Field Application of a Plugging Borehole Wall Anti-Collapse Agent XZ-OSD in the Piedmont Structural Belt on the South Margin of Junggar Basin

-

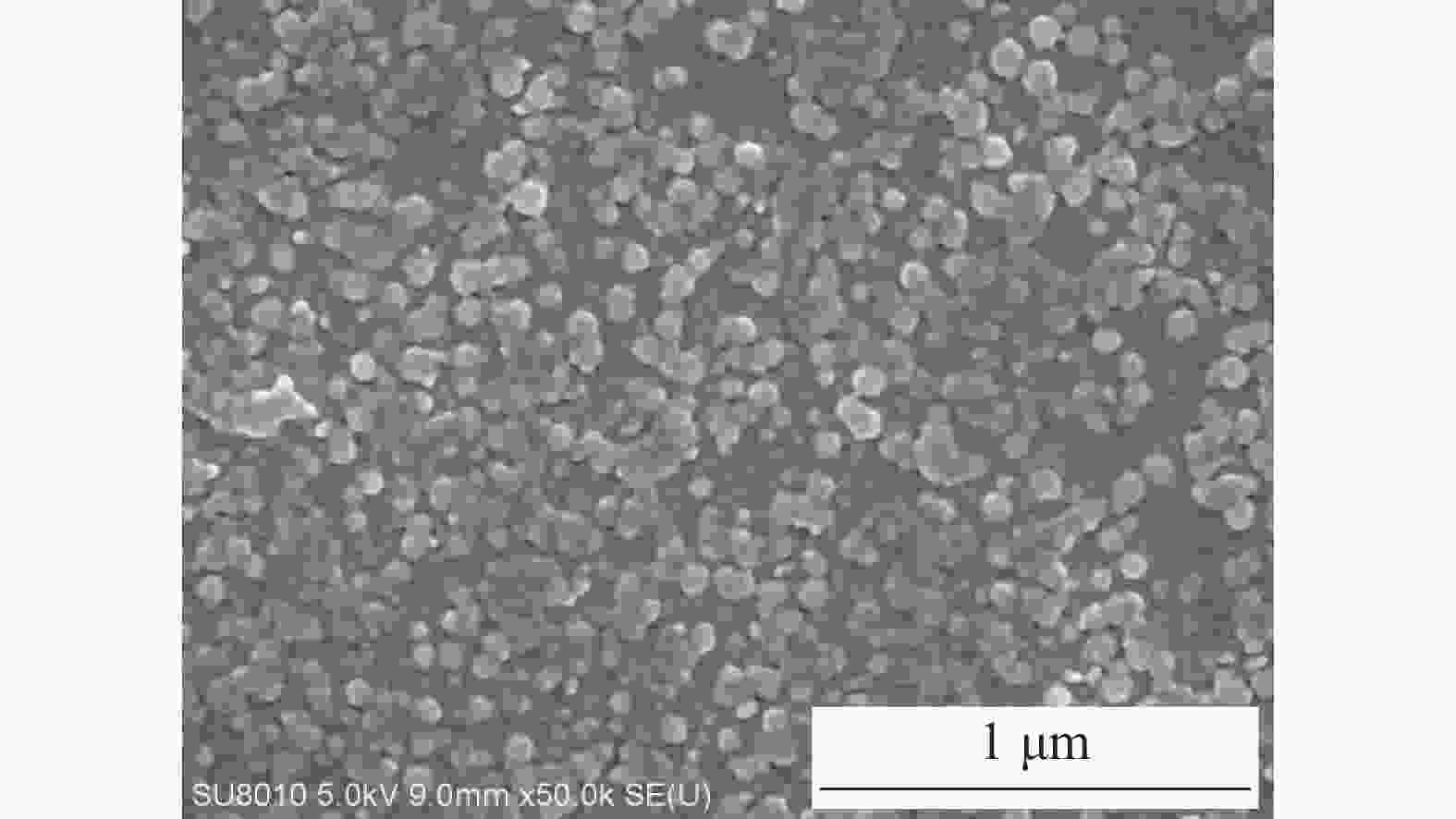

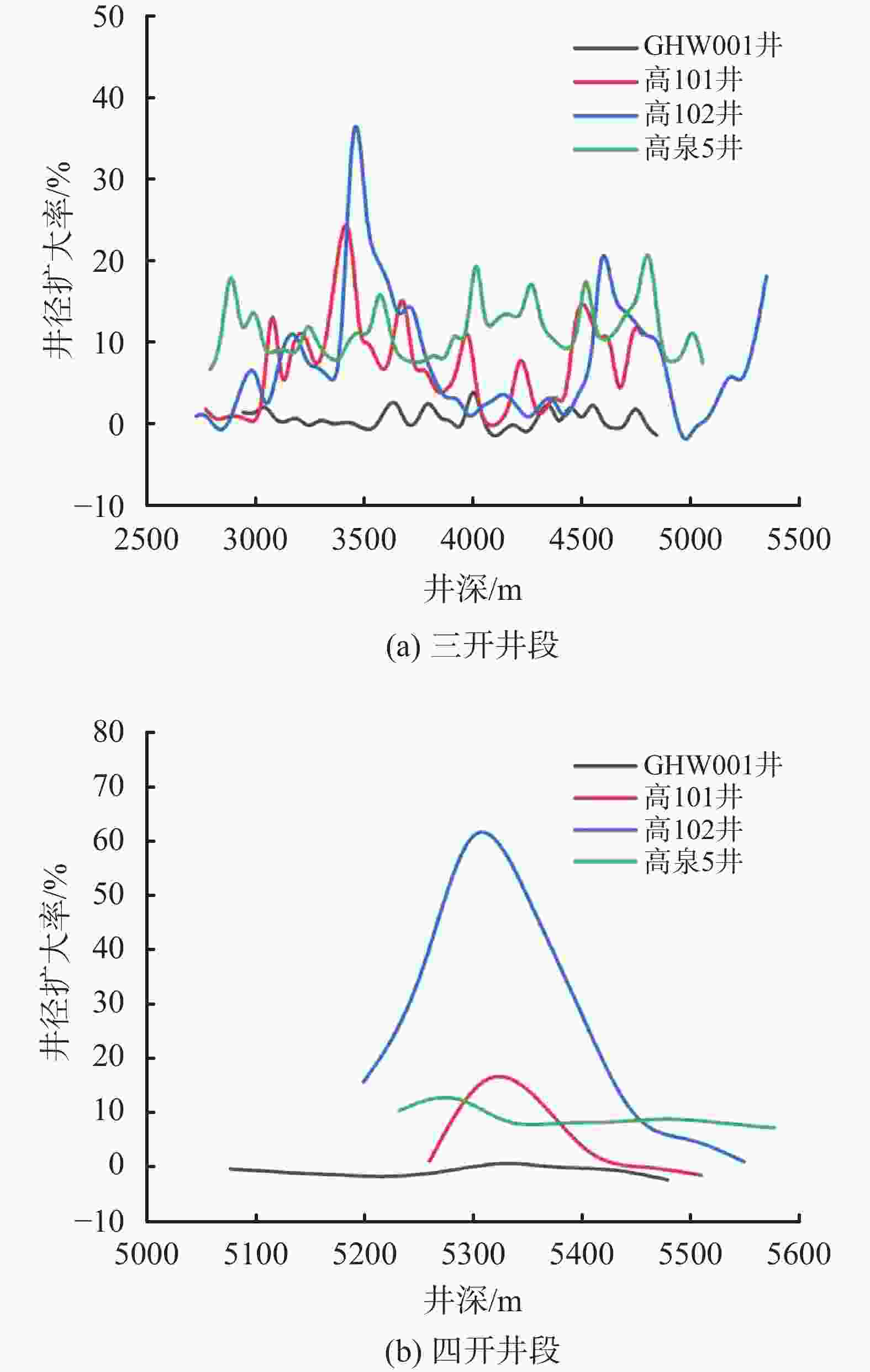

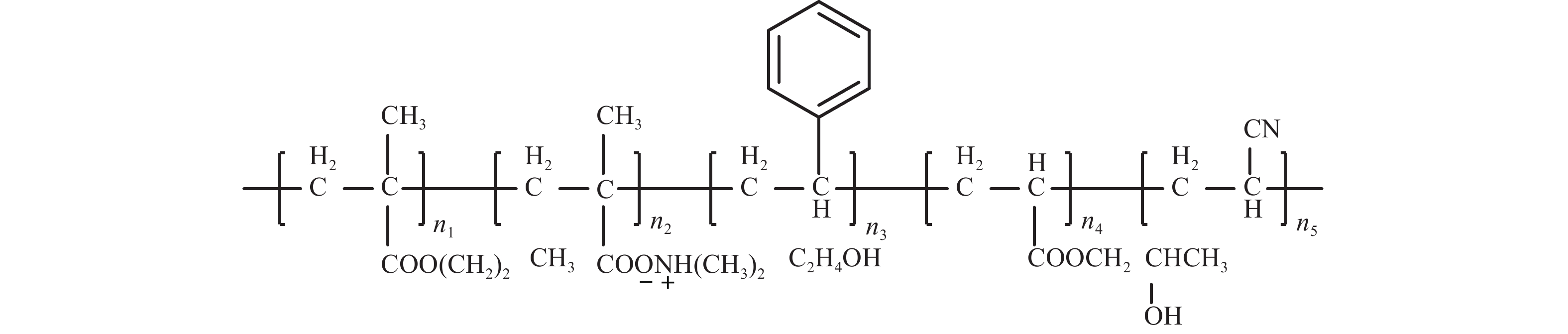

摘要: 为解决准噶尔盆地南缘山前构造带钻井过程中出现的井壁失稳及井漏问题,通过对目标地区的岩样和掉块进行实验分析,明确了目标地区的井壁失稳机理。根据实验结果知道,主要是地层破碎性、油相损害和强水敏性导致目的地区的井壁失稳。针对井壁失稳机理,采用油基钻井液避免地层强水敏性引起的井壁失稳,并研选了一种油基钻井液强封堵防塌剂XZ-OSD,XZ-OSD粒子通过封堵不同尺寸孔缝,胶结破碎性地层,在岩石表面形成疏油吸附层,避免地层破碎性、油相损害引起的井壁失稳。现场试验表明, 对比邻井,XZ-OSD降低GHW001三、四开阶段井径扩大率46%~49%;对比四开阶段,XZ-OSD降低呼探1井五开井段井径扩大率83.3%。解决了准噶尔盆地南缘地区井壁失稳难题,为该区域优质钻井提供了钻井液技术支撑。Abstract: Borehole wall collapse and mud losses have been occurring during drilling operation in the piedmont structural belt on the south margin of Junggar Basin. By experimentally analyzing the rock samples and drilled cuttings taken from the target drilling area, the borehole wall collapse mechanisms were understood. The experimental results show that borehole wall collapse results from the broken formations, oil phase damaging and strong water sensitivity of the formation rocks. Based on this knowledge, an oil based drilling fluid was chosen to drill the water sensitive formations, and XZ-OSD, a borehole wall anti-collapse preventing agent with strong plugging capacity, was selected for use in the oil based drilling fluid. XZ-OSD can plug pores of different sizes in the formations, bond the broken formations together, and form oleophobic adsorption layer on the surfaces of the rock, thereby preventing the borehole wall collapse caused by broken formations and oil phase damaging. Field application showed that, compared with the offset wells, the percent rate of hole enlargement of the 3rd and the 4th intervals of the well GHW001 was reduced by 46%-49%. In another well Hutan-1, an exploratory well, the percent rate of hole enlargement in the 5th interval, in which the mud was treated with XZ-OSD, was reduced by 83.3% compared with the 4th interval of the well. The use of XZ-OSD effectively solved the problem of borehole instability in the southern margin of the Junggar Basin, and provided drilling fluid technical support for high quality drilling in this area.

-

Key words:

- Borehole destabilization /

- Anti-collapse agent /

- Oil based drilling fluid /

- Junggar Basin

-

表 1 XZ-OSD对钻井液性能的影响

配方 实验 PV/

mPa·sYP/

PaGel/

Pa/PaES/

V井浆 热滚前 78 16.0 5.0/21.0 基浆 热滚前 50 9.0 3.0/16.0 1278 基浆+

3%XZ-OSD热滚前 52 9.5 3.0/17.0 1685 150 ℃、16 h 51 8.0 2.5/11.0 1902 150 ℃、72 h 51 6.5 2.0/10.0 2001 基浆+

5%XZ-OSD热滚前 61 11.5 3.5/17.0 1751 150 ℃、16 h 58 11.0 2.5/13.0 2047 150 ℃、72 h 55 10.0 2.0/11.0 2047 基浆+

10XZ-OSD热滚前 68 16.0 3.5/16.0 1885 150 ℃、16 h 71 11.5 3.0/14.0 2047 150 ℃、72 h 70 10.0 3.0/12.0 2047 注:井浆呼探1井的井浆(油水比为90∶10),基浆为呼探1井井浆+3#白油(井浆体积的10%)+3%主乳化剂+2%辅乳化剂 表 2 砂盘封堵测试结果

t/

min不同孔喉砂盘下的FLHTHP(mL)/承压(MPa) 20 μm 40 μm 55 μm 120 μm 150 μm 1.0 0.1/15 0.1/15 0.1/15 2.4/13.5 1.6/8.0 2.5 0.1/15 0.1/15 0.1/15 3.1/15.0 4.5/13.5 5.0 0.1/15 0.1/15 0.1/15 3.4/15.0 10.2/13.5 7.5 0.1/15 0.1/15 0.1/15 3.4/15.0 18.8/15.0 15.0 0.1/15 0.1/15 0.1/15 3.4/15.0 20.2/15.0 25.0 0.1/15 0.1/15 0.1/15 3.4/15.0 20.9/15.0 30.0 0.1/15 0.1/15 0.1/15 3.4/15.0 21.1/15.0 40.0 0.1/15 0.1/15 0.1/15 3.4/15.0 23.0/15.0 50.0 0.1/15 0.1/15 0.1/15 3.4/15.0 25.9/15.0 60.0 0.1/15 0.2/15 0.2/15 3.4/15.0 26.8/15.0 注:热滚条件为100 ℃、16 h,FLHTHP在100 ℃测定 表 3 各井三开、四开井径扩大率对比

井号 三开平均

井径/mm三开平均井径

扩大率/%四开平均

井径/mm四开平均井径

扩大率/%GHW001 450.72 1.38 316.10 1.57 高101 312.75 4.50 225.88 4.62 高102 344.76 10.78 217.92 2.94 高泉5 340.02 9.26 244.20 13.10 -

[1] 辜延容. 准噶尔盆地南缘构造特征与油气分布 [D].成都理工大学, 2015.GU Yanrong. The structural feature and oil-gas distribution in the southern margin of Junggar basin [D]. Chengdu University of Technology, 2015. [2] 张雄,余进,毛俊,等. 准噶尔盆地玛东油田水平井高性能油基钻井液技术[J]. 石油钻探技术,2020,48(6):21-27.ZHANG Xiong, YU Jin, MAO Jun, et al. High-performance oil-based drilling fluid technology for horizontal wells in the Madong Oilfield, Junggar Basin[J]. Petroleum Drilling Technology, 2020, 48(6):21-27. [3] 景丰,姚志奇. 延长组页岩气水平井水基钻井液体系研制与应用[J]. 大庆石油地质与开发,2019,38(6):155-161.JING Feng, YAO Zhiqi. Development and application of water-based drilling fluid system in Yanchang Formation shale-gas horizontal wells[J]. Daqing Petroleum Geology and Development, 2019, 38(6):155-161. [4] 康毅力,许成元,唐龙,等. 构筑井周坚韧屏障: 井漏控制理论与方法[J]. 石油勘探与开发,2014,41(4):473-479.KANG Yili, XU Chengyuan, TANG Long, et al. Constructing a tough shield around the wellbore: Theory and method for lost-circulation control[J]. Petroleum Exploration and Development, 2014, 41(4):473-479. [5] ALKINANI H H, AL-HAMEEDI A T T, DUNN-NORMAN S, et al. Using data mining to stop or mitigate lost circulation[J]. Journal of Petroleum Science and Engineering, 2019, 173:1097-1108. [6] 宋碧涛,马成云,徐同台,等. 硬脆性泥页岩钻井液封堵性评价方法[J]. 钻井液与完井液,2016,33(4):51-55.SONG Bitao, MA Chengyun, XU Tongtai, et al. Method for evaluating the performance of drilling fluids plugging fractures in hard and brittle shale[J]. Drilling Fluid & Completion Fluid, 2016, 33(4):51-55. [7] 吴继伟,张晨,黄鸿,等. 准噶尔盆地南缘超深井扩眼尺寸优选方法[J]. 新疆石油天然气,2020,16(3):33-37.WU Jiwei, ZHANG Chen, HUANG Hong, et al. Reaming-ole size optimizing method for ultra-deep wells in southern margin of Junggar basin[J]. Xinjiang Oil & Gas, 2020, 16(3):33-37. [8] 张凤奇,鲁雪松,卓勤功,等. 准噶尔盆地南缘下组合储层异常高压成因机制及演化特征[J]. 石油与天然气地质,2020,41(5):1004-1016.ZHANG Fengqi, LU Xuesong, ZHUO Qingong, et al. Genetic mechanism and evolution characteristics of overpressure in the lower play at the southern margin of Junggar basin, northwestern China[J]. Oil & Gas Geology, 2020, 41(5):1004-1016. [9] PEI Z, QIAN-DING L I, HUI L I, et al. Advances in development of expandible lost circulation materials[J]. Oilfield Chemistry, 2009, 26(1):111-114. -

下载:

下载: