A Viscosity Reducer for Oil Based Drilling Fluids and Its Field Application

-

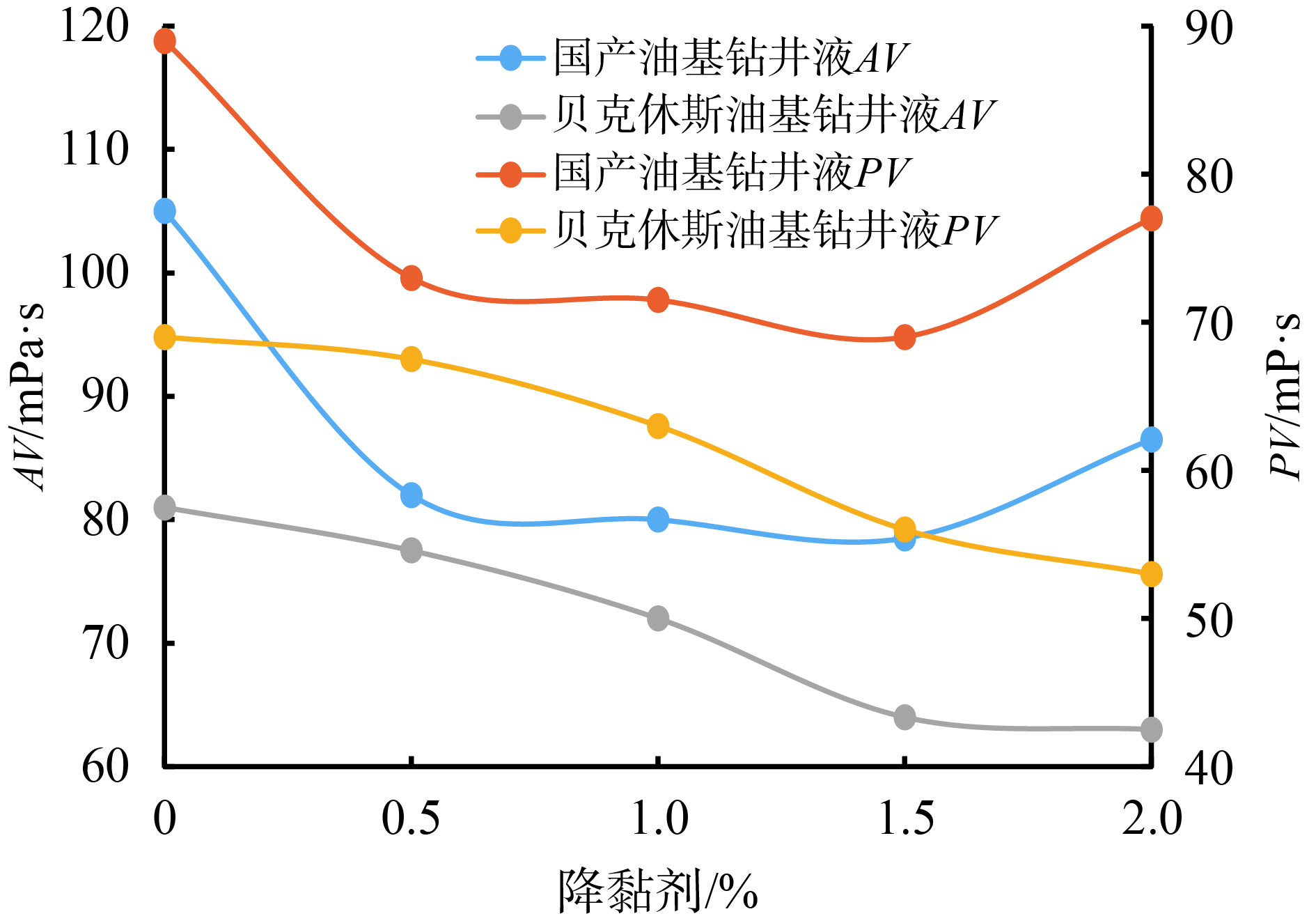

摘要: 高密度油基钻井液稠化的主要原因之一是钻井过程中劣质固相的侵入,特别是低密度固相含量的不断增加。劣质固相经过油基钻井液中的润湿剂、乳化剂作用后使其具有了一定的活性,增强体系的网架结构,导致钻井液的黏度和切力上涨。以月桂酰胺、硬脂酸酰胺和芥酸酰胺为原料,按照质量比1∶2∶1合成了分子链中具有可吸附胺基、酰胺基的多元活性基团的降黏剂CQ-OTA。降黏评价实验表明:CQ-OTA能够将固相含量为48.5%高密度稠化油基钻井液的塑性黏度降低25.0%,静切力降低60.0%,其在油基钻井液中的推荐加量为0.5%~1.5%;在威202HX平台现场应用,能够改善油基钻井液的流变性,提高劣质固相容量限,塑性黏度由53.0 mPa·s下降至40.0 mPa·s,10 min静切力由23 Pa下降至14.5 Pa,保证了高密度油基钻井液顺利钻至目的井深,提高了高密度油基钻井液重复使用效率,降低了钻井成本。Abstract: Invasion of low quality solids, especially the low density solids is one of the major factors causing the thickening of high density oil based drilling fluids. The low quality solids in an oil based drilling fluid, when in contact with the wetting agents and emulsifiers therein, attain a certain degree of activity, thereby strengthening the networking structure and increasing the viscosity and gel strengths of the drilling fluid. A viscosity reducer CQ-OTA with amino groups and amido groups in its molecules was developed with lauramide, octadecanamide and erucamide in a mass ratio of 1∶2∶1. Evaluation on the viscosity reduction capacity of CQ-OTA showed that it can reduce the plastic viscosity and gel strength by 25.0% and 60.0% respectively of a high density thickened oil based drilling fluid containing 48.5% solids. The recommended treatment of CQ-OTA in oil based drilling fluids is 0.5%-1.5%. CQ-OTA was used on the Wei-202HX platform and it effectively improved the rheology of the oil based drilling fluid. The threshold of the low quality solids in the drilling fluid was increased. The plastic viscosity of the oil based drilling fluid was reduced from 53.0 mPa·s to 40.0 mPa·s, the final (10 min) gel strength reduced from 23 Pa to 14.5 Pa, ensuring the successful drilling of the well with the oil based drilling fluid, and enhancing the efficiency of reusing the high density oil based drilling fluid. The drilling cost was thus greatly reduced.

-

Key words:

- High density oil-based drilling fluid /

- Viscosity reducer /

- Solid content /

- Rheology

-

表 1 劣质固相侵入对油基钻井液流变性的影响

岩屑粉/

%AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/Paφ6/φ3 0 46.5 38.0 8.5 2.5/6.0 6/5 5 47.0 39.0 8.0 2.5/6.0 6/5 10 52.5 43.0 9.5 3.0/7.5 7/6 15 58.5 47.5 11.0 3.5/8.5 7/6 20 69.5 57.0 12.5 4.0/11.5 9/7 表 2 CQ-OTA对新配浆油基钻井液性能的影响

CQ-OTA/

%AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/ Paφ6/φ3 ES/

VFLHTHP/

mL0 45.0 37.0 8.0 2.0/6.0 5/4 745 1.6 1.0 48.5 39.0 9.5 2.5/7.0 7/5 816 1.2 注:FLHTHP在120 ℃测定 表 3 威202HX-3井油基钻井液的性能随井深的变化

井深 AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/Pa3000 43.5 36 7.5 3.5/12.5 3587 45.0 37 8.0 4.0/14.0 4385 51.5 43 8.5 5.0/16.0 4742 49.5 39 10.5 5.0/18.0 5146 67.0 53 14.0 7.5/23.0 表 4 威202HX-3井油基钻井液性能

井深/

mFV/

sρ/

g·cm−3AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/ PaES/

VFLHTHP/

mLVs/

%2906 61 1.98 43.5 36.0 7.5 3.5/12.5 843 1.2 39.5 3587 64 2.02 45.0 37.0 8.0 4.0/14.0 915 1.4 41.0 4385 66 2.02 51.5 43.0 8.5 5.0/16.0 874 1.4 43.0 4742 68 2.05 49.5 39.0 10.5 5.0/18.0 955 2.0 45.0 5146 73 2.03 67.0 53.0 14.0 7.5/23.0 968 2.2 46.0 5217 64 2.02 50.5 40.0 9.5 4.5/14.5 1024 1.6 46.5 注:FLHTHP在120 ℃测定 -

[1] 鄢捷年. 钻井液工艺学[M]. 山东: 石油大学出社, 2001.YAN Jienian. Drilling fluid technology[M]. Shandong: Petroleum University Press, 2001 [2] 王中华. 国内外油基钻井液研究与应用进展[J]. 断块油气田,2011,18(4):553-537.WANG Zhonghua. Research and application progess of oil-based drilling fluid at home and abroad[J]. Fault-Block Oil & Gas Field, 2011, 18(4):553-537. [3] 徐安, 岳前升. 油基钻井液及其处理剂研究进展综述[J]. 长江大学学报自然科学版:石油/农学(中旬),2013,10(8):77-79.XU An, YUE Qiansheng. Review on research progress of oil based drilling fluid and its treatment agent[J]. Journal of Yangtze University(Nat Sci Edit) , 2013, 10(8):77-79. [4] 朱金智,徐同台, 吴晓花,等. 加重剂对抗高温超高密度柴油基钻井液性能的影响[J]. 钻井液与完井液,2019,36(2):160-164. doi: 10.3969/j.issn.1001-5620.2019.02.005ZHU Jinzhi, XU Tongtai, WU Xiaohua, et al. The effects of weight materials on the performance of high temperature ultrahigh-density diesel oil base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(2):160-164. doi: 10.3969/j.issn.1001-5620.2019.02.005 [5] 卢俊安,王春生,冯少波,等. 超高压盐水溢流处置技术[J]. 钻采工艺,2017,40(5):5-7. doi: 10.3969/J.ISSN.1006-768X.2017.05.02LU Jun’an, WANG Chunsheng, FENG Shaobo, et al. Disposal measures for ultra-hing-press brine overflow[J]. Drilling & Production Technology, 2017, 40(5):5-7. doi: 10.3969/J.ISSN.1006-768X.2017.05.02 [6] 王昌军,艾俊哲,王正良,等. 涠洲油田油基钻井液黏稠物的形成机理[J]. 钻井液与完井液,2010,27(5):25-27. doi: 10.3969/j.issn.1001-5620.2010.05.008WANG Changjun, AI Junzhe, WANG Zhengliang, et al. Mechanism of oil based drilling fluid brei forming in Weizhou oilfield[J]. Drilling Fluid & Completion Fluid, 2010, 27(5):25-27. doi: 10.3969/j.issn.1001-5620.2010.05.008 [7] 陶怀志,吴正良,贺海. 国产油基钻井液CQ-WOM首次在页岩气威远H3-1井试验[J]. 钻采工艺,2014,37(5):87-90. doi: 10.3969/J.ISSN.1006-768X.2014.05.28TAO Huaizhi, WU Zhengliang, HE Hai. Test of oil-base drilling fluid CQ-WOM made in china in weiyuan H3-1 shale gas well[J]. Drilling & Production Technology, 2014, 37(5):87-90. doi: 10.3969/J.ISSN.1006-768X.2014.05.28 [8] 杨振周,刘付臣, 周春, 等. 抗超高温高密度油基钻井液用新型降黏剂的性能[J]. 钻井液与完井液,2018,35(2):35-39. doi: 10.3969/j.issn.1001-5620.2018.02.005YANG Zhenzhou, LIU Fuchen, ZHOU Chun, et al. Study on the performance of new ultra-high temperature high density oil base mud thinners[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):35-39. doi: 10.3969/j.issn.1001-5620.2018.02.005 [9] 米远祝, 罗跃,黄志强. 油基钻井液增黏剂的合成及室内评价[J]. 钻井液与完井液,2014,31(1):4-7. doi: 10.3969/j.issn.1001-5620.2014.01.002MI Yuanzhu, LUO Yue, HUANG Zhiqiang. Synthesis and laboratory evaluation of viscosifier for oil-based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2014, 31(1):4-7. doi: 10.3969/j.issn.1001-5620.2014.01.002 [10] 胡润涛. 油基钻井液油相组成分析与有机改性材料在油基钻井液中的作用机理分析[D]. 山东: 山东大学, 2019.HU Runtao. Analysis of oil phase composition of oil-base drilling fluid and mechanism of action of organic modified materials in oil-base drilling fluid[D]. Shandong: Shandong University, 2019. [11] 代一钦, 梁文利. 油基钻井液降黏剂研制及现场应用[J]. 江汉石油职工大学学报,2019,32(6):39-42.DAI Yiqin, LIANG Wenli. Development and field application of oil-base drilling fluid viscosity reducing[J]. Jianghan Petroleum University of Staff and Workers, 2019, 32(6):39-42. [12] 张高波,高秦陇,马倩芸. 提高油基钻井液在页岩气地层抑制防塌性能的措施[J]. 钻井液与完井液,2019,36(2):141-147. doi: 10.3969/j.issn.1001-5620.2019.02.002ZHANG Gaobo, GAO Qinlong, MA Qianyun. Discussion on the enhancement of the inhibitive capacity of oil base drilling fluids in shale gas drilling[J]. Drilling Fluid & Completion Fluid, 2019, 36(2):141-147. doi: 10.3969/j.issn.1001-5620.2019.02.002 -

下载:

下载: