Drilling Fluid Technology for the Third Interval of Well Changtan-1 in Jilin Oilfield

-

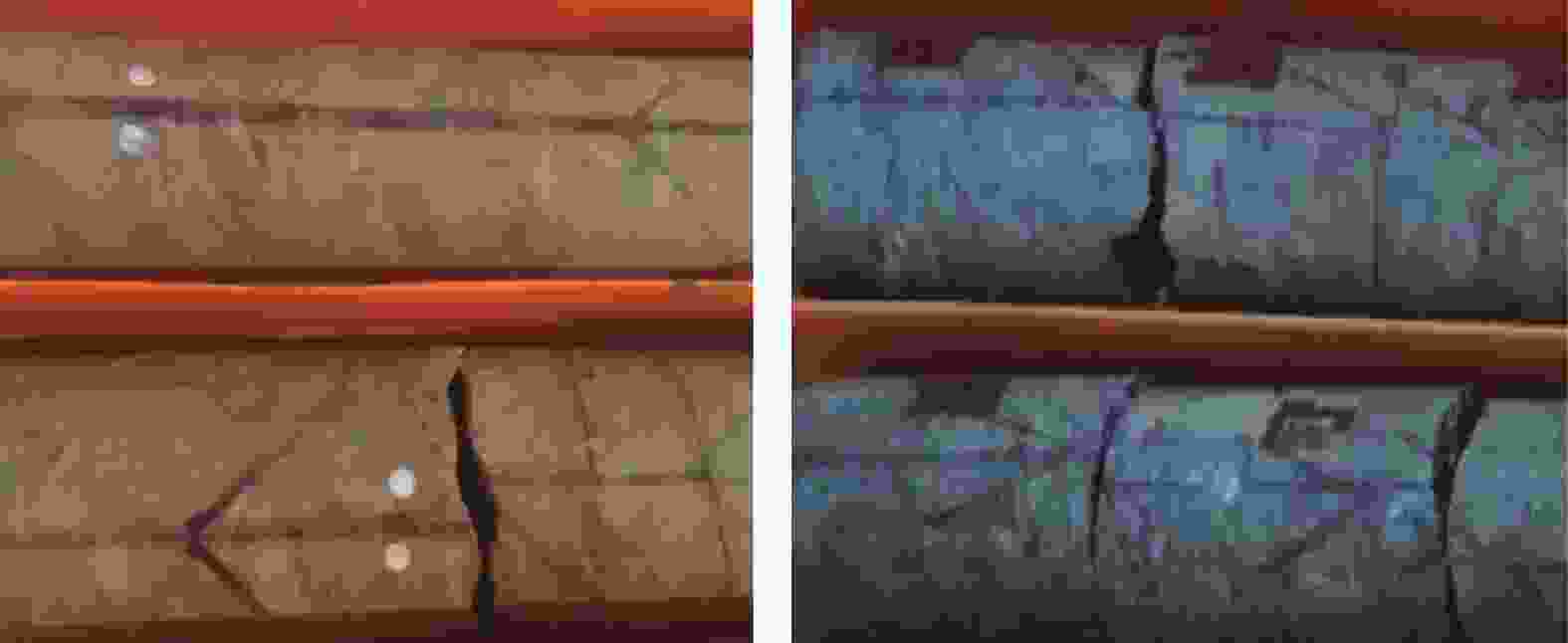

摘要: 长探1井是部署在松辽盆地南部长岭断陷神字井洼槽哈尔金构造上的一口风险探井,完井井深为5400 m。为解决该井三开井段中存在的井底温度高、设计密度低、火成岩地层坍塌掉块、二氧化碳侵等技术难点。经室内研究形成了一套抗温200 ℃、高温流变性好、封堵性强、有一定抗污染能力的抗温防塌水基钻井液体系,该钻井液利用磺酸盐共聚物降滤失剂的高温护胶作用提高了体系的抗温和抗污染能力,通过纳米二氧化硅提高了体系的流变调节和封堵能力。在现场应用中,该钻井液具有良好的高温稳定性,抑制了火成岩井段地层坍塌,高温流变性良好,解决了井底火成岩掉块携带问题;同时该体系具有较好的抗污染能力,在被二氧化碳污染后,仍具有较好的性能,且易于处理。该井顺利完井,期间无任何事故复杂发生,创松辽盆地南部长岭地区地层埋藏层位最深记录。Abstract: The well Changtan-1, 5400 m in total depth, is an exploratory well drilled in the Changling rift, south of the Songliao Basin. The third interval of this well penetrated formations with high temperatures and igneous formations which are sloughing in nature. The mud used to drill these formations had low densities based on the designed value, and CO2 contamination deteriorated the properties of the mud. To solve these problems, a drilling fluid having temperature resistance of 200 ℃, good high temperature rheology, high plugging capacity and a certain CO2 contamination resistance, was formulated through laboratory experiments. A sulfonate copolymer filtrate reducer in the drilling fluid rendered it good high temperature performance and contamination resistance through colloid protection at elevated temperatures by the copolymer. Treatment of the drilling fluid with a nanometer SiO2 improved the rheological property and plugging capacity. In field application, the drilling fluid showed good high temperature stability, and effectively inhibit the sloughing of the igneous rocks. After contaminated with CO2, the drilling fluid still retained satisfactory performance and the contamination was easy to treat out. The well Changtan-1 was successfully completed, no downhole troubles were encountered during drilling, and set the record of drilling the deepest well in the Changling area in the south of Songliao basin.

-

表 1 钻井液的抗温性能评价

老化条件 ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFL/

mLpH FLHTHP/

mL60 ℃ 1.20 45 16.5 3.0/7.0 9.5 180 ℃×16 h 1.20 38 16.0 4.0/10.5 3.0 9.5 12.4 190 ℃×16 h 1.20 41 19.0 4.5/13.0 3.2 9.5 13.8 200 ℃×16 h 1.20 41 21.5 5.5/15.5 3.2 9.5 15.6 60 ℃ 1.60 63 29.0 6.5/19.0 9.5 180 ℃×16 h 1.60 58 24.5 6.0/17.5 1.8 9.5 11.0 注:FLHTHP 在180 ℃测定 表 2 钻井液的热稳定性能评价

老化条件 ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFL/

mLpH FLHTHP/

mL180 ℃、24 h 1.20 38 16.5 4/10.5 3.0 9.5 12.4 180 ℃、48 h 1.20 42 18.0 4.5/12 3.2 9.5 12.8 180 ℃、72 h 1.20 43 20.5 6/15.5 3.2 9.5 13.6 注:FLHTHP 在180 ℃测定 表 3 钻井液的高温高压流变性能

T/

℃φ600 φ300 φ200 φ100 φ6 φ3 AV/

mPa·sPV/

mPa·sYP/

Pa60 141 85 67 50 12 10 70.5 56 14.5 90 116 70 53 33 9 7 58.0 46 12.0 120 78 46 33 23 8 6 39.0 33 6.5 150 59 36 28 20 6 5 28.5 23 6.5 180 44 28 22 16 5 5 22.0 16 6.0 表 4 高温高压渗透性封堵测试结果

砂岩

渗透率不同时间(min)的滤失量 /mL PPT/

mL恒定滤失

速率 /

mL·min −1/21 5 7.5 15 25 30 400 mD 0.6 1.8 2.8 3.6 4.0 4.6 9.2 1.31 10 D 1.5 2.7 3.5 4.4 5.4 6.2 12.4 1.97 100 D 2.4 3.6 4.4 5.7 6.9 7.8 15.6 2.48 表 5 180 ℃老化后黏土颗粒 Zeta 电位的变化

实验配方 Zeta电位/mV 4%膨润土 −22.54 4% 膨润土+2.0%BZ-JLS-Ⅰ+2.0%BZ-JLS-Ⅱ+2%SMP-1+2%SPNH −36.44 4% 膨润土+2.0%BZ-JLS-Ⅰ+2.0% BZ-JLS-Ⅱ+3%SMP-1+2%SPNH +1%NaCO3 −29.72 4% 膨润土+2.0% BZ-JLS-Ⅰ+2.0% BZ-JLS-Ⅱ+3%

SMP-1+2%SPNH +3%NaCO3−25.64 表 6 钻井液的抗污染能力评价

污染

条件老化

条件ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFL/

mLpH FLHTHP/

mL1%碳

酸钠60 ℃ 1.20 37 15.5 4.5/10.0 180 ℃、

16 h1.20 41 28.0 12/22.5 3.4 10.0 14 3%碳

酸钠60 ℃ 1.20 51 15.0 5.5/15.0 3.4 180 ℃、

16 h1.20 37.0/45.0 3.8 10.0 3%碳酸

钠+氧化

钙+水180 ℃、

16 h1.18 38 16.5 5.0/7.5 3.2 10.5 13.8 表 7 钻井液碳酸根污染处理前后性能

井

段/

mρ/

g·cm−3FV/

sPV/

mPa·sYP/

PaGel/

Pa/paFL/

mLFLHTHP/

mLCO32−+HCO3−/

mg·L−14510 1.20 79 26 21 12/21 3.2 14.0 5785.21 4619 1.20 130 25 37 22/38 3.4 15.0 10085.25 4646 1.19 80 24 21 13.5/24 3.3 13.6 6351.30 注:FLHTHP 在180 ℃测定 表 8 长探1井三开钻井液性能

井段/

mρ/

g·cm−3FV/

sPV/

mPa·sYP/

PaGel/

Pa/PaFL/

mLMBT/

g·L−1Vs/

%FLHTHP/

mL3486 1.17 53 23 9 3/9 3.2 43.75 13 14.0 3757 1.16 62 27 12 3.5/9 3.2 53.44 12 14.0 3892 1.18 70 33 17.5 7/17 3.2 57.00 14 13.0 4123 1.20 85 32 24 12.5/23 3.4 53.44 15 12.0 4310 1.19 79 26 20 11/19 3.4 57.00 15 14.8 4412 1.20 83 28 25 16/26 3.2 57.00 16 14.2 4619 1.20 130 25 37 22/38 3.4 64.13 15 15.0 4785 1.15 79 28 24 15/25 3.4 57.00 12 14.2 4977 1.15 78 26 23 14/24 3.3 57.00 12 14.0 5110 1.20 82 29 25 14/26 3.2 59.85 15 14.0 5200 1.20 84 31 26.5 16/26 3.2 64.13 15 14.4 注:表中3486~4123 m井段FLHTHP在150 ℃下测得,4310~5200 m井段FLHTHP在180 ℃下测得 -

[1] 王颖,邓守伟,范晶,等. 松辽盆地南部重点断陷天然气地质条件、资源潜力及勘探方向[J]. 天然气地球科学,2018,29(10):1455-1464.WANG Ying, DENG Shouwei, FAN Jing, et al. Natural gas geology, resource potential and favorable exploration direction in the south of Songliao basin[J]. Natural Gas Geoscience, 2018, 29(10):1455-1464. [2] 曹跃,高胜利,乔向阳,等. 松辽盆地南部长岭断陷营城组火山岩天然气成因与成藏[J]. 西安石油大学学报(自然科学版),2018,33(4):27-35.CAO Yue, GAO Shengli, QIAO Xiangyang, et al. Origin and accumulation of natural gas in volcanics of Yingcheng formation of Changling fault depression, southern Songliao basin[J]. Journal of Xi'an Shiyou University (Natural Science Edition) , 2018, 33(4):27-35. [3] 迟唤昭,董福湘,薛晓刚,等. 松辽盆地南部地区营城组典型火山机构地质特征[J]. 吉林大学学报(地球科学版),2019,49(6):1649-1657.CHI Huanzhao, DONG Fuxiang, XUE Xiaogang, et al. Geological characteristics of typical volcanic edifices of Yingcheng formation in southern Songliao basin[J]. Journal of Jilin University(Earth Science Edition) , 2019, 49(6):1649-1657. [4] 石秉忠. 松南地区 YS-2 井火成岩地层欠平衡钻井液技术[J]. 钻井液与完井液,2014,31(6):82-8.SHI Bingzhong. Underbalanced drilling fluid technology for well SY-2 in drilling igneous rocks[J]. Drilling Fluid & Completion Fluid, 2014, 31(6):82-8. [5] 王璞珺,陈崇阳,张英,等. 松辽盆地长岭断陷火山岩储层特征及有效储层分布规律[J]. 天然气工业,2015,35(08):10-18.WANG Pujun, CHEN Chongyang, ZHANG Ying, et al. Characteristics of volcanic reservoirs and distribution rules of effective reservoirs in the Changling fault depression, Songliao basin[J]. Natural Gas Industry, 2015, 35(08):10-18. [6] 李万清,孙国军,丁东财,等. 长深区块深井防塌钻井液技术[J]. 钻井液与完井液,2007,25(2):70-72.LI Wanqing, SUN Guojun, DING Dongcai, et al. Inhibitive drilling fluid technology in deep well drilling in block Changshen[J]. Drilling Fluid & Completion Fluid, 2007, 25(2):70-72. [7] 冯京海,徐同台,王富华,等. 南堡油田馆陶组玄武岩井壁失稳机理和技术对策研讨[J]. 钻井液与完井液,2008,25(5):1-4.FENG Jinghai, XU Tongtai, WANG Fuhua, et al. Borehole wall sloughing of basalt rocks in guantao formation in Nanbao oilfield: mechanism and technological solution[J]. Drilling Fluid & Completion Fluid, 2008, 25(5):1-4. [8] 刘彦学. 松南气田低密度低伤害随钻堵漏钻井液技术[J]. 钻井液与完井液,2019,36(4):442-448.LIU Yanxue. Low damage low density drilling fluid used in Songnan gas filed for lost circulation control while drilling[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):442-448. [9] 刘翔,罗宇峰,王娟,等. 钻井液CO2污染的测试方法及处理技术[J]. 钻采工艺,2009,32(6):78-81.LIU Xiang, LUO Yufeng, WANG Juan, et al. Testing method and treating technology for CO2 pollution of drilling fluid[J]. Drilling & Production Technology, 2009, 32(6):78-81. [10] 王磊磊,王伟忠,张坤,等. 水基钻井液用抗高温降滤失剂的合成与性能评价[J]. 钻井液与完井液,2016,33(2):22-25.WANG Leilei, WANG Weizhong, ZHANG Kun, et al. Synthesis and evaluation of high temperature water base drilling fluid filter loss reducer[J]. Drilling Fluid & Completion Fluid, 2016, 33(2):22-25. [11] 毛惠,邱正松,付建国,等. 聚合物基纳米SiO2的制备及钻井液性能[J]. 中南大学学报(自然科学版),2015,46(7):2564-2570.MAO Hui, QIU Zhengsong, FU Jianguo, et al. Synthesis and drilling fluid performance of polymer based nano-silica composite[J]. Journal of Central South University (Science and Technology) , 2015, 46(7):2564-2570. [12] BERG PC, PEDERSEN ES, LAURITSEN A, et al. Drilling, completion and openhole formation evaluation of high-angle wells in high-density cesium formate brine: the kvitebjørn experience, 2004-2006, SPE 105733 2007. [13] 夏鹏,蔡记华,范志军,等. 纳米二氧化硅对盐水钻井液性能的影响[J]. 钻井液与完井液,2015,32(3):9-12.XIA Peng, CAI Jihua, FAN Zhijun, et al. Effect of nano SiO2 on performance of saltwater drilling fluid[J]. Drilling Fluid & Completion Fluid, 2015, 32(3):9-12. -

下载:

下载: