An Anti-Collapse Drilling Fluid with Strong Inhibitive and Plugging Capacity for Use in the Fuxian Block in Ordos Basin

-

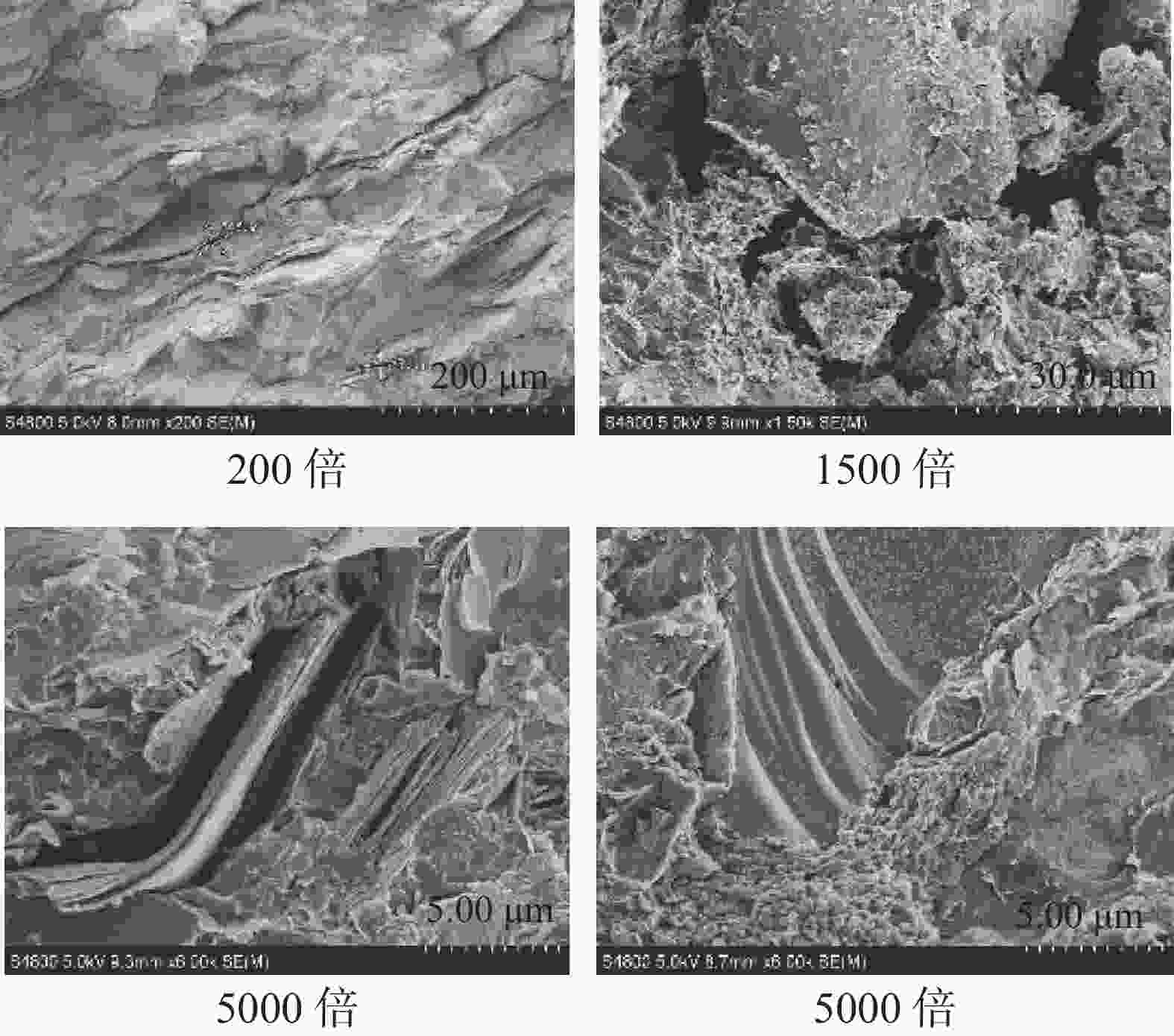

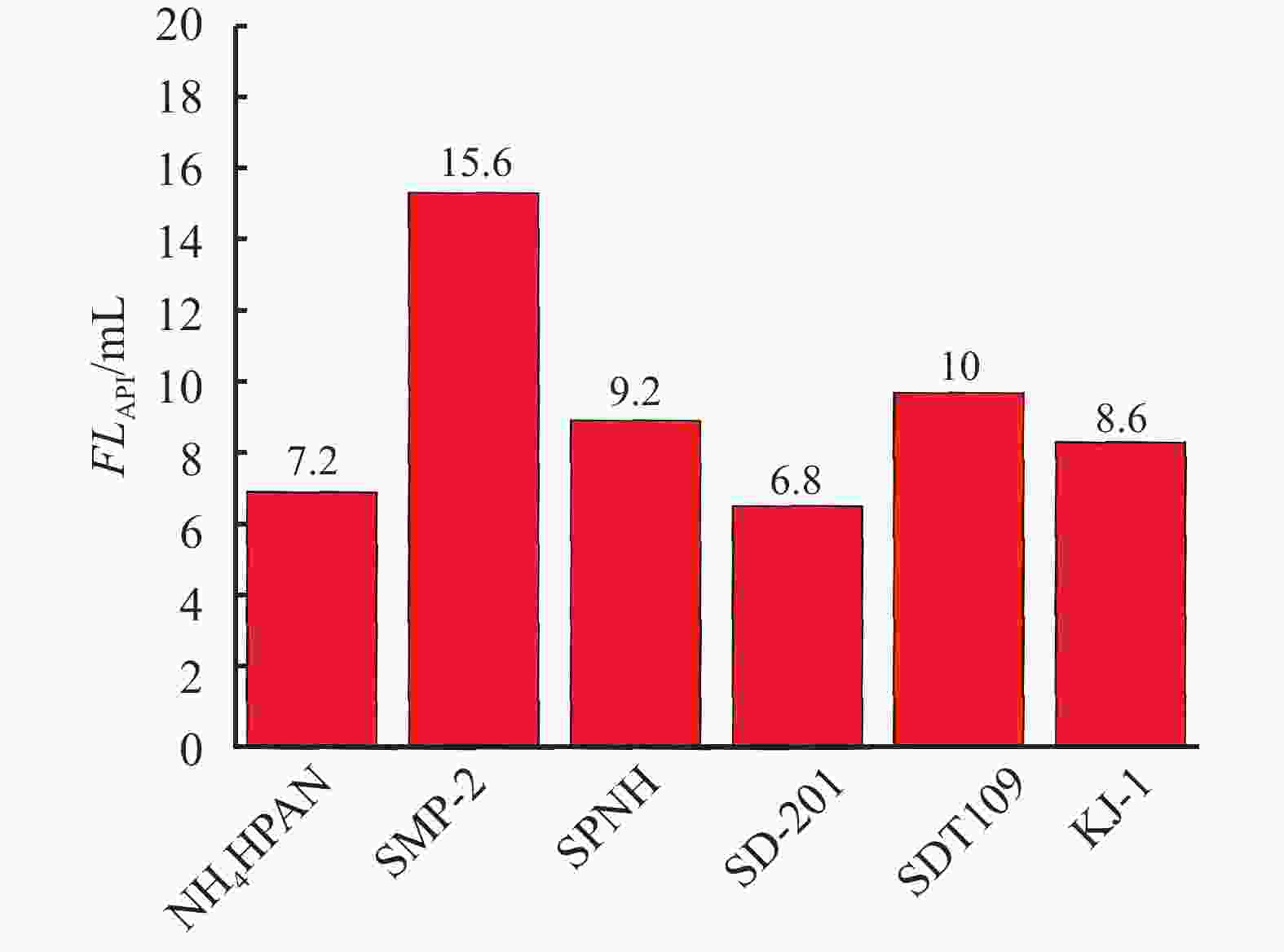

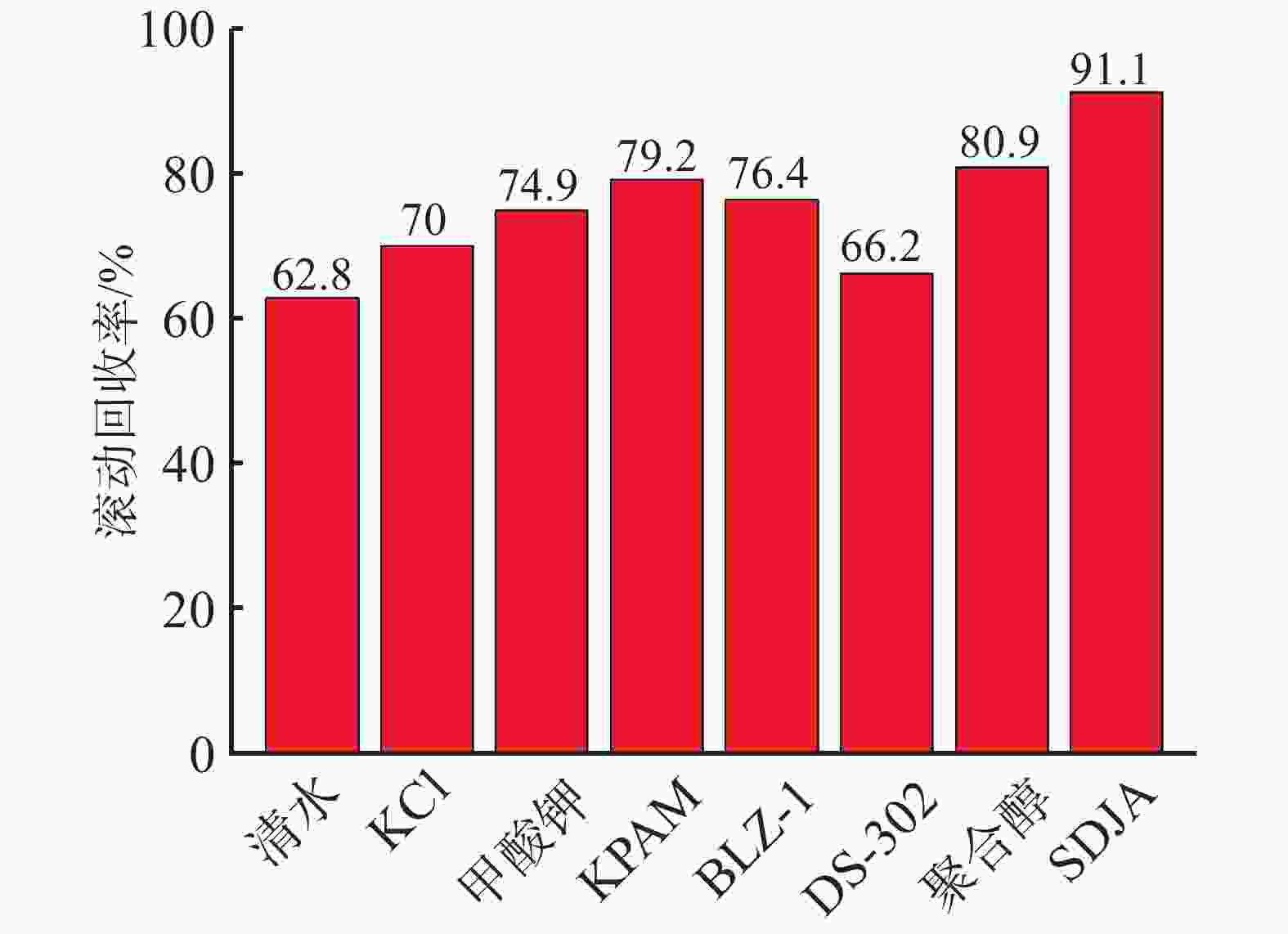

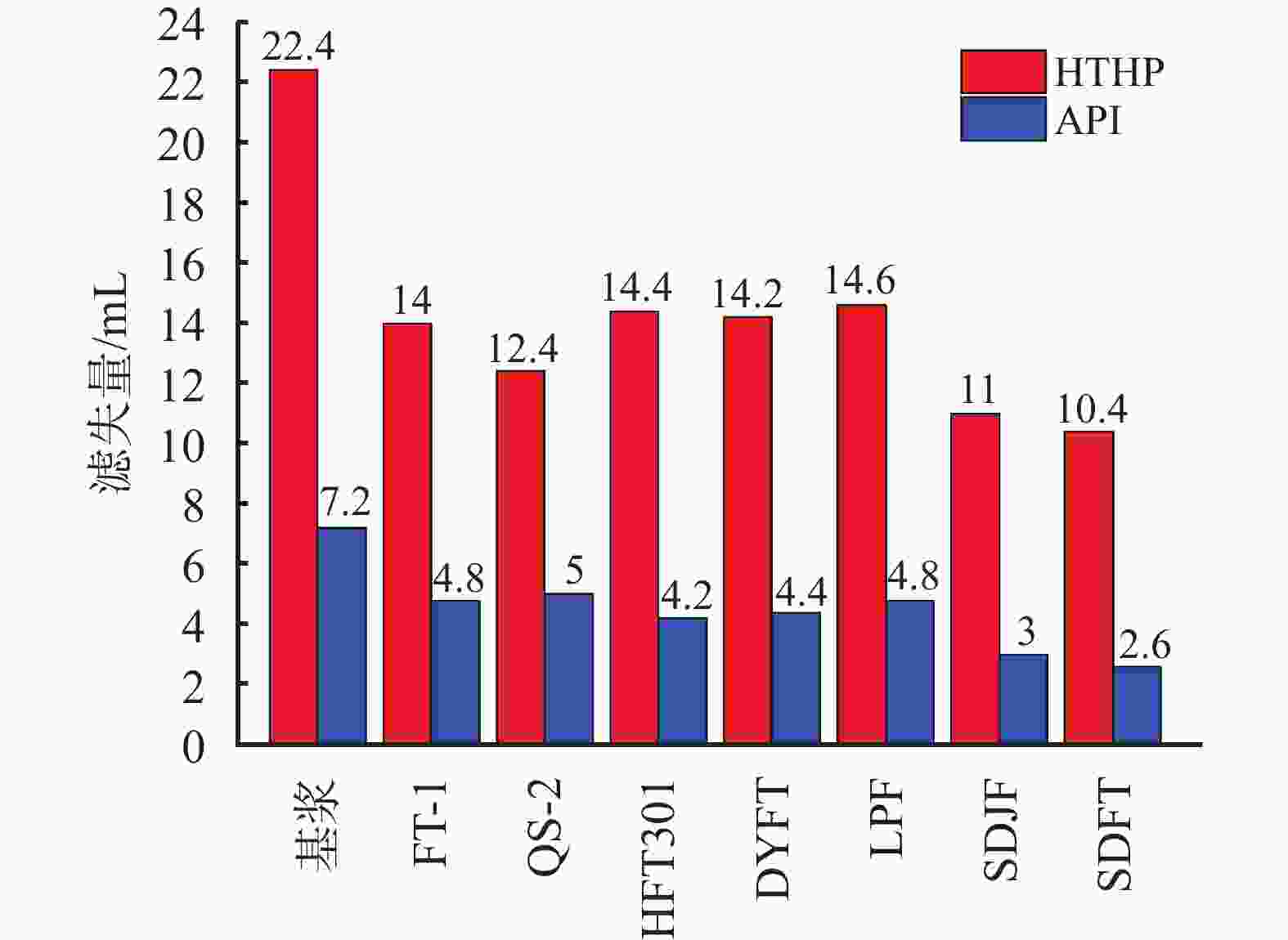

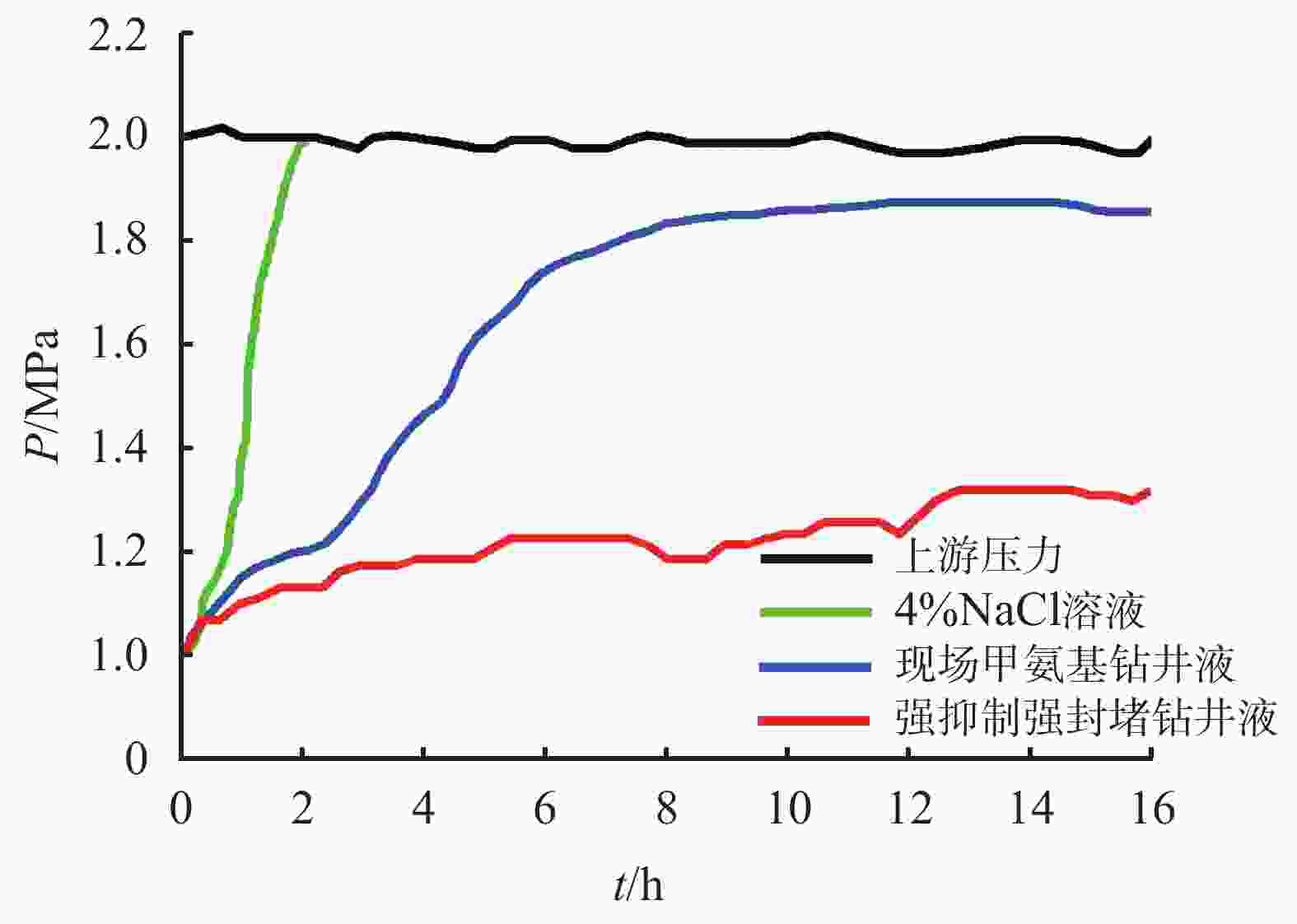

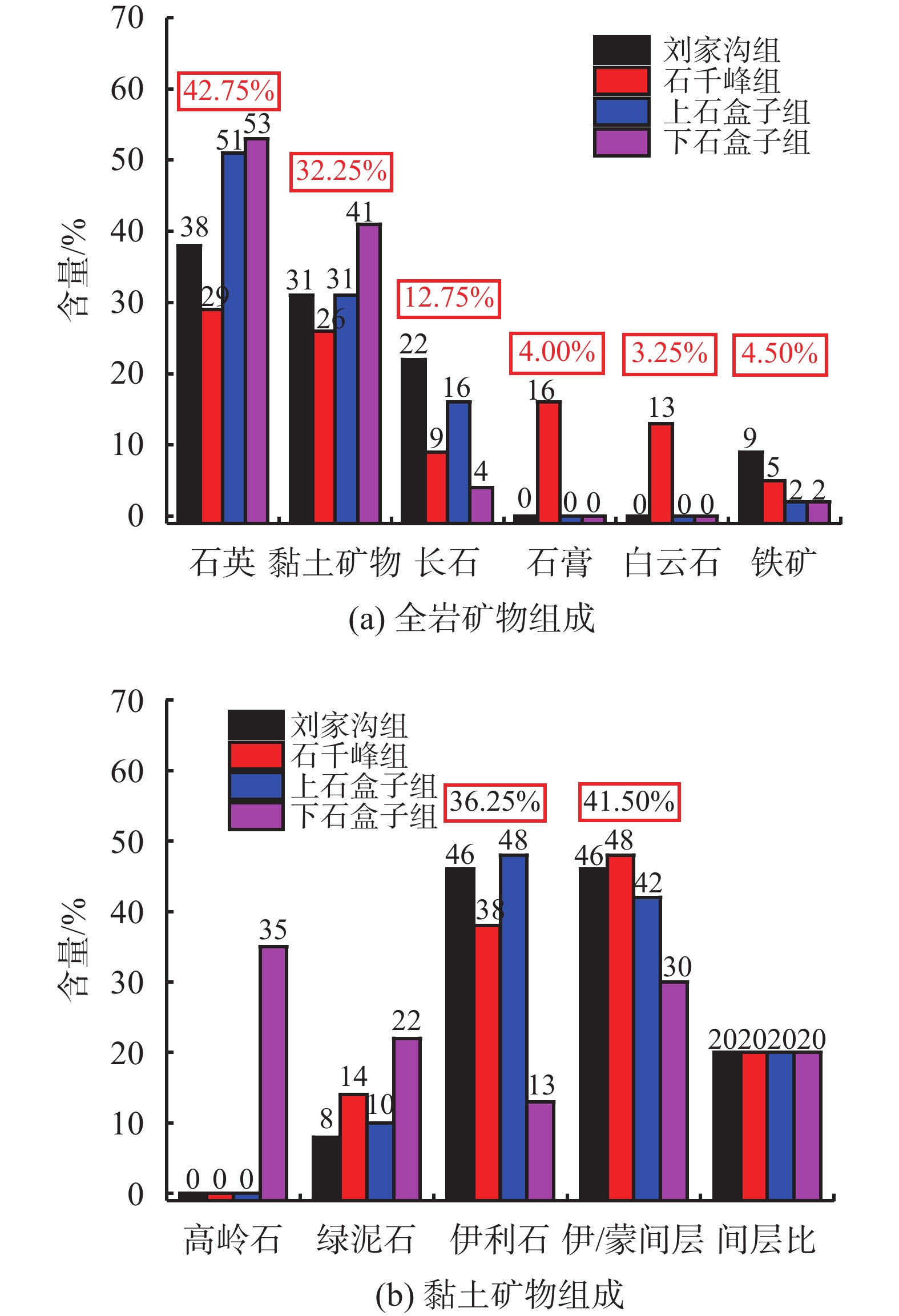

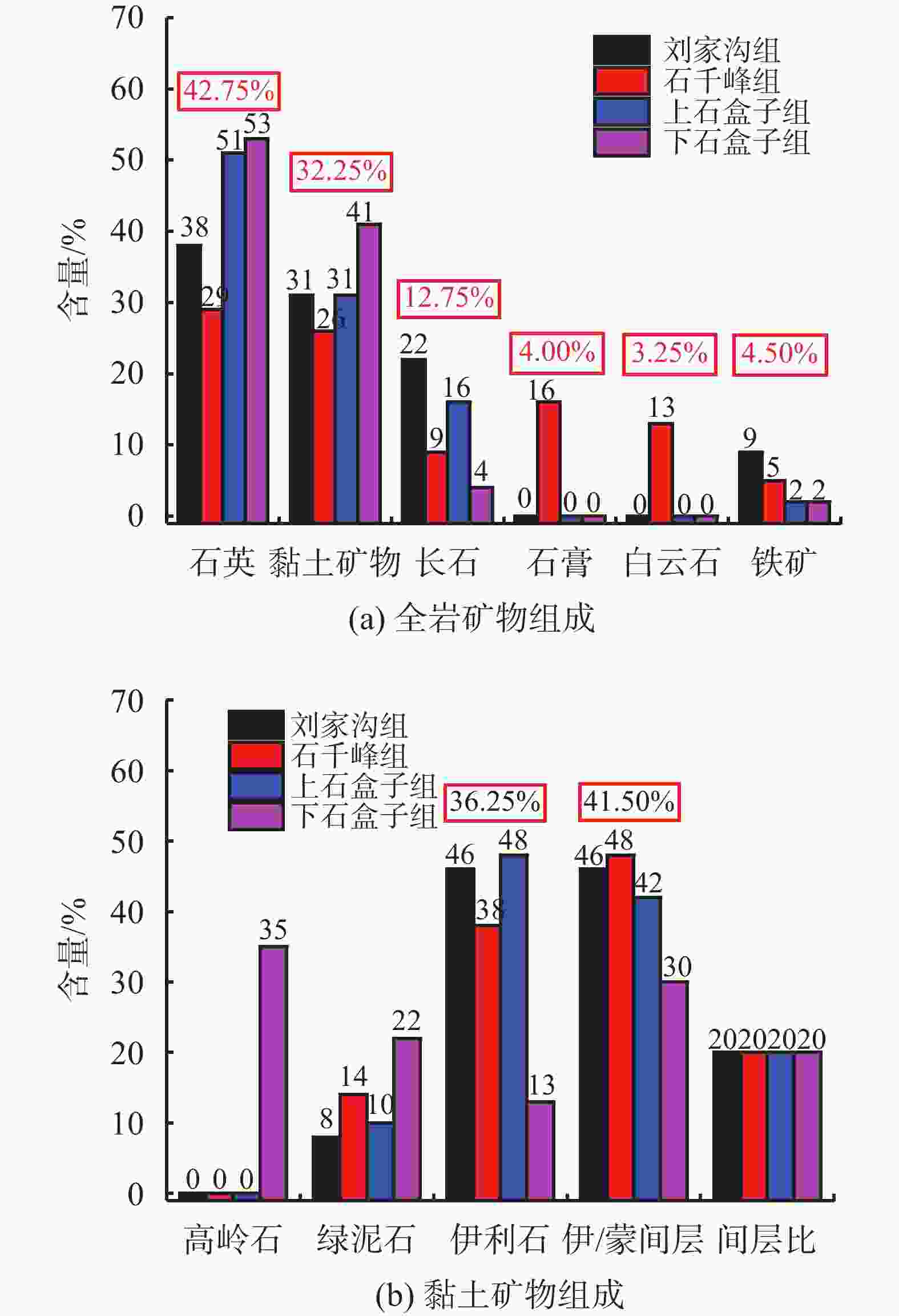

摘要: 针对鄂尔多斯盆地富县区块井壁失稳技术难题,从复杂地层的矿物组成、微观结构和理化性能角度,揭示了富县区块刘家沟组、石千峰组和石盒子组井壁失稳机理。泥岩中黏土含量较高,地层孔隙、裂缝发育,为泥页岩水化提供了空间。结合“多元协同”井壁稳定理论,提出“物化封堵/固结井壁阻缓压力传递—加强抑制黏土水化性能—合理密度支撑井壁”的防塌钻井液技术对策。通过单剂优选和配方优化,构建了适用于富县区块的强抑制强封堵防塌钻井液体系,该钻井液体系流变性良好,高温高压滤失量仅为8.4 mL,抑制防塌、封堵能力强,滚动回收率大于90%,400 μm裂缝承压能力达到6 MPa,储层保护性能良好。现场应用表明,新研制的强抑制强封堵钻井液体系能有效控制刘家沟组、石千峰组和石盒子组等地层的缩径、坍塌,显著降低了井径扩大率,提高了机械钻速,无井下复杂事故发生,为保证富县区块“安全、高效”的钻井施工提供了钻井液技术保障。Abstract: Borehole wall instability was encountered in drilling the Liujiagou formation, the Shiqianfeng formation and the Shihezi formation in the Fuxian block, and the mechanisms of the instability were investigated and revealed through studies on three aspects, namely, the mineral composition, microstructure and physio-chemical property of the formations in question. These studies are aimed at solving the borehole wall sloughing problem encountered in the drilling operation in the Fuxian block in Ordos Basin, in which the shale contains high content of clays and is developed with pores and fractures resulting in shale hydration. Based on the “synergy of multiple factors” theory, a technical measure for stabilizing borehole wall, which can be described as “physio-chemically plugging/consolidating borehole wall to retard pressure transmission-strengthening the inhibition of clay hydration-supporting the borehole wall with appropriate mud weight”, was presented. A drilling fluid with strong inhibitive capacity and plugging capacity was formulated based on the optimization of each additive in and the whole composition of the drilling fluid to deal with the sloughing of the borehole wall. The drilling fluid has HTHP filtration rate of 8.4 mL, strong inhibitive and plugging capacity, and percent recovery of shale cuttings of 90% in hot rolling test. Plugging of 400 μm fractures with the drilling fluid renders the formation in which these fractures exist a pressure bearing capacity of 6 MPa. The drilling fluid also has good reservoir protection capacity. Field application shows that this new drilling fluid is able to effectively mitigate the tight hole and sloughing, reduce the rate of hole enlargement, and increase rate of penetration. Using this drilling fluid, no downhole troubles have ever happened, providing drilling fluid technical support to the safe and efficient drilling in the Fuxian block.

-

表 1 富县区块复杂地层泥页岩水化分散/膨胀实验

深度/m 层位 清水滚动

回收率/%清水16 h

膨胀率/%2482~2484 刘家沟组 82.4 12.6 2680~2682 石千峰组 86.1 10.7 2540~2540 石千峰组 72.6 13.4 3032~3034 石盒子组 82.9 11.8 2792~2794 石盒子组 62.8 15.7 表 2 旬宜1井泥页岩阳离子交换容量实验

井深/m 层位 CEC/

mmol/kgMBT/

g/kg2792~2794 石千峰组和上石盒子组交界处 35 50.00 3022~3024 下石盒子组和山西组交界处 40 57.14 表 3 强抑制强封堵防塌钻井液流变性能及滤失性能

条件 AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLHK/

mmFLHTHP/

mL老化前 36 26 10 1.5/8 3.2 0.5 8.4 老化后 32 21 11 1.0/6 3.0 0.5 表 4 强抑制强封堵防塌钻井液的抑制性能评价

钻井液 滚动回收率/% 16 h膨胀率/% 清水 62.8 15.7 现场钾铵基 78.2 8.2 强抑制强封堵防塌 94.2 3.2 表 5 强抑制强封堵防塌钻井液对裂缝封堵性能评价

裂缝开

度/μm承压时

间/minP/

MPa累积漏失

量/mL封堵情况描述 400 10 6.0 45 加压至0.5 MPa漏失15 mL,加加压至2.0 MPa,漏失45 mL,加压至6.0 MPa,承压10 min仍无漏失发生。 表 6 强抑制强封堵防塌钻井液污染后山西组岩心的渗透率

深度/

mKo/

mDKd/

mDKd/ Ko/% 切除前 切除1 cm 切除2 cm 3064~

30730.012 32 0.008 96 72.73 94.48 96.62 3125.73~

3127.420.003 86 0.003 18 82.38 88.60 93.48 -

[1] 汤志川,邱正松,钟汉毅,等. 新型壳聚糖-邻苯二酚化学固壁剂合成与性能评价[J]. 钻井液与完井液,2019,36(5):534-541. doi: 10.3969/j.issn.1001-5620.2019.05.002TANG Zhichuan, QIU Zhengsong, ZHONG Hanyi, et al. Synthesis and evaluation of a new chemical borehole wall strengthener made from chitosan-catechol[J]. Drilling Fluid & Completion Fluid, 2019, 36(5):534-541. doi: 10.3969/j.issn.1001-5620.2019.05.002 [2] 王伟吉. 页岩气地层水基防塌钻井液技术研究[D]. 中国石油大学(华东), 2017.WANG Weiji. Study on water-based anti-sloughing drilling fluid technology for shale gas formation[D]. Dongying: China University of Petroleum (East China), 2017. [3] 邱正松,徐加放,吕开河,等. "多元协同"稳定井壁新理论[J]. 石油学报,2007,28(2):117-119. doi: 10.3321/j.issn:0253-2697.2007.02.024QIU Zhengsong, XU Jiafang, LYU Kaihe, et al. A multivariate cooperation principle for well-bore stabilization[J]. Acta Petrolei Sinica, 2007, 28(2):117-119. doi: 10.3321/j.issn:0253-2697.2007.02.024 [4] 李成,白杨,于洋,等. 顺北油田破碎地层井壁稳定钻井液技术[J]. 钻井液与完井液,2020,37(1):15-22.LI Cheng, BAI Yang, YU Yang, et al. Study and application of drilling fluid technology for stabilizing fractured formations in Shunbei oilfield[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):15-22. [5] 于成旺,杨淑君,赵素娟. 页岩气井钻井液井眼强化技术[J]. 钻井液与完井液,2018,35(6):49-54. doi: 10.3969/j.issn.1001-5620.2018.06.009YU Chengwang, YANG Shujun, ZHAO Sujuan. Borehole wall strengthening with drilling fluids in shale gas drilling[J]. Drilling Fluid & Completion Fluid, 2018, 35(6):49-54. doi: 10.3969/j.issn.1001-5620.2018.06.009 [6] 唐文泉,高书阳,王成彪,等. 龙马溪页岩井壁失稳机理及高性能水基钻井液技术[J]. 钻井液与完井液,2017,34(3):21-26. doi: 10.3969/j.issn.1001-5620.2017.03.004TANG Wenquan, GAO Shuyang, WANG Chengbiao, et al. Research on mechanisms of wellbore instability of longmaxi shale formation and high performance water base drilling fluid technology[J]. Drilling Fluid & Completion Fluid, 2017, 34(3):21-26. doi: 10.3969/j.issn.1001-5620.2017.03.004 [7] 赵欣,邱正松,张永君,等. 复合盐层井壁失稳机理及防塌钻井液技术[J]. 中南大学学报(自然科学版),2016,47(11):3832-3838.ZHAO Xin, QIU Zhengsong, ZHANG Yongjun, et al. Wellbore instability mechanism and wellbore stabilizing drilling fluid technique for drilling compound salt formation[J]. Journal of Central South University (Science and Technology) , 2016, 47(11):3832-3838. [8] 王艳. 多元协同井壁稳定水基钻井液研究[D].成都: 西南石油大学, 2016.WANG Yan. Study on water-based drilling fluid with multiple synergy well-bore stability[D].Chenhdu: Southwest Petroleum University, 2016. [9] 黄维安,牛晓,沈青云,等. 塔河油田深侧钻井防塌钻井液技术[J]. 石油钻探技术,2016,44(2):51-57.HUANG Weian, NIU Xiao, SHEN Qingyun, et al. Anti-sloughing drilling fluid technology for deep sidetracking wells in the Tahe Oilfield[J]. Petroleum Drilling Techniques, 2016, 44(2):51-57. [10] 王富华,邱正松,王瑞和. 保护油气层的防塌钻井液技术研究[J]. 钻井液与完井液,2004,21(4):50-53.WANG Fuhua, QIU Zhengsong, WANG Ruihe. Study on anti-sloughing drilling fluid technology for oil and gas reservoir protection[J]. Drilling Fluid & Completion Fluid, 2004, 21(4):50-53. [11] 钟汉毅,邱正松,黄维安,等. 聚胺高性能水基钻井液特性评价及应用[J]. 科学技术与工程,2013,13(10):2803-2807. doi: 10.3969/j.issn.1671-1815.2013.10.036ZHONG Hanyi, QIU Zhengsong, HUANG Weian, et al. Properties evaluation and application of polyamine high performance water-based drilling fluid[J]. Science Technology and Engineering, 2013, 13(10):2803-2807. doi: 10.3969/j.issn.1671-1815.2013.10.036 [12] 钟汉毅,黄维安,林永学,等. 新型聚胺页岩抑制剂性能评价[J]. 石油钻探技术,2011,39(6):44-48. doi: 10.3969/j.issn.1001-0890.2011.06.011ZHONG Hanyi, HUANG Weian, LIN Yongxue, et al. Properties Evaluation of a noval polyamine shale inhibitor[J]. Petroleum Drilling Techniques, 2011, 39(6):44-48. doi: 10.3969/j.issn.1001-0890.2011.06.011 [13] 邱正松,钟汉毅,黄维安. 新型聚胺页岩抑制剂特性及作用机理[J]. 石油学报,2011,32(4):678-682.QIU Zhengsong, ZHONG Hanyi, HUANG Weian. Properties and mechanism of a new polyamine shale inhibitor[J]. Acta Petrolei Sinica, 2011, 32(4):678-682. [14] 张坤, 王磊磊, 董殿彬,等. 多元聚胺钻井液研究与应用[J]. 钻井液与完井液, 2020, 37(3): 301-305.ZHANG Kun, WANG Llei lei, DONG Danbin, et al. Study on and application of a polyamine drilling fluid[J]. Drilling Fluid & Completion Fluid, 2020, 37(3): 301-305. [15] 罗健生,蒋官澄,王国帅,等. 一种无氯盐环保型强抑制水基钻井液体系[J]. 钻井液与完井液,2019,36(5):594-599. doi: 10.3969/j.issn.1001-5620.2019.05.012LUO Jiansheng, JIANG Guancheng, WANG Guoshuai, et al. Development of an environmentally friendly strongly inhibitive chloride-free water base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(5):594-599. doi: 10.3969/j.issn.1001-5620.2019.05.012 -

下载:

下载: