Drilling Fluid Technology for Plugging and Strengthening Formations with Narrow Mud Weight Windows in Deep Water Drilling

-

摘要: 针对深水地层压实程度低、钻井液安全密度窗口窄、易导致井漏的技术难题,以烯类单体、大分子交联剂及层状结构硅酸盐矿物等为主要原料制备了柔性颗粒封堵剂,以此为基础构建了深水抗高温封堵承压水基钻井液。室内实验证明,柔性颗粒封堵剂韧性好,抗温达160 ℃,在10%盐水中性能稳定,对渗透性岩心、裂缝及砂床均具有良好的封堵效果,显著提高承压能力;构建的深水抗高温封堵承压钻井液160 ℃老化前后流变性能稳定,黏度和切力合适,4 ℃与25 ℃下的动切力比值小于1.35,具有显著的低温恒流变特性,封堵后岩心的渗透率接近于零,承压能力达11 MPa,抗膨润土粉及氯化钠污染的能力强,保护储层效果良好,岩心渗透率恢复率大于90%。该深水抗高温封堵承压水基钻井液在南海陵水区块进行了现场应用,提高了易漏地层的承压能力,承压能力提高6~11 MPa,确保了复杂井段的钻井安全。Abstract: Formations drilled in deep water drilling are generally poorly compacted and have narrow safe mud weight windows, and mud losses in drilling these formations hence occur frequently. To solve these problems, a flexible particle plugging agent was developed with vinyl monomers, a macromolecular crosslinking agent and a silicate mineral with layered structure. Laboratory experimental results show that this flexible particle plugging agent has good toughness, and functions normally at temperatures as high as 160 ℃. In 10% salt water, the plugging agent has stable characteristics and can effectively plug permeable cores, fractures and sand-bed, significantly increasing their pressure bearing capacity. A high temperature drilling fluid for deep water drilling was treated with this plugging agent, and its properties before and after aging at 160 ℃ were stable. This drilling fluid has proper viscosity and gel strengths, and the ratio of the yield points at 4 ℃ and 25 ℃ is less than 1.35, indicating that the drilling fluid has constant rheology at low temperatures. Cores plugged with this drilling fluid have permeability that is near zero, and the pressure bearing capacity of the cores is 11 MPa. This drilling fluid has strong resistance to the contamination by clays and salt, and is of low damage to the permeability of reservoir formations; permeability recovery of plugged cores is at least 90%. The application of this drilling fluid in the Lingshui block in South China Sea effectively increased the pressure bearing capacity by 6-11 MPa, ensuring the safe drilling operation in the complex hole sections.

-

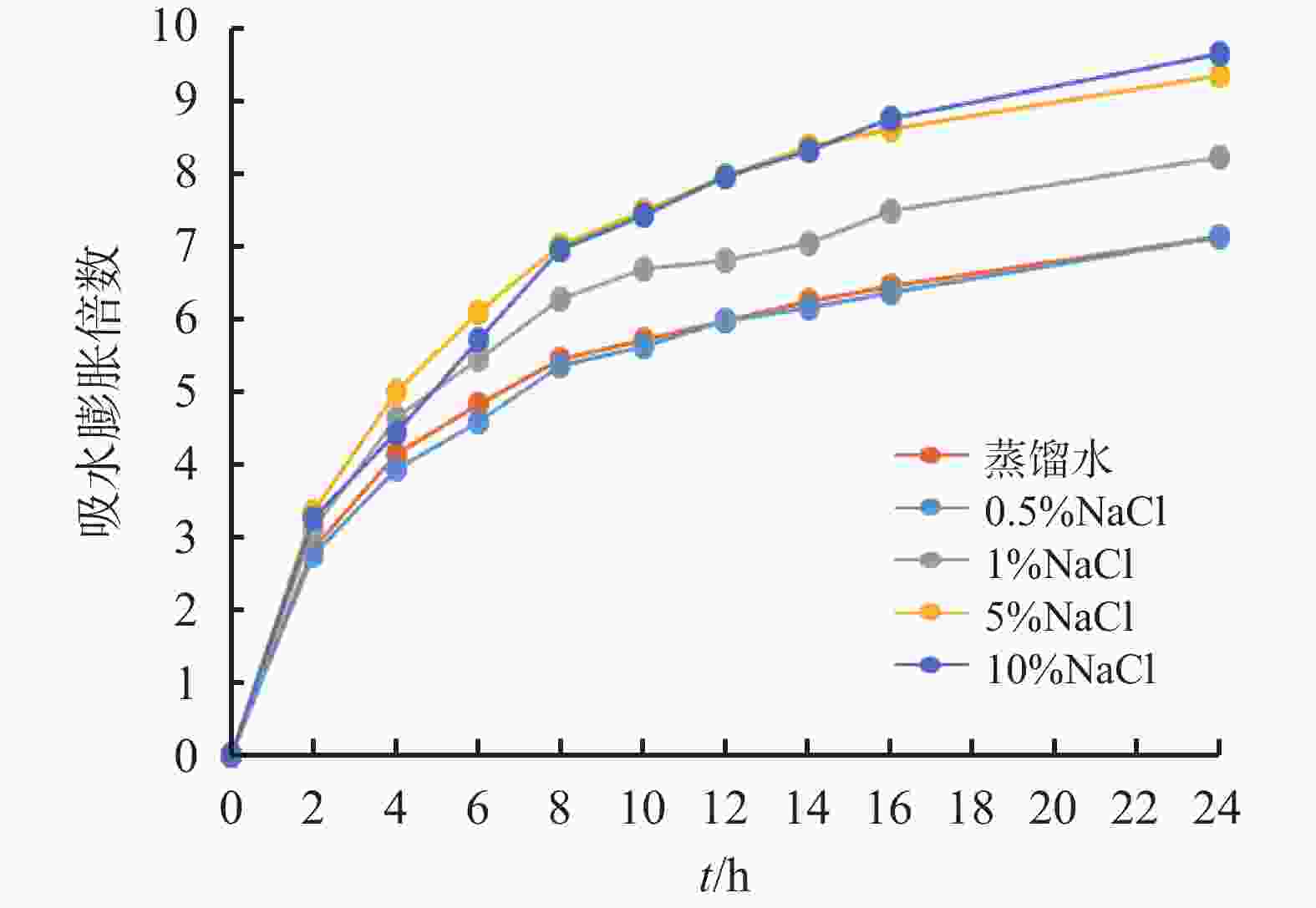

表 1 柔性颗粒封堵剂在不同温度下24 h的吸水膨胀倍数及拉伸倍数

T/℃ 吸水膨胀倍数/(g/g) 拉伸倍数 室温 7.10 4.9 50 7.32 4.8 75 7.64 4.6 100 8.27 4.5 125 8.31 4.5 150 8.83 4.3 160 9.05 4.3 170 6.15 2.6 表 2 加有封堵剂的聚合物井浆对渗透性岩心的封堵承压效果

K岩心/

D封堵剂 承压能力/

MPaFL/

mL0.75 空白 5.22 8.5 2%复合承压封堵剂 7.34 2.1 1%柔性颗粒封堵剂 10.03 1.5 2%柔性颗粒封堵剂 13.26 1.0 1.35 空白 4.55 13.0 2%复合承压封堵剂 6.83 3.8 1%柔性颗粒封堵剂 9.51 2.4 2%柔性颗粒封堵剂 12.01 1.8 表 3 加有封堵剂的聚合物井浆对裂缝的封堵承压效果

封堵剂 裂缝宽度/

mmFL/

mL承压能力/

MPa空白 1 135.6 5.34 1%柔性颗粒封堵剂 1 20.5 8.81 2%柔性颗粒封堵剂 1 12.6 10.32 2%复合承压封堵剂 1 37.4 6.78 1%柔性颗粒封堵剂 2 26.4 7.71 2%柔性颗粒封堵剂 2 19.7 8.93 2%复合承压封堵剂 2 50.2 6.35 1%柔性颗粒封堵剂 3 33.8 7.37 2%柔性颗粒封堵剂 3 24.5 8.21 2%复合承压封堵剂 3 89.3 5.22 表 4 在聚合物井浆中加入不同封堵剂对砂床的封堵效果

封堵剂 砂床侵入深度/cm 10~20目 20~40目 40~60目 0 全漏 13.6 8.2 1%柔性颗粒封堵剂 8.5 6.7 5.2 2%柔性颗粒封堵剂 7.8 5.5 4.3 2%复合承压封堵剂 12.1 8.8 7.5 表 5 柔性颗粒封堵剂对聚合物井浆性能的影响

柔性颗粒封堵剂/

%AV /

mPa·sPV /

mPa·sYP /

PaFL API/

mL0 33.0 25.5 8.5 4.5 1 38.0 29.0 9.0 4.2 2 45.0 34.5 10.5 4.1 表 6 抗高温封堵承压水基钻井液的流变及滤失性能

实验

条件T/

℃AV/

mPa·sPV/

mPa·sYP/

PaYP/PV/

Pa/ mPa·sFLAPI/

mLFLHTHP/

mL热滚前 25 30.5 20.0 10.5 0.53 4.2 11.2 10 32.0 21 11.0 0.52 4.2 4 39.0 26.0 13.0 0.50 4.1 热滚后 25 29.0 19.5 9.5 0.49 4.5 12.6 10 31.5 21.0 10.5 0.50 4.4 4 38.0 25.5 12.5 0.49 4.4 注:热滚条件为160 ℃、16 h,FLHTHP 在160 ℃、3.5 MPa下测定 表 7 深水抗高温封堵承压水基钻井液的封堵承压性能

岩心孔隙

度/%岩心渗

透率/mD封堵后岩心在不同驱替

压力下的渗透率/mD3.5 MPa 5 MPa 8 MPa 11 MPa 21.2 312.2 0.081 0.018 0.006 0.000 23.3 442.5 0.132 0.036 0.008 0.002 23.7 572.2 0.102 0.024 0.003 0.000 25.2 889.4 0.076 0.005 0.003 0.001 26.5 1121.3 0.118 0.023 0.007 0.001 表 8 优选水基钻井液的抗岩屑污染性能

污染条件 AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mLFLHTHP/

mL0 30.5 20.0 10.5 4.2 11.2 3%土粉 32.0 21.0 11.0 4.2 11.3 6%土粉 34.5 23.0 11.5 4.3 11.3 9%土粉 37.0 15.5 11.5 4.5 11.5 4%NaCl 33.5 22.0 11.5 4.5 12.1 10%NaCl 34.5 23.0 12.5 4.8 13.5 表 9 深水抗高温封堵承压水基钻井液的储层保护效果

岩心号 Ka/

mDK0 /

mDKd /

mD渗透率恢复率/

%1 637.2 108.5 101.3 93.4 2 405.8 86.4 77.9 90.2 3 210.2 54.3 49.7 91.5 -

[1] CLOSE F, VAVITT M B, SMITH. Deepwater gulf of Mexico development challenges [R]. SPE 113011, 2008. [2] DEKKER M, REID D. Deepwater development strategy[R]. OTC-25135, 2014. [3] SONG J J H, ROJAS J C. Preventing mud losses by wellbore strengthening [A]. SPE 101593, 2006. [4] 李怀科,罗健生,耿铁,等. 国内外深水钻井液技术进展[J]. 钻井液与完井液,2015,32(6):85-87.LI Huaike, LUO Jiansheng, GENG Tie, et al. Technical progress of deep water drilling fluids in China and abroad[J]. Drilling Fluid & Completion Fluid, 2015, 32(6):85-87. [5] 黄进军,罗平亚,李家学,等. 提高地层承压能力技术[J]. 钻井液与完井液,2009,26(2):69-71.HUANG Jinjun, LUO Pingya, LI Jiaxue, et al. A study on the enhancement of formation bearing resistance[J]. Drilling Fluid & Completion Fluid, 2009, 26(2):69-71. [6] 王贵,蒲晓林. 提高地层承压能力的钻井液堵漏作用机理[J]. 石油学报,2010,31(6):1009-1012.WANG Gui, PU Xiaolin. Plugging mechanism of drilling fluid by enhancing wellbore pressure[J]. Acta Petrolei Sinica, 2010, 31(6):1009-1012. [7] 黄达全,刘永存,穆剑雷,等. 承压堵漏技术在AT5井的应用[J]. 钻井液与完井液,2007,24(4):78-80.HUANG Daquan, LIU Yongcun, MU Jianlei, et al. Application of mud loss control under pressures technology in well AT5[J]. Drilling Fluid & Completion Fluid, 2007, 24(4):78-80. [8] 孙金声,苏义脑,罗平亚,等. 超低渗透钻井液提高地层承压能力机理研究[J]. 钻井液与完井液,2005,22(5):4-6.SUN Jinsheng, SU Yinao, LUO Pingya, et al. Mechanism study on ultra-low invasion drilling fluid for improvment of formation pressure-bearing ability[J]. Drilling Fluid & Completion Fluid, 2005, 22(5):4-6. [9] 万鑫,吴金桥,杨超,等. 延长油田页岩气水平井安全钻井液密度窗口探讨[J]. 非常规油气,2016,3(5):121-126.WAN Xin, WU Jinqiao, YANG Chao, et al. Study of safe drilling mud weight window for shale gas horizontal well in Yangchang oilfield[J]. Unconventonal Oil & Gas, 2016, 3(5):121-126. [10] 王禹,黄达全,解文,等. 板南储气库井承压封堵技术[J]. 钻井液与完井液,2013,30(3):47-49.WANG Yu, HUANG Daquan, XIE Wen, et al. Pressure-blocking technology for wells in Bannan gas storage[J]. Drilling Fluid & Completion Fluid, 2013, 30(3):47-49. [11] ASTON M S, ALBERTY M W, et al. Drilling fluids for wellbore strengthening [R]. SPE 87130, 2004. [12] 侯士立,黄达全,杨贺卫,等. 刚性楔入承压封堵技术[J]. 钻井液与完井液,2015,32(1):49-52.HOU Shili, HUANG Daquan, YANG Hewei, et al. Rigid wedge pressure-blocking technology[J]. Drilling Fluid & Completion Fluid, 2015, 32(1):49-52. [13] 张文哲,孙金声,白英睿,等. 抗高温纤维强化凝胶颗粒堵漏剂研究[J]. 钻井液与完井液,2020,37(3):269-274.ZHANG Wenzhe, SUN Jinsheng, BAI Yingrui, et al. Study on anti-high temperature fiber-reinforced gel particles[J]. Drilling Fluid & Completion Fluid, 2020, 37(3):269-274. -

下载:

下载: