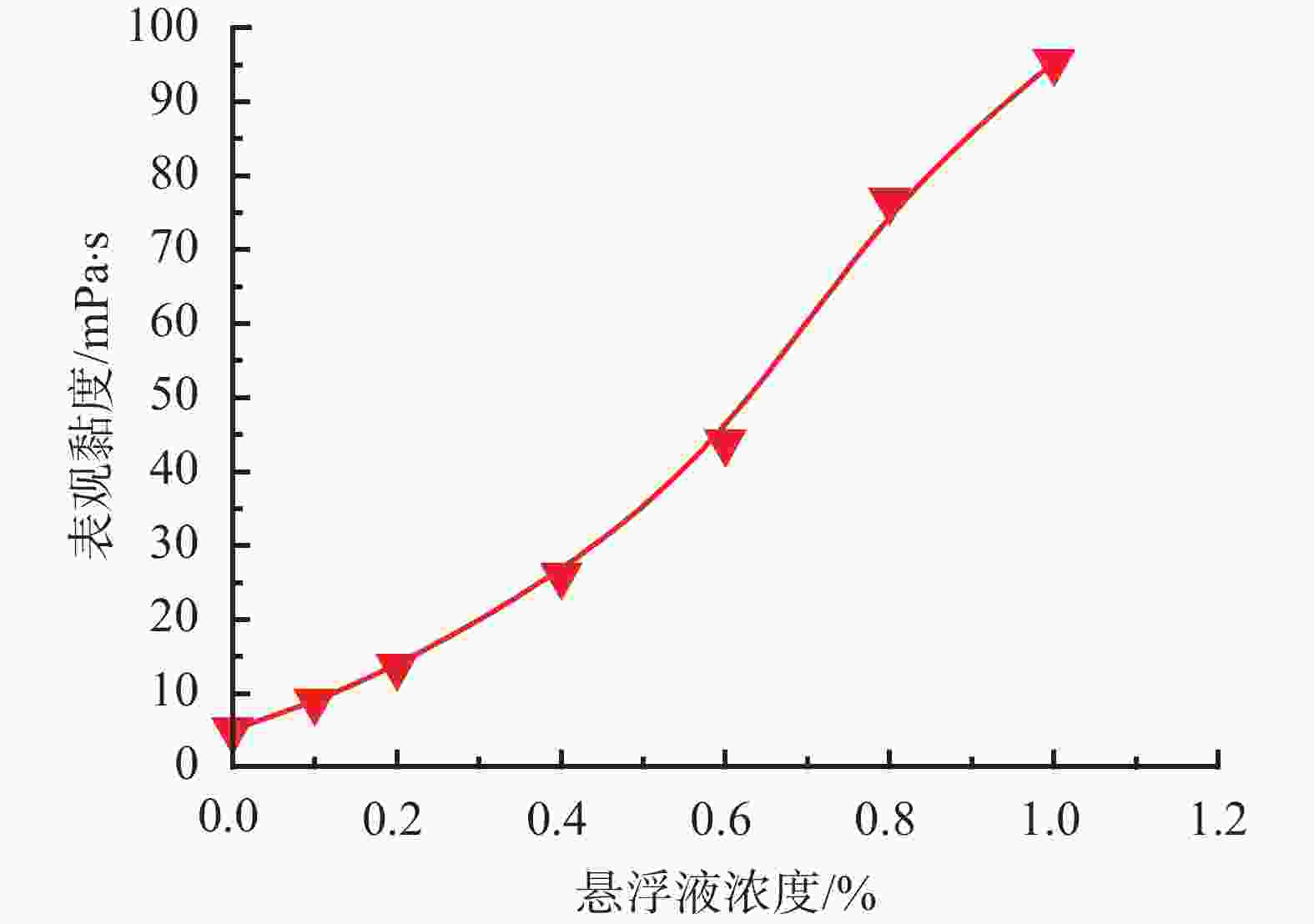

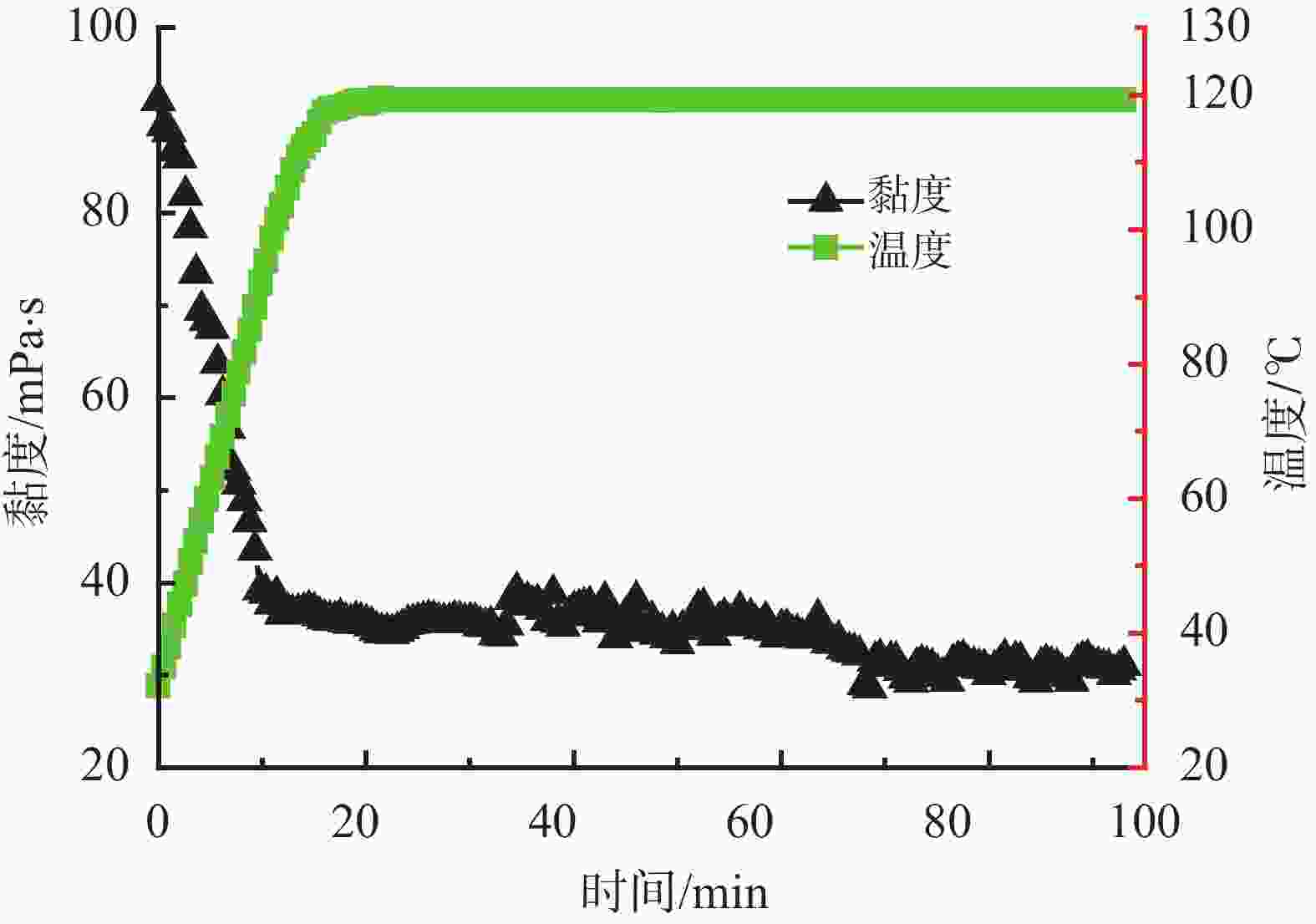

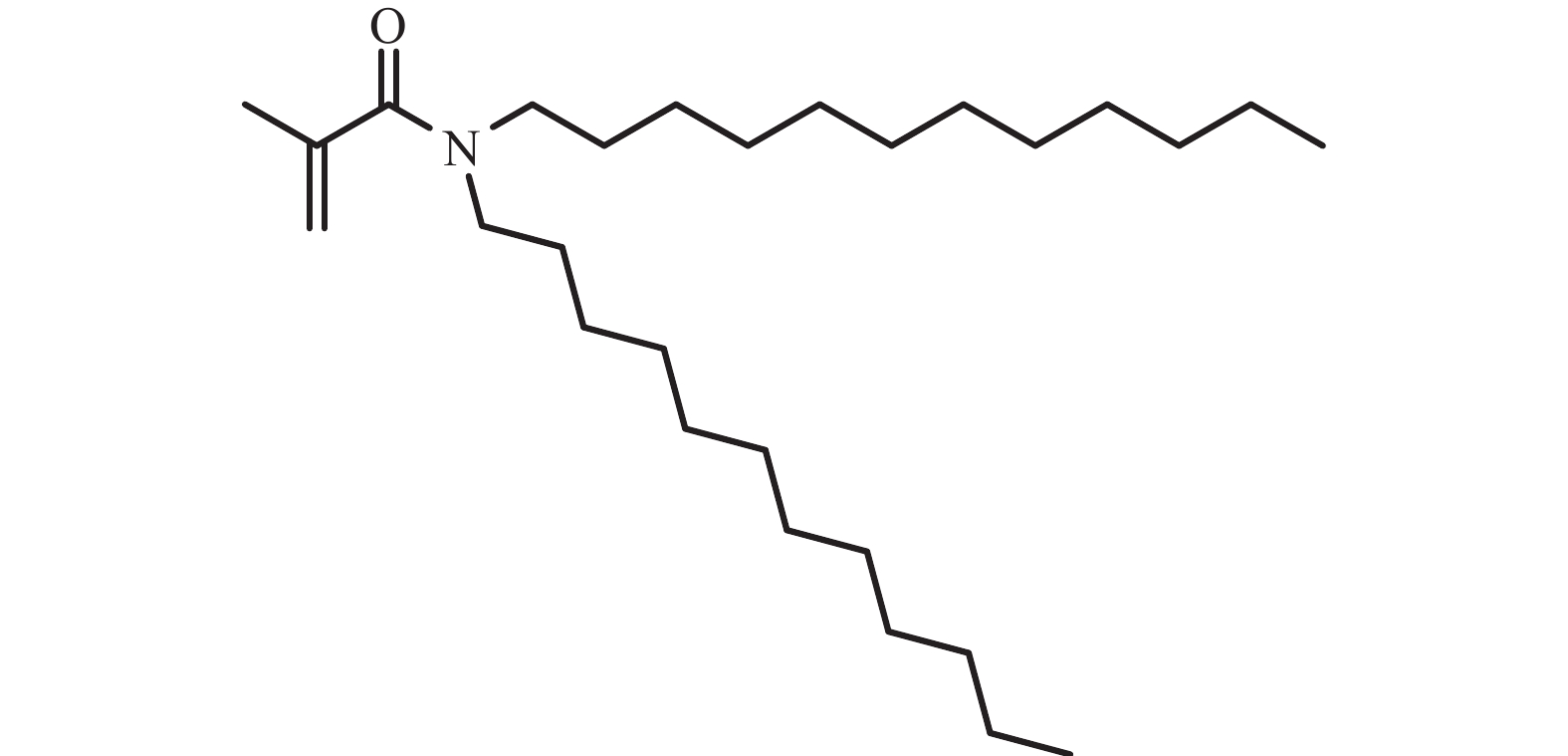

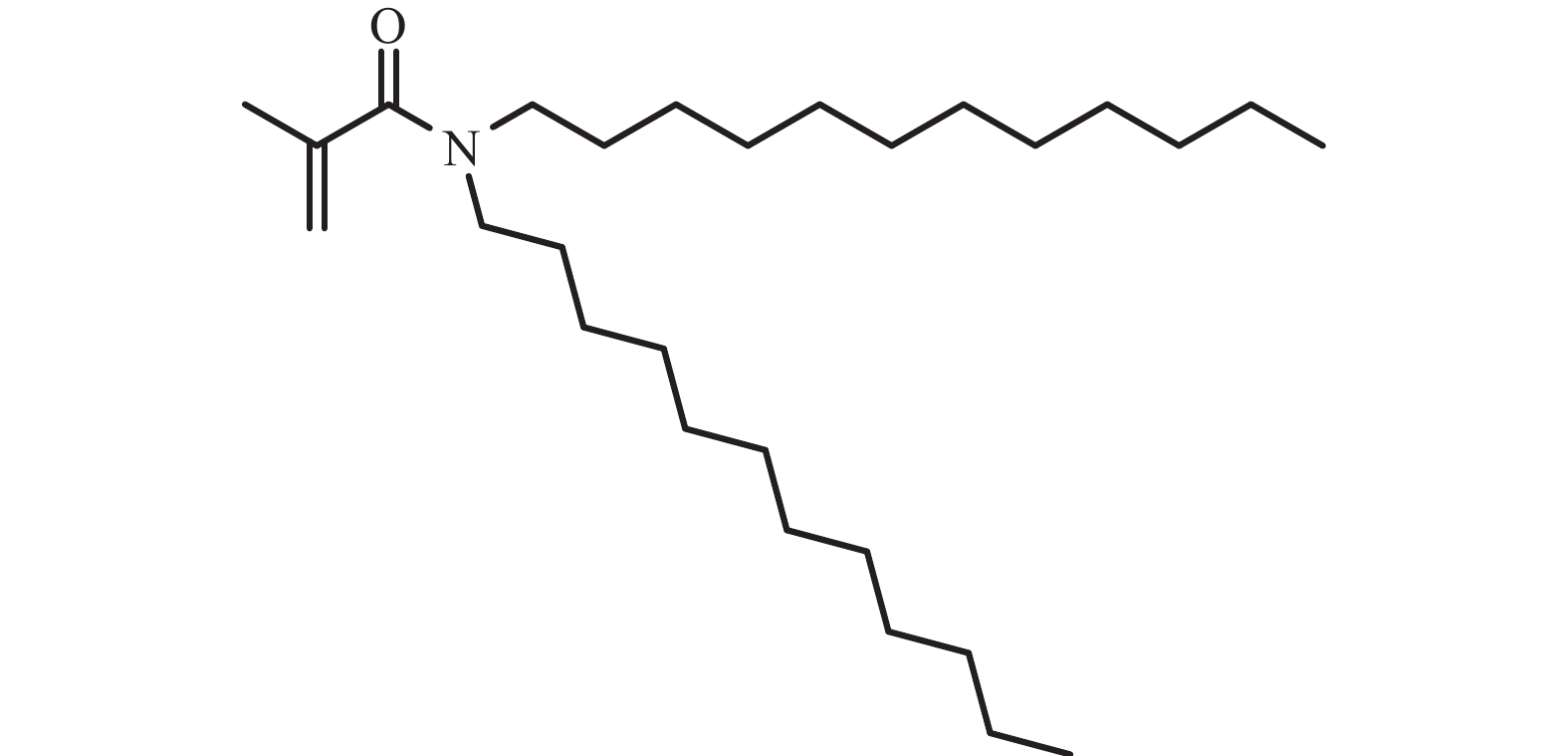

摘要: 通过水溶液聚合体系研制出含双尾疏水单体的两性离子型聚合物分子P-DHZ,黏均分子量达到1000万以上,其具有极佳的耐盐型、减阻性与成胶性,可作为页岩气水力压裂液减阻剂或稠化剂利用高矿化返排液直接配液,耐盐能力可达6×104 mg/L。为满足页岩气压裂现场连续混配的工艺需求,将研制出的P-DHZ制成粉剂,分散于烃类连续相中形成稳定的悬浮体系,并优选出最佳的粉剂粒径、分散剂、转向剂及烃类连续相,制备出可用于现场连续混配的悬浮体系,粉剂比例占体系的45%,在高矿化度返排液中的溶解时间低于30 s,其最高减阻率达到75%以上,并可通过调整浓度实现实时变黏,迅速由滑溜水体系转变为胶液体系。Abstract: In this paper, the zwitterionic polymer molecule P-DHZ containing double tailed hydrophobic monomer was developed by aqueous solution polymerization system. Its viscosity average molecular weight is more than 10 million. It owns excellent salt resistance, drag reduction and gelling properties. It can be used as a drag reducer or thickener for shale gas hydraulic fracturing fluid, and can be directly prepared with highly mineralized backflow fluid. Its salt resistance can reach 60 000 mg/L. In order to meet the process requirements of continuous mixing in shale gas fracturing field, P-DHZ powder was prepared and dispersed in hydrocarbon continuous phase to form a stable suspension system. The best powder size, dispersant, diverting agent and hydrocarbon continuous phase were selected to prepare a suspension system for continuous mixing in field. The proportion of powder accounted for 45% of the suspension system, and it can be solved in high salinity back-flow fluid to prepare fracturing fluid without fresh water resource. The maximum drag reduction rate is more than 75%, and the dissolution time is less than 30 seconds. The viscosity can be changed in real time by adjusting the concentration, and the slick-water system can be quickly transformed into the glue system.

-

Key words:

- salt tolerance /

- suspension system /

- rapid solution preparation /

- real time viscosity /

- shale gas

-

表 1 采用不同矿化度配制的0.1%悬浮液溶液的减阻效果测试结果

矿化度/

mg·L−1悬浮液/

%t溶解/

s减阻效果 最高减

阻率/%最低减

阻率/%平均减

阻率/%10 000 0.1 23 78.3 77.9 78.10 20 000 0.1 23 78.1 78.0 78.05 30 000 0.1 26 78.1 77.5 77.80 50 000 0.1 28 77.9 77.6 77.75 60 000 0.1 30 77.5 77.3 77.40 表 2 不同加量的聚合物悬浮液在返排液中溶解时间及减阻效果

悬浮液/

%溶解时间/

s减阻效果 最高减

阻率/%最低减

阻率/%平均减

阻率/%0.1 25 78.1 77.6 77.85 0.2 28 79.2 78.3 78.75 0.3 36 72.6 71.9 72.25 0.4 43 65.9 63.6 64.75 表 3 各压裂液体系静态悬砂实验测试结果

T/℃ 60 80 90 沉降速度/(mm·s−1) 7.71×10−3 1.21×10−2 2.38×10−2 表 4 聚合物悬浮体系配制的滑溜水体系与胶液体系在90 ℃下的破胶性能

压裂液

体系APS/

mg/Lt破胶/

min表面张力/

mN/m界面张力/

mN/m残渣含量/

mg/L滑溜水

体系100 50 25.3 0.186 0 胶液

体系400 100 26.6 0.399 56 -

[1] 李武广,杨胜来,殷丹丹,等. 页岩气开发技术与策略综述[J]. 天然气与石油,2011(1):34-37. doi: 10.3969/j.issn.1006-5539.2011.01.009LI Guangwu, YANG Shenglai,YIN Dandan, et al. Development technology and strategy of shale gas[J]. Nature Gas and Oil, 2011(1):34-37. doi: 10.3969/j.issn.1006-5539.2011.01.009 [2] 唐颖,唐玄,王广源,等. 页岩气开发水力压裂技术综述[J]. 地质通报,2011,30(2):393-399.TANG Ying, TANG Xuan,WANG Guangyuan et al. Summary of hydraulic fracturing technology in shale gas development[J]. Geological Bulletin of China, 2011, 30(2):393-399. [3] 黄凯,靳纪军,张洪坤. 非常规能源页岩气开采技术研究[J]. 内蒙古石油化工,2012(18):89-92. doi: 10.3969/j.issn.1006-7981.2012.18.037HUANG Kai, JIN Jijun, ZHANG Hongshen, et al. Research on unconventional energy shale gas production technology[J]. Inner Mongolia Petrochemical Industry, 2012(18):89-92. doi: 10.3969/j.issn.1006-7981.2012.18.037 [4] 李雪凝, 宋磊, 王毅霖. 浅析页岩气开发的环境影响[C]. 中国环境科学学会学术年会. 2014.LI Xuening, SONG Lei, WANG Yilin. Analysis on the environmental impact of shale gas development [C]. Annual meeting of Chinese society of Environmental Sciences. 2014 [5] 魏娟明,刘建坤,杜凯,等. 反相乳液型减阻剂及滑溜水体系的研发与应用[J]. 石油钻探技术,2015,43(1):27-32.WEI Juanming, LIU Jiankun, DU Kai, et al. The development and application of inverse emulsified friction reducer and slickwater system[J]. Petroleum Drilling Techniques, 2015, 43(1):27-32. [6] 杜凯,林蔚然,祝纶宇,等. 生物基反相乳液型降阻剂与滑溜水体系的研发与评价[J]. 化工新型材料,2015(5):221-223.DU Kai, LIN Weiran, ZHU Lunyu,et al. Development and evaluation of bio-inverse emulsified friction reducer and slickwater system[J]. New Chemical Materials, 2015(5):221-223. [7] 李嘉,何启平,蔡远红,等. 反相乳液降阻剂合成及其应用[J]. 天然气工业,2014,34(S1):27-30. doi: 10.3787/j.issn.1000-0976.2014.s1.007LI Jia, HE Qiping, CAI Yuanhong, et al. Synthesis and application of inverse emulsified friction reducer[J]. natural gas industry, 2014, 34(S1):27-30. doi: 10.3787/j.issn.1000-0976.2014.s1.007 [8] 何静,王满学,吴金桥,等. 多功能滑溜水减阻剂的制备及性能评价[J]. 油田化学,2019,139(1):52-56.HE Jing, WANG Manxue, WU Jinqiao,et al. Preparation and performance evaluation of a multi-functional drag reducing agent used in slick water fracturing fluid[J]. Oilfield Chemistry, 2019, 139(1):52-56. [9] 曹正权,姜娜,陈辉,等. 聚丙烯酰胺/溶性酚醛树脂反相乳液水分散液的成胶性能[J]. 油田化学,2008(1):63-63. doi: 10.3969/j.issn.1000-4092.2008.01.016CAO Zhengquan, JIANG Na, CHEN Hui,et al. Gelation behavior of polyacrylamide/phenolic resin inverse emulsion dispersed in water[J]. Oilfield Chemistry, 2008(1):63-63. doi: 10.3969/j.issn.1000-4092.2008.01.016 [10] MAO Jincheng , TAN Hongzhong , et al. Novel hydrophobic associating polymer with good salt tolerance[J]. Polymers, 2018, 10(8):849. doi: 10.3390/polym10080849 [11] 张锋三,沈一丁,任婷,等. 聚丙烯酰胺压裂液减阻剂的合成及性能[J]. 化工进展,2016,33(12):1422-1422.ZHANG Fengsan, SHEN Yiding, REN Ting,et al. Synthesis and properties of polyacrylamide drag reducer for fracturing fluid[J]. Chemical Industry and engineering progress, 2016, 33(12):1422-1422. [12] 刘彝,刘京,颜菲,等. 缔合非交联压裂液储层伤害特征[J]. 海洋石油,2018,38(04):61-65.LIU Yi, LIU Jing, YAN Fei,et al. The characteristics about the damage of associated non cross-linking fracturing fluid to reservoirs[J]. Offshore Oil, 2018, 38(04):61-65. -

下载:

下载: