An Environmentally Friendly High Temperature Water Based Drilling Fluid for Hot-Dry-Rock Well Drilling

-

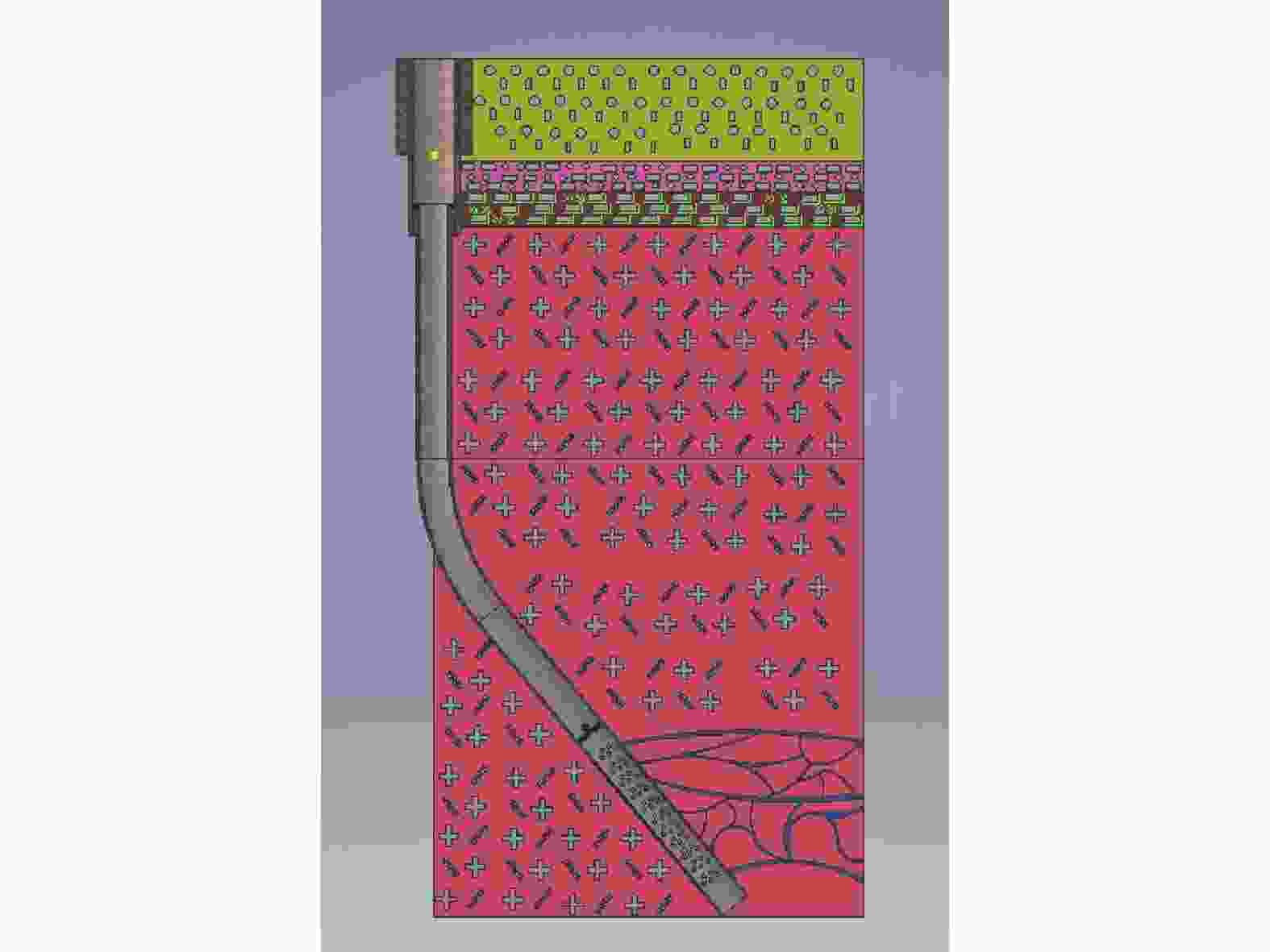

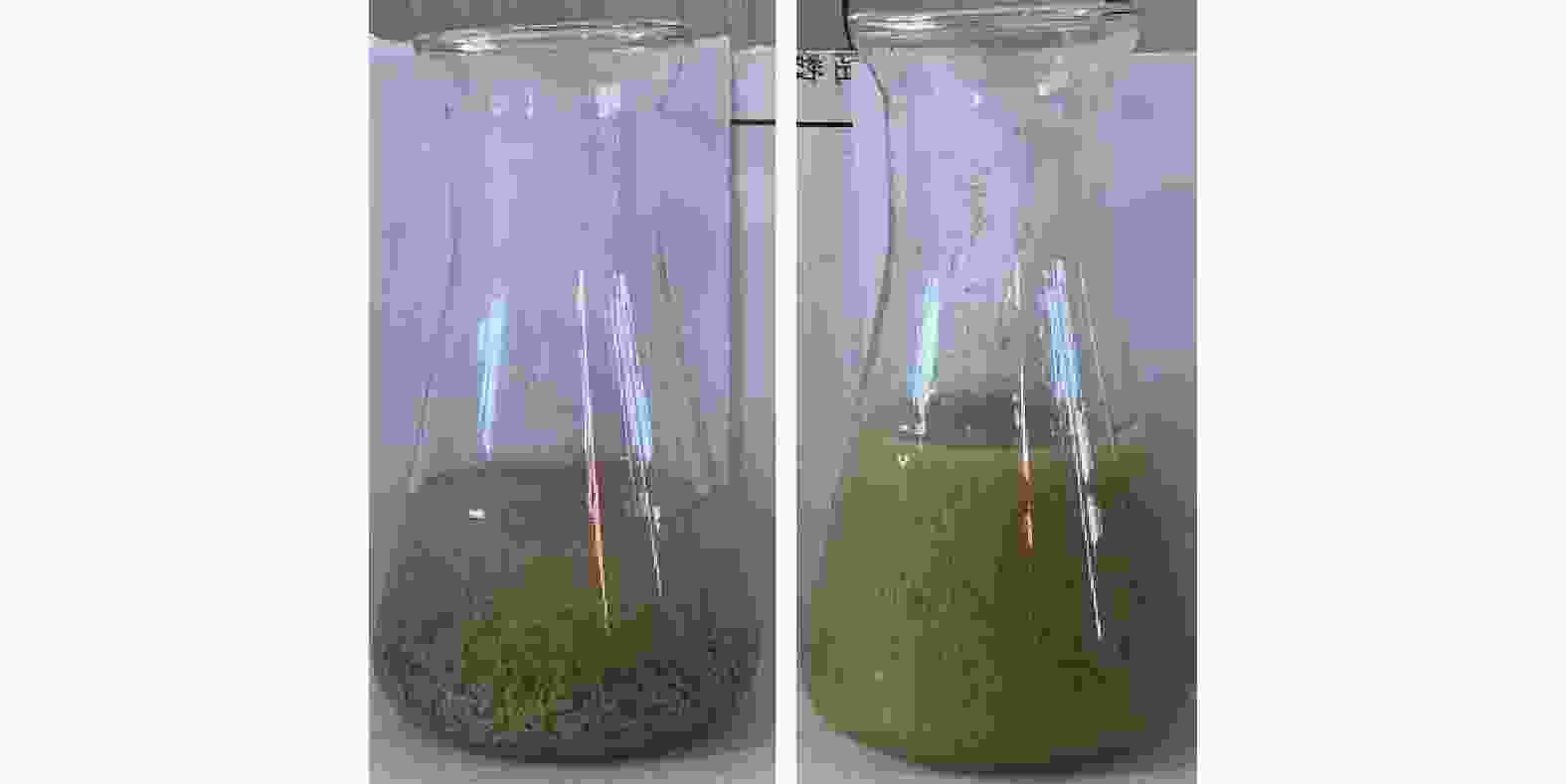

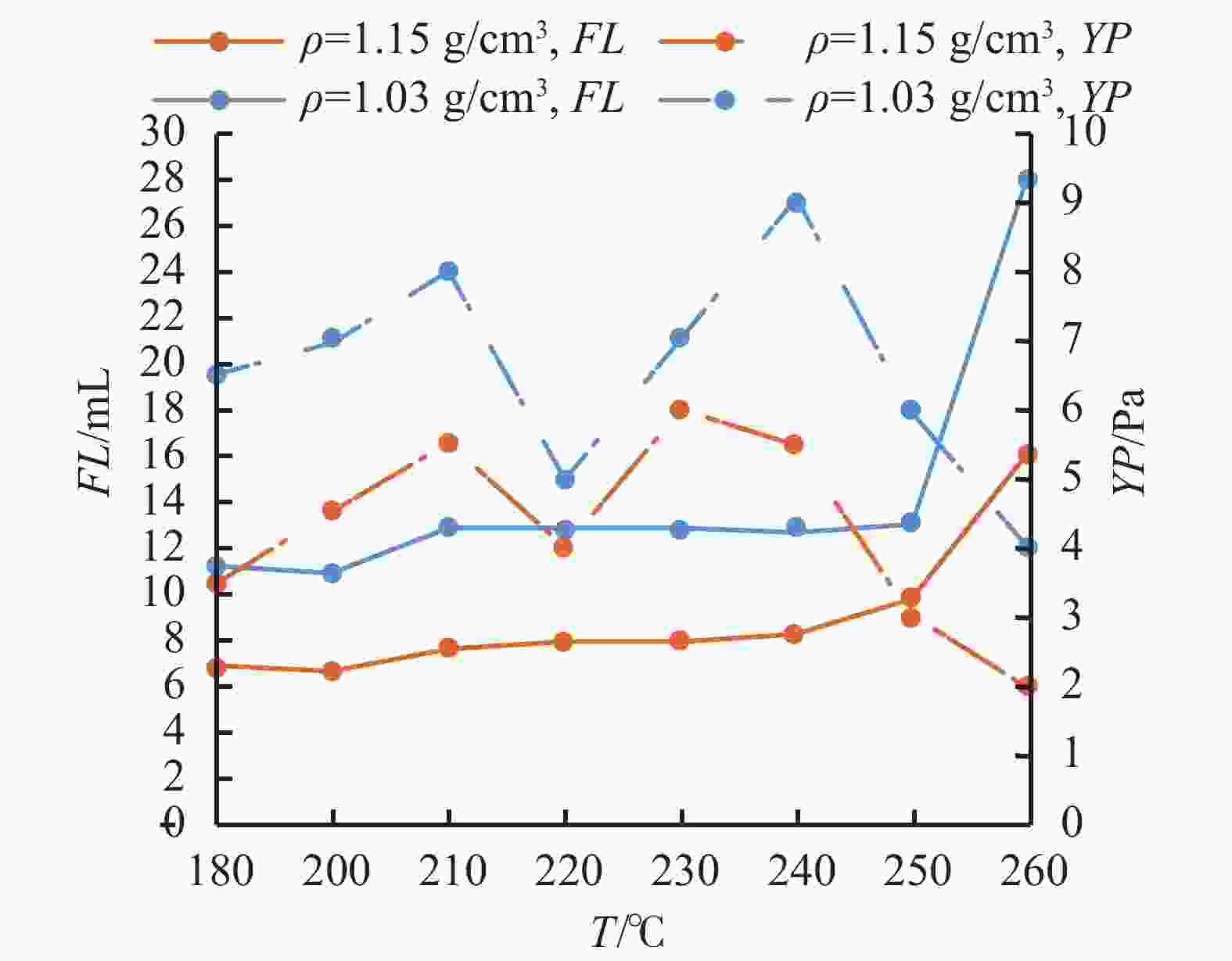

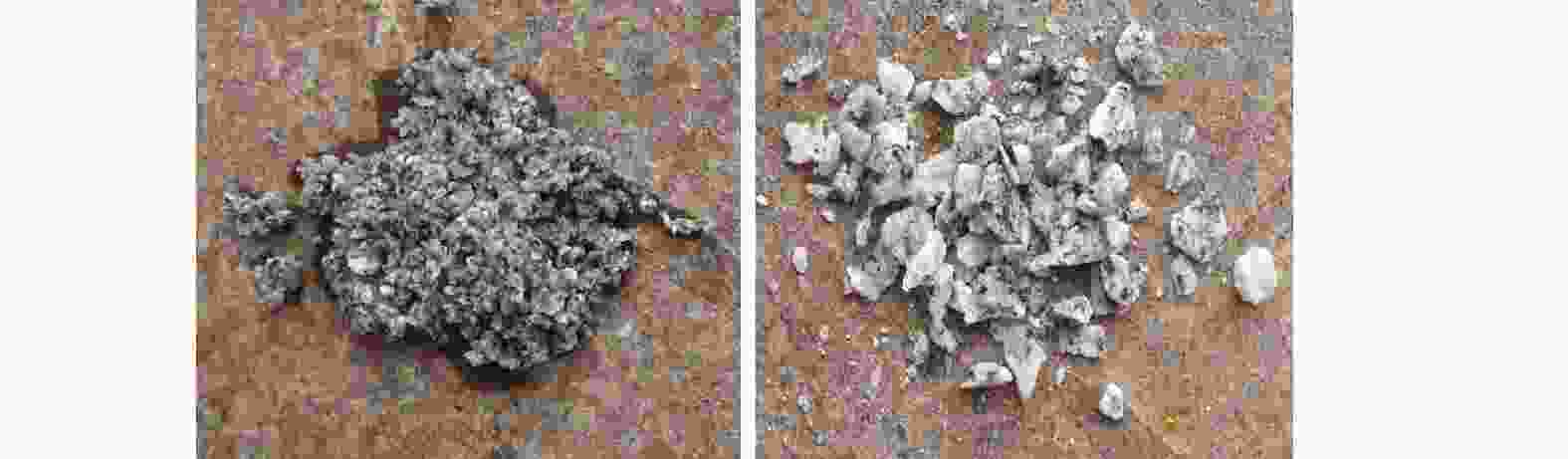

摘要: 传统能源储量日益减少,干热岩类新型能源的开发变得尤为重要。然而干热岩井底温度较高、井深较深且存在造斜井段、其周边有自然保护区,对钻井液的高温稳定性、环保性有着严格的要求。如果能设计高效的抗高温钻井液体系,将会对干热岩的开发起到事半功倍的效果。因此对30余种处理剂进行常规性能测试与热滚老化实验,通过控制变量、正交实验等方法,根据干热岩特征对钻井液的组分、含量进行设计筛选,得到一套干热岩抗高温钻井液体系,并对该体系在不同温度、密度、老化时长的条件下进行抗温性能测试。实验结果表明,该钻井液体系在240 ℃高温下依然有较好的高温稳定性;该体系采用聚合物类处理剂,其内部形成的网架结构稳定,不易被高温破坏,同时针对地层特点而设计的泥饼薄且有韧性、对井壁侵蚀性较小;除此之外还采用了白色无污染原材料,不含磺化、油基成分,性能环保,对周边环境污染性小。Abstract: As the traditional energy reserves are declining, the development of new energy, such as hot-dry-rock, is becoming more and more popular. Hot-dry-rock wells have high bottom hole temperatures and are very deep, and sometimes are drilled directionally. Furthermore, some hot-dry-rock wells are located in an area surrounded by nature reserves. These factors impose strict requirements on the high temperature stability and environmental friendliness of the drilling fluid used to the hot-dry-rock well. If an efficient high-temperature drilling fluid can be formulated, it will do more with less in developing hot-dry-rock energy. In laboratory experiment, regular performance test and hot-rolling aging test were performed on more than 30 additives. The component and concentration of a drilling fluid for hot-dry-rock well drilling were designed and screened through variable control and orthogonal test methods. As a result, a high temperature drilling fluid for hot-dry-rock well drilling was developed. Laboratory experiment shows that this drilling fluid has good stability at temperatures as high as 240 °C. Polymers used in this drilling fluid form a stable network structure which is not easy to be destroyed by high temperature. The mud cakes formed by the drilling fluid is thin and tough, and is able to protect the borehole wall from being eroded. Some white non-polluting materials free of sulfonated and oil-based ingredients were also used in formulating the drilling fluid, they are environmentally friendly and pose very little pollution to the environment.

-

表 1 20种降滤失剂在200 ℃热滚16 h前后的性能变化

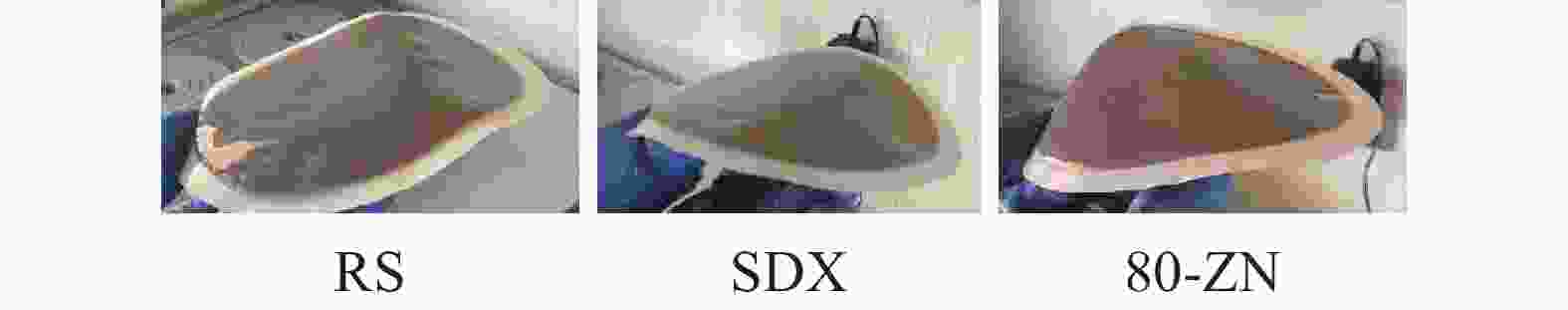

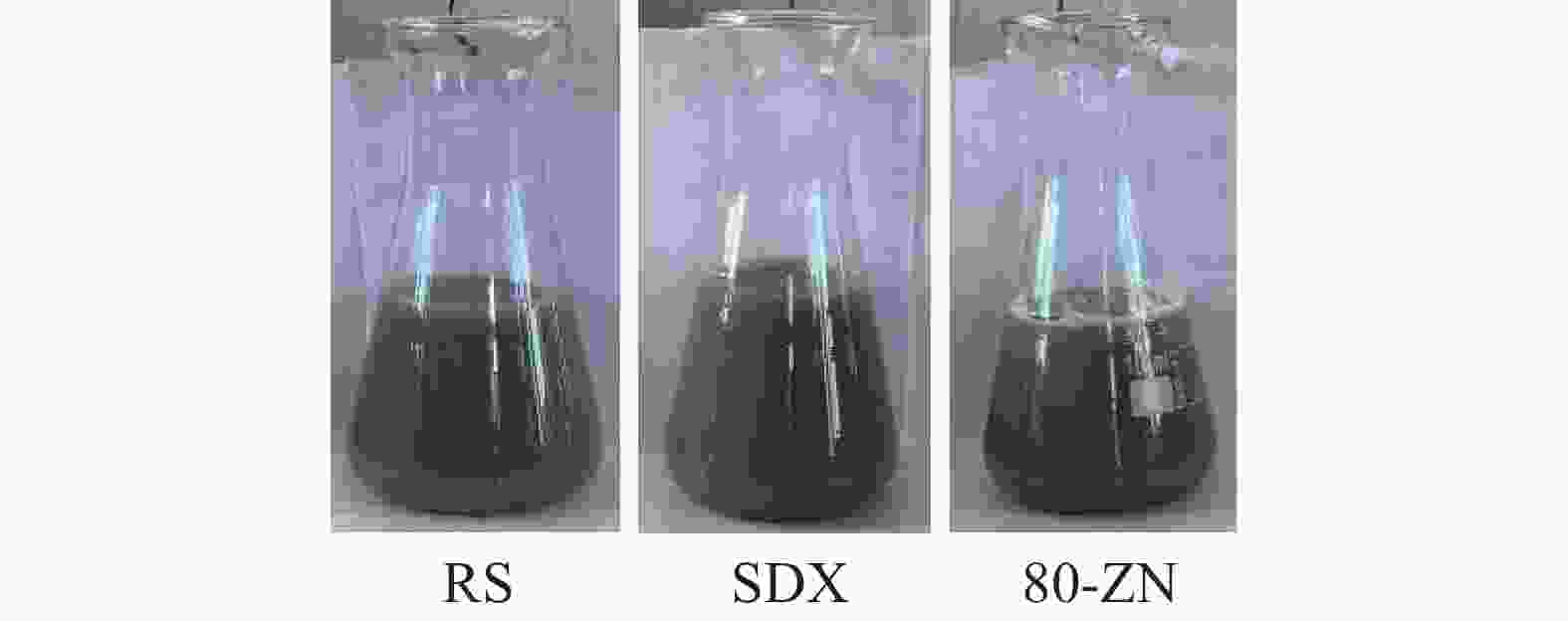

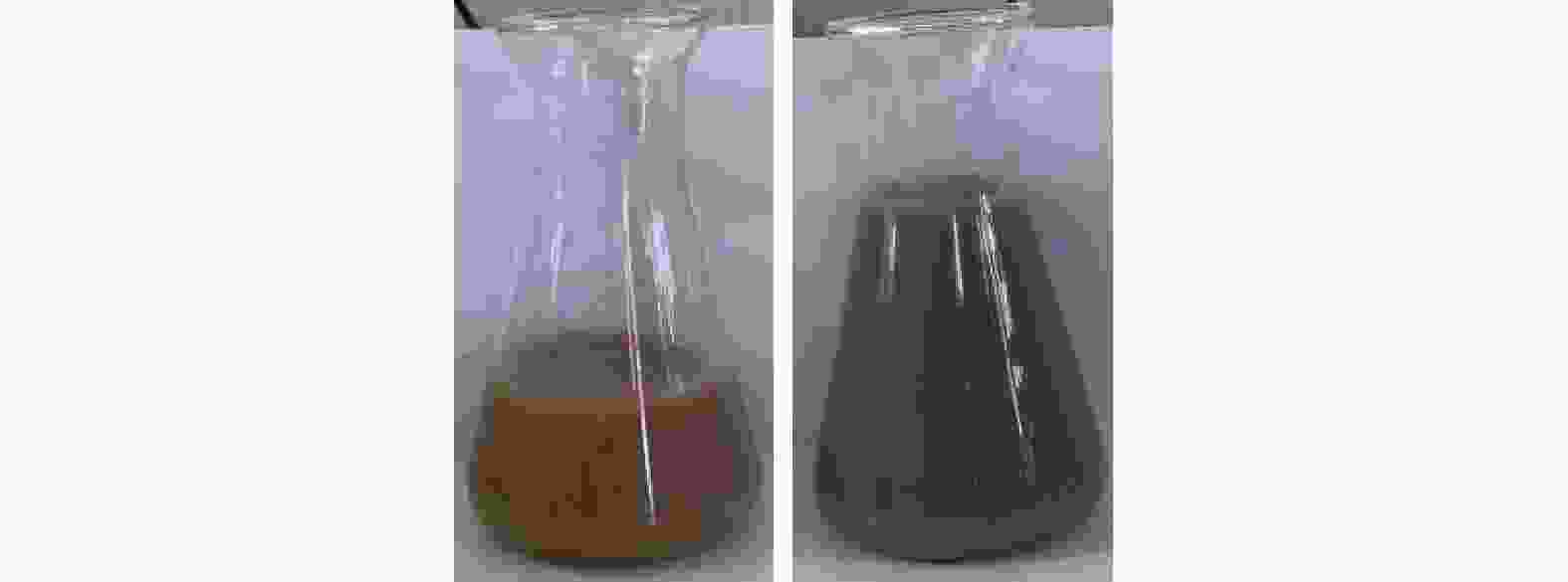

名称 实验条件 PV/mPa·s YP/Pa Gel/(Pa/ Pa) FL/mL pH 热滚后状态 M1H 热滚前 13.0 5.5 0.7/2.0 5.0 12 有刺激性气味,泡沫多 热滚后 52.0 46.0 5.0/5.5 >50.0 7 TH 热滚前 2.5 0 0/0 9.6 12 泥饼黏稠,浆液稀 热滚后 4.0 2.5 0/0 >30.0 10 SDX 热滚前 9.0 3.0 0.5/1.0 6.6 12 黏度低,泥饼较好、光滑有韧性 热滚后 9.0 1.5 0/0 16.4 9 JHDF 热滚前 14.0 8.0 0.2/2.0 5.4 12 有刺激性气味,泡沫多 热滚后 3.0 5.0 1.5/2.0 >70.0 5 80-ZN 热滚前 10.0 5.0 1.0/1.5 9.5 12 泥饼质量较好,浆液黏度太低 热滚后 8.0 1.0 0/0 14.8 9 NY-1 热滚前 22.0 4.5 0/0.2 7.0 12 泡沫多,泥饼粗糙、厚 热滚后 3.0 1.0 0/0.2 >50.0 8 聚丙JL-2 热滚前 9.0 6.0 0.5/1.5 21.0 12 泡沫较多,泥饼稀松不紧密 热滚后 26.0 20.0 2.0/4.5 >70.0 10 三元滤失A 热滚前 10.0 3.0 0/0.5 6.4 12 泡沫多,泥饼光滑紧密,较厚 热滚后 3.0 0.5 0/0.5 >60.0 8 三元滤失B 热滚前 3.0 0 0/0.5 9.6 12 泡沫很多,泥饼粗糙 热滚后 21.0 7.0 1.0/7.0 40.0 9 二元滤失A 热滚前 3.0 0.5 0/0 9.4 12 泡沫多,泥饼光滑紧密 热滚后 19.0 8.5 1.5/8.0 42.0 9 二元滤失B 热滚前 3.0 0 0/0.5 9.6 12 泡沫多,泥饼粗糙 热滚后 21.0 7.0 1.0/7.0 40.0 9 RJ-1 热滚前 31.0 21.0 2.0/6.0 20.0 12 泡沫多,泥饼光滑、薄、韧性低 热滚后 3.0 −0.5 0/0 >60.0 7 RJ-2 热滚前 11.0 2.5 0/1.0 20.0 12 泡沫多 热滚后 19.0 11.5 2.0/4.5 >60.0 7 RS 热滚前 14.0 4.5 1.5/2.5 8.0 12 泥饼质量较好 热滚后 14.0 8.0 1.25/2.5 14.0 10 聚丙HY 热滚前 4.0 1.0 0/0 20.0 12 泡沫较多,泥饼质量好 热滚后 2.0 0 0/0 28.0 9 磺化沥青粉 热滚前 2.0 1.0 0/0.2 27.0 12 热滚后 3.0 −0.5 0/0.5 >60.0 8 磺化酚醛树脂 热滚前 2.0 1.0 0/0.2 16.8 12 5 min滤失量>100 热滚后 19.0 11.5 2.0/5.0 >100.0 7 褐煤树脂 热滚前 18.0 7.0 0.5/5.5 24.0 12 泡沫多 热滚后 9.0 1.5 0/1.2 >70.0 9 腐植酸钾 热滚前 4.0 0.5 0/0.5 17.0 12 泡沫多 热滚后 14.0 8.0 1.0/5.5 >60.0 9 CZ-JL 热滚前 14.0 4.0 0.5/2.5 8.8 12 热滚后 1.0 0 0/0 >100.0 8 表 2 10种增黏剂在200 ℃热滚16 h前后的性能

增黏剂 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/ Pa80A-51 热滚前 20.0 15 5.0 1.2/2.5 热滚后 5.0 5 1.0 0/0.2 ZDJ-3 热滚前 6.0 3 3.0 1.0/1.5 热滚后 1.0 1 0 0/0 BBJ-4 热滚前 16.5 12 4.5 0.7/1.0 热滚后 13.0 9 4.0 0.5/1.5 CMC-HV-H1 热滚前 62.5 32 30.5 3.6/11.0 热滚后 2.0 1 1.0 0/0.2 SJ-LV 热滚前 12.0 11 1.0 0/0.5 热滚后 3.0 2 1.0 0/0 SJ-20 热滚前 52.0 25 27.0 4.5/6.5 热滚后 3.0 3 0.5 0/0 PAC-HV-2 热滚前 15.5 14 1.5 0/0 热滚后 2.5 1 1.5 0/0.5 PAC-HV-3 热滚前 10.0 9 1.0 0/0 热滚后 1.5 2 −0.5 0/0 黄原胶 热滚前 22.5 10 12.5 5.5/7.5 热滚后 1.0 1 0 0/0 SL-2 热滚前 8.0 6 2.0 0/0.5 热滚后 6.0 5 1.0 0/0 表 3 正交实验配方

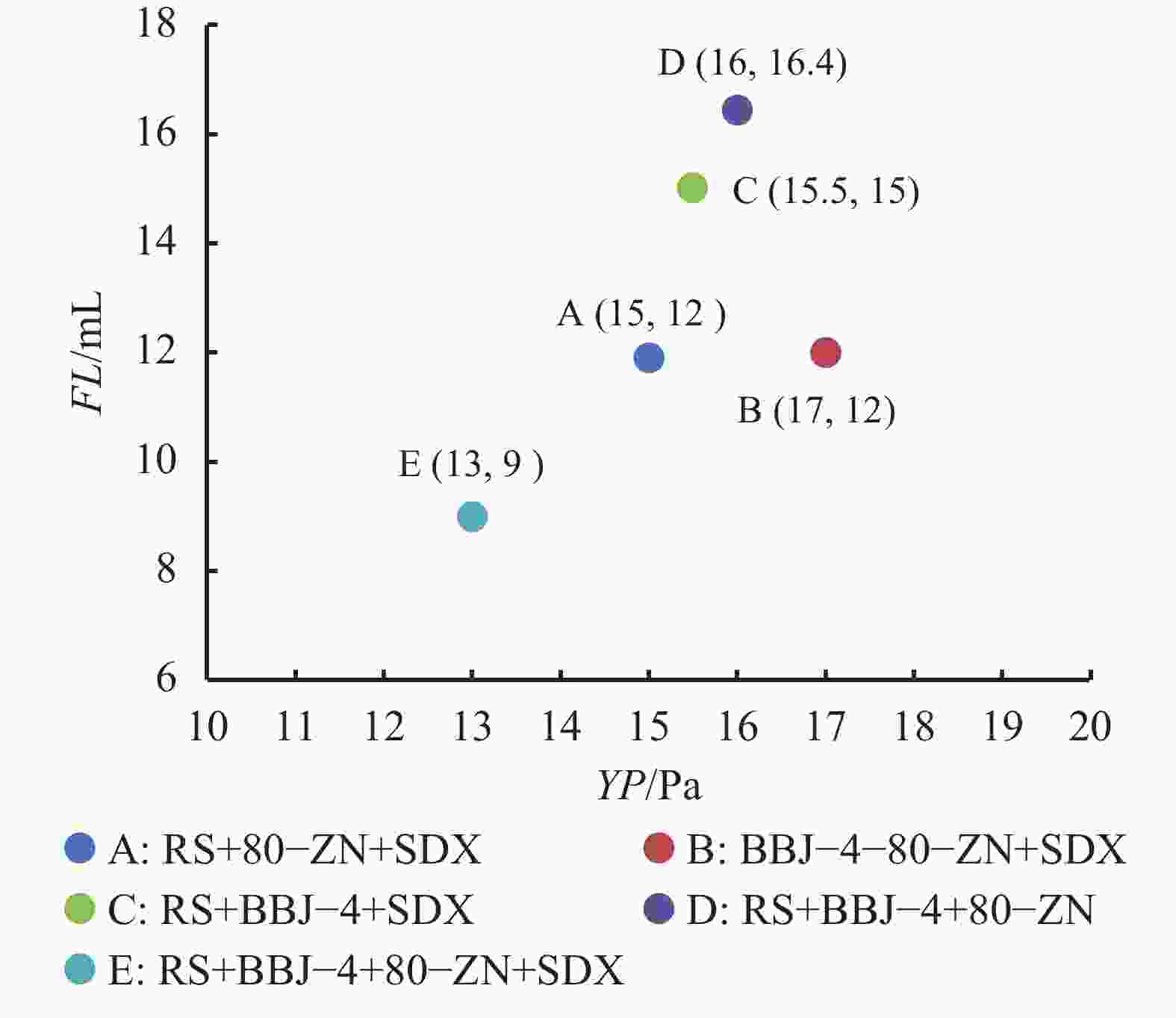

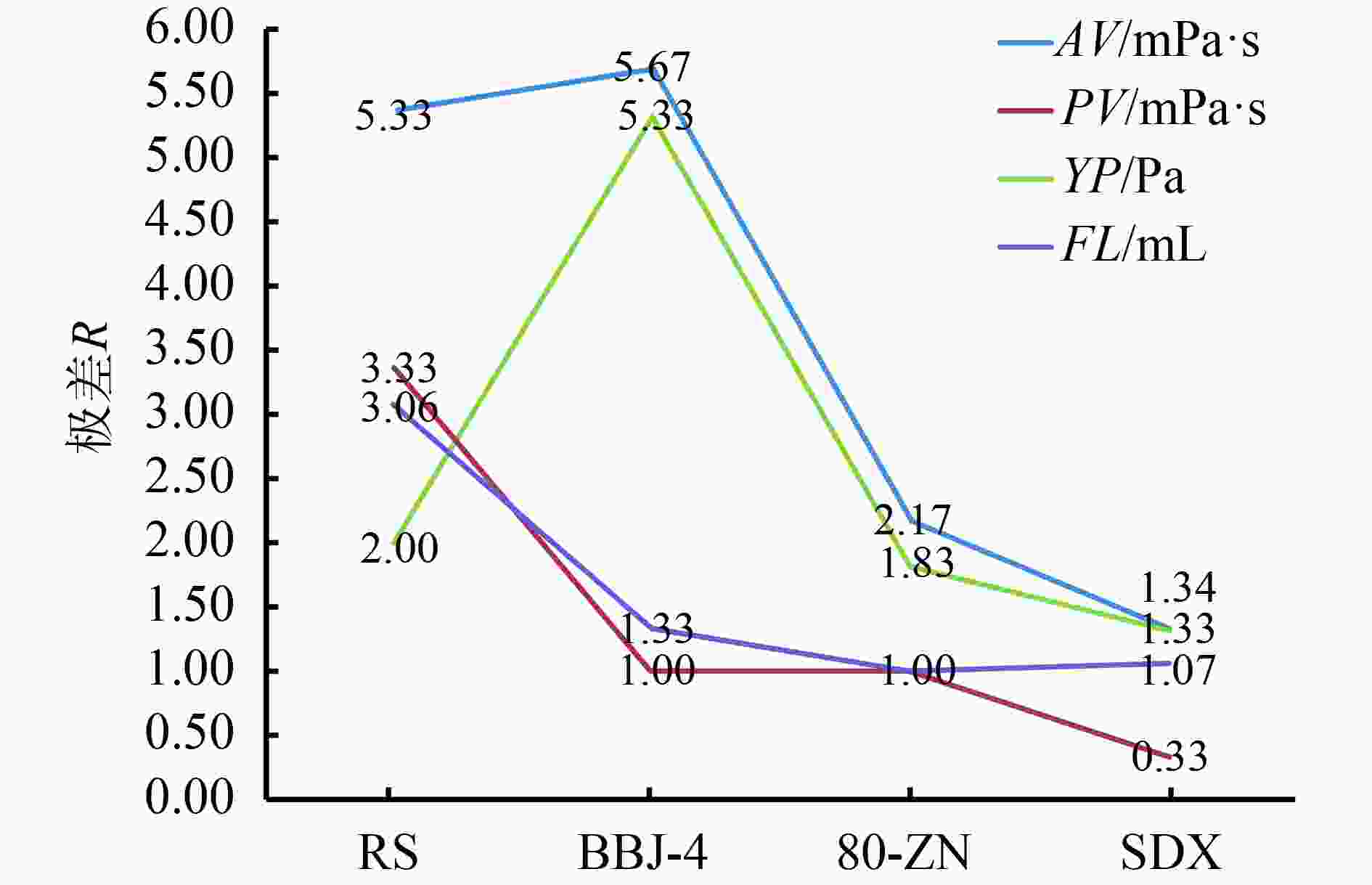

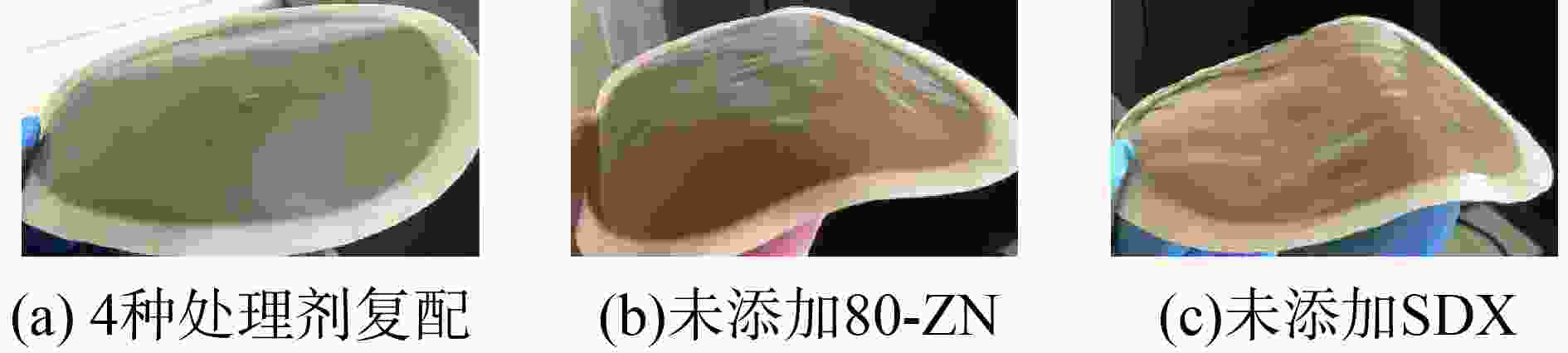

配方 RS/% BBJ-4/% 80-ZN/% SDX/% 1# 0.4 0.3 0.2 0.4 2# 0.4 0.5 0.5 0.5 3# 0.4 1.0 0.7 0.6 4# 0.6 0.3 0.5 0.6 5# 0.6 0.5 0.7 0.4 6# 0.6 1.0 0.2 0.5 7# 0.8 0.3 0.7 0.5 8# 0.8 0.5 0.2 0.6 9# 0.8 1.0 0.5 0.4 表 4 正交实验配方结果(200 ℃热滚16 h后的性能)

配方 pH AV/

mPa·sPV/

mPa·sYP/

PaFL/

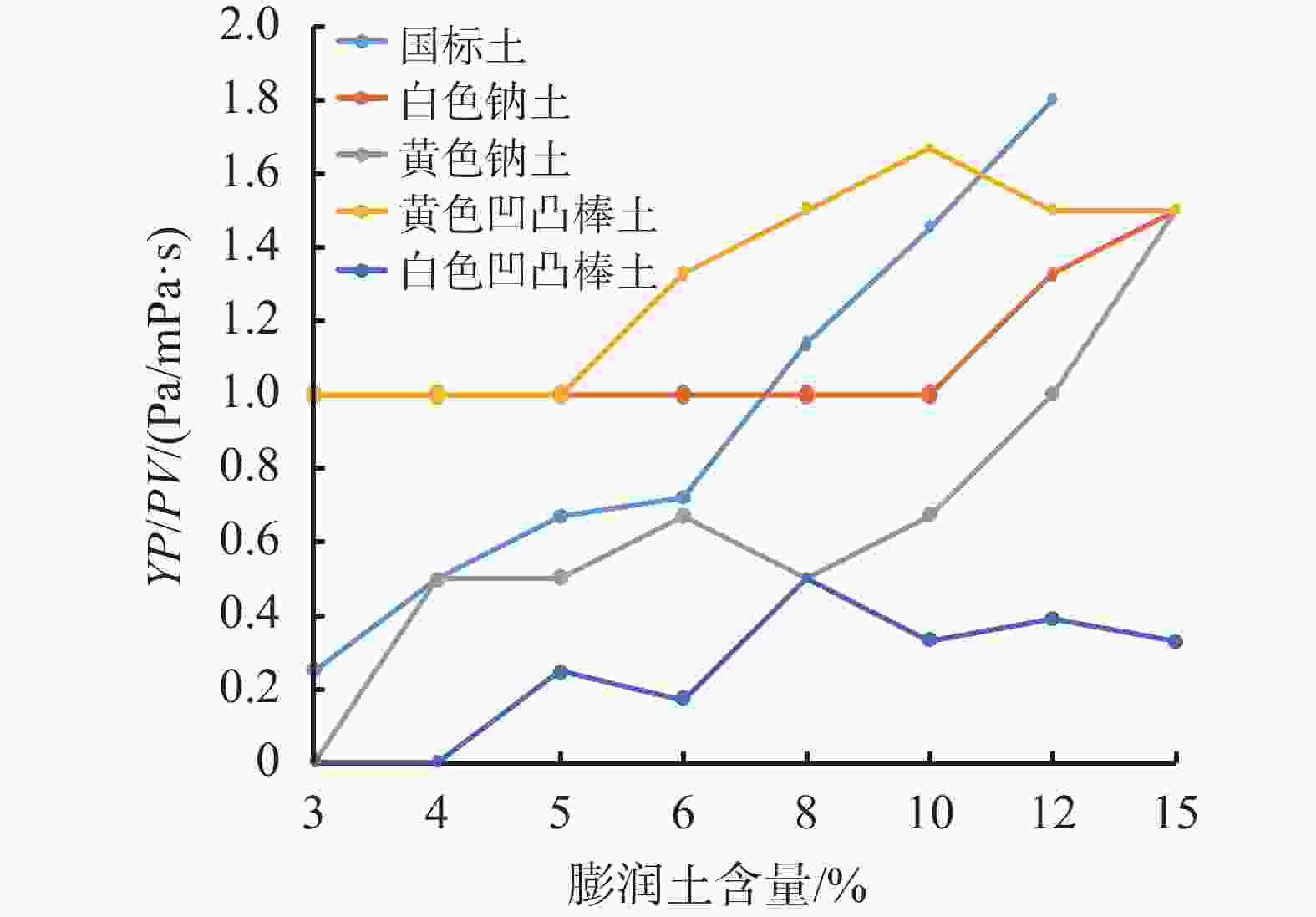

mL1# 10 25.0 15 10.0 14.2 2# 10 28.0 14 14.0 13.2 3# 9 32.5 16 16.5 10.8 4# 9 26.5 15 11.5 10.8 5# 9 30.0 15 15.0 10.8 6# 9 33.0 16 17.0 9.6 7# 10 33.5 19 14.5 9.2 8# 10 31.5 18 13.5 10.0 9# 9 36.5 18 18.5 9.8 表 5 膨润土比例优选(总土含量为3%)

白色钠土∶国标钠土 AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFL/

mL3∶1 24.5 18 6.5 0.5/0.5 12.8 2∶1 29.5 19 10.5 1.2/1.5 12.8 1∶1 3.0 20 11.0 1.0/1.2 12.4 1∶2 30.0 19 11.0 1.0/1.5 11.8 1∶3 26.0 17 9.0 0.7/1.0 12.2 表 6 膨润土含量优选(在200 ℃热滚16 h)

膨润土/

%AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFL/

mL2 18.0 15.0 3.0 0/0 18.4 3 24.5 18.0 6.5 0.5/0.5 12.8 4 47.0 31.0 16.0 2.0/2.0 8.4 5 57.5 35.0 22.5 2.0/2.0 8.0 6 79.0 52.0 27.0 2.0/2.0 7.0 表 7 不同密度钻井液在240 ℃热滚不同时间后的性能

ρ/

g·cm−3t热滚/

hAV/

mPa·sPV/

mPa·sYP/

PaFL/

mLFLHTHP/

mL1.03 0 37.5 30 7.5 14.0 16 26.5 16 10.5 10.6 24 26.0 15 11.0 10.6 48 24.5 16 8.5 10.8 72 24.5 19 5.5 11.0 1.15 0 37.5 27 10.5 13.5 16 28.0 16 12.0 10.0 24 27.0 14 13.0 10.0 48 25.0 12 13.0 10.2 72 25.0 13 12.0 10.2 1.30 0 52.5 21 31.5 13.0 16 25.0 20 5.0 9.8 24 25.5 19 6.5 9.8 48 24.0 18 6.0 9.8 72 23.5 17 6.5 10.0 1.40 0 66.0 38 28.0 13.0 16 48.0 23 25.0 6.0 24 28.0 18 10.0 6.8 48 26.5 18 8.5 7.0 72 26.0 17 9.0 7.4 1.50 0 66.5 43 23.5 13.2 16 50.0 24 26.0 6.2 24 90.0 40 50.0 18.0 48 46.0 20 26.0 6.2 72 40.0 21 19.0 6.5 注:FLHTHP使用FANN38771型高温滤失仪,在160 ℃、30 min下测定 表 8 干热岩抗高温环保水基钻井液的抗钻屑污染性能

ρ/

g·cm−3钻屑/

%AV/

mPa·sPV/

mPa·sYP/

PaFL/

mLFLHTHP/

mL1.03 5 33.0 25 8.0 5.2 10.6 1.03 10 27.5 19 8.5 5.4 11.0 1.03 15 23.5 17 6.5 5.6 11.5 1.40 5 48.5 25 23.5 4.6 9.8 1.40 10 45.0 23 22.0 4.8 10.0 1.40 15 43.5 27 16.5 5.0 9.6 注:FLHTHP在160 ℃、30 min下测定 表 9 干热岩抗高温环保水基钻井液热滚前后的润滑性能

ρ/

g·cm−3摩阻系数 热滚前 热滚后 1.03 2.023 2.044 1.15 2.027 2.058 1.30 2.030 2.062 1.40 2.035 2.066 -

[1] 付亚荣,李明磊,王树义,等. 干热岩勘探开发现状及前景[J]. 石油钻采工艺,2018,40(4):526-540.FU Yarong, LI Minglei, WANG Shuyi, et al. Present situation and prospect of hot dry rock exploration and development[J]. Oil Drilling & Production Technology, 2018, 40(4):526-540. [2] 卜海,徐同台,孙金声,等. 高温对钻井液中黏土的作用及作用机理[J]. 钻井液与完井液,2010,27(2):23-25,88. doi: 10.3969/j.issn.1001-5620.2010.02.007BU Hai, XU Tongtai, SUN Jinsheng, et al. The effect of high temperature on clays in drilling fluids[J]. Drilling Fluid & Completion Fluid, 2010, 27(2):23-25,88. doi: 10.3969/j.issn.1001-5620.2010.02.007 [3] 单文军,陶士先,蒋睿,等. 干热岩用耐高温钻井液关键技术及进展[J]. 探矿工程(岩土钻掘工程),2018,45(10):52-56.SHAN Wenjun, TAO Shixian, JIANG Rui, et al. Key technology and progress in hightemperature resistant drilling fluid for dry rock[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling) , 2018, 45(10):52-56. [4] 孙金声,黄贤斌,吕开河,等. 提高水基钻井液高温稳定性的方法、技术现状与研究进展[J]. 中国石油大学学报(自然科学版),2019,43(5):73-81.SUN Jinsheng, HUANG Xianbin, LYU Kaihe, et al. Methods, technical progress and research advance of improving high-temperature stability of water based drilling fluids[J]. Journal of China University of Petroleum (Edition of Natural Science) , 2019, 43(5):73-81. [5] 卢俊锋. 废弃聚磺钻井液固液相分离及处理研究[D]. 成都: 西南石油大学, 2018.LU Junfeng.Study on solid liquid separation and treatment of waste polysulfonate drilling fluid[D]. Chengdu: Southwest Petroleum University, 2018. [6] GALINDO K A, DEVILLE J P, ESPAGNE B J L, et al. Fluorous-based drilling fluid for ultra-high temperature wells[C]. Society of Petroleum Engineers. SPE-166126-MS. [7] AUNG T H. High temperature drilling fluids in the cooper-eromanga basin, australia[C]. Society of Petroleum Engineers. doi: 10.2118/14616-MS [8] YUZHI X, GONGRANG L , BAOFENG L, et al. Application of super high density drilling fluid under ultra-high temperature on well Shengke-1[C]. Society of Petroleum Engineers. doi: 10.2118/131189-MS [9] WENLONG Z, XIAOMING W, YUMING H , et al. Research and application of high-temperature drilling fluid for scientific core drilling project[C]. Society of Petroleum Engineers. doi: 10.2118/188906-MS [10] 郑宇轩,单文军,赵长亮,等. 青海共和干热岩GR1井钻井工艺技术[J]. 地质与勘探,2018,54(5):1038-1045.ZHENG Yuxuan, SHAN Wenjun, ZHAO Changliang, et al. Qinghai republican hot dry rock GR1 well drilling technology[J]. Geology and Exploration, 2018, 54(5):1038-1045. [11] GALINDO K A, ZHA W, ZHOU H, et al. High temperature, high performance water-based drilling fluid for extreme high temperature wells[C]. Society of Petroleum Engineers. doi: 10.2118/173773-MS [12] LIU X, GAO Y , HOU W , et al. Non-toxic high temperature polymer drilling fluid significantly improving marine environmental acceptabiiity and reducing cost for offshore drilling[J].International Petroleum Technology Conference. doi: 10.2523/IPTC-19425-MS [13] AL-HAMEEDI A T T, ALKINANI H H, DUNN-NORMAN S, et al. Proposing a new eco-friendly drilling fluid additive to enhance the filtration properties of water-based drilling fluid systems[C]. Society of Petroleum Engineers. doi: 10.2118/198651-MS [14] 张永青,胡景东,许朋琛,等. HL-FFQH环保型水基钻井液体系的构建及应用[J]. 钻井液与完井液,2019,36(4):437-441,448. doi: 10.3969/j.issn.1001-5620.2019.04.007ZHANG Yongqing, HU JingDong, XU Pengchen, et al. Development and application of the environmentally friendly HL-FFQH water base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):437-441,448. doi: 10.3969/j.issn.1001-5620.2019.04.007 [15] ZHOU J, NASR-EL-DIN H A. A new application of potassium nitrate as an environmentally friendly clay stabilizer in water-based drilling fluids[C]. Society of Petroleum Engineers. doi: 10.2118/184578-MS [16] FRIEDHEIM J E. Second-generation synthetic drilling fluids[C]. Society of Petroleum Engineers. doi: 10.2118/38251-JPT [17] ZHU J, YANG Z , LI X , et al. Synergistic effect between wormlike micelles and nanoparticles in stabilizing foams for high temperature stimulation[C]. Society of Petroleum Engineers. doi: 10.2118/191711-18RPTC-MS [18] PINO R , ABOUHAMED A , ADDAGALLA A, et al. Not too hot to handle: water based fluid drills high temperature wells[C]. Society of Petroleum Engineers. doi: 10.2118/196796-MS [19] PILGUN S, ARAMELEV A. Environmentally compatible drilling fluids[C]. Society of Petroleum Engineers. doi: 10.2118/166847-MS [20] AUDIBERT A , ROUSSEAU L, KIEFFER J. Novel high-pressure/high temperature fluid loss reducer for water-based formulation[C]. Society of Petroleum Engineers. [21] CESARONI R , REPETTI U. Solved problems of high-density and high-temperature drilling fluid in an environmentally sensitive area[C]. Society of Petroleum Engineers. doi: 10.2118/25701-MS [22] WILSON A. Novel drilling fluids enable record high-temperature well offshore Malaysia[C]. Society of Petroleum Engineers. doi: 10.2118/1115-0075-JP [23] PANAMARATHUPALAYAM B, MANZOLELOUA C, SEBELIN L, et al. Multifunctional high temperature water-based fluid system[C]. Society of Petroleum Engineers. doi: 10.2118/195009-MS [24] 陈作, 许国庆, 蒋漫旗. 国内外干热岩压裂技术现状及发展建议[J/OL]. 石油钻探技术: 1-12[2019-11-25]. http://kns.cnki.net/kcms/detail/11.1763.TE.20191104.1515.004.html.CHEN Zuo, XU Guoqing, JIANG Manqi. The current status and development recommendations for dry hot rock fracturing technologies at home and abroad[J/OL]. Petroleum Drilling Techniques: 1-12[2019-11-25]. http://kns.cnki.net/kcms/detail/11.1763.TE.20191104.1515.004.html. [25] 张森琦,文冬光,许天福,等. 美国干热岩"地热能前沿瞭望台研究计划"与中美典型EGS场地勘查现状对比[J]. 地学前缘,2019,26(2):321-334.ZHANG Senqi, WEN Dongguang, XU Tianfu, et al. Frontier observatory for research in geothermal energy project and comparsion of typical EGS site exploration status in China and U. S[J]. Earth Science Frontiers, 2019, 26(2):321-334. [26] 张盛生,张磊,田成成,等. 青海共和盆地干热岩赋存地质特征及开发潜力[J]. 地质力学学报,2019,25(4):501-508.ZHANG Shengsheng, ZHANG Lei, TIAN Chengcheng,et al. Occurrency geological characteristics and development potential of hot dry rocks in Qinghai Gonghe basin[J]. Journal of Geomechanics, 2019, 25(4):501-508. [27] 张盛生,张磊,蔡敬寿,等. 共和盆地恰卜恰地区干热岩资源量初步估算及评价[J]. 青海大学学报,2018,36(4):75-78,85.ZHANG Shengsheng, ZHANG Lei, CAI Jingshou, et al. Preliminary estimation and evaluation of hot dry rock resources in Qiabuqia area of Gonghe basin[J]. Journal of Qinghai University, 2018, 36(4):75-78,85. [28] 思娜,叶海超,牛新明,等. 油气钻井技术在干热岩开发中的适应性分析[J]. 石油钻探技术,2019,47(4):35-40.SI Na, YE Haichao, NIU Xinming, et al. Analysis on the adaptability of oil and gas drilling technologies in development for hot dry rocks[J]. Petroleum Drilling Techniques, 2019, 47(4):35-40. [29] 叶顺友,杨灿,王海斌,等. 海南福山凹陷花东1R井干热岩钻井关键技术[J]. 石油钻探技术,2019,47(4):10-16.YE Shunyou, YANG Can, WANG Haibin, et al. Key drilling technologies for hot dry rock in well HD-1R in the Hainan Fushan sag[J]. Petroleum Drilling Techniques, 2019, 47(4):10-16. [30] 梁文利. 干热岩钻井液技术新进展[J]. 钻井液与完井液,2018,35(4):7-13. doi: 10.3969/j.issn.1001-5620.2018.04.002LIANG Wenli. Progress on drilling fluid technology for hot dry rock drilling[J]. Drilling Fluid & Completion Fluid, 2018, 35(4):7-13. doi: 10.3969/j.issn.1001-5620.2018.04.002 [31] 许天福,胡子旭,李胜涛,等. 增强型地热系统: 国际研究进展与我国研究现状[J]. 地质学报,2018,92(9):1936-1947. doi: 10.3969/j.issn.0001-5717.2018.09.012XU Tianfu,HU Zixu,LI Shengtao,et al. Enhanced geothermal system: international progresses and research status of China[J]. Acta Geologica Sinica, 2018, 92(9):1936-1947. doi: 10.3969/j.issn.0001-5717.2018.09.012 [32] 李旭方,熊正强. 抗高温环保水基钻井液研究进展[J]. 探矿工程(岩土钻掘工程),2019,46(9):32-39.LI Xufang, XIONG Zhengqiang. Research progress on high temperature resistant and environment friendly water-based drilling fluids[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling) , 2019, 46(9):32-39. [33] 秦耀军,李晓东,赵长亮,等. 耐240℃高温钻井液在青海共和盆地高温干热岩钻探施工中的应用[J]. 地质与勘探,2019,55(5):1302-1313.QIN Yaojun, LI Xiaodong, ZHAO Changliang, et al. Application of high temperature (240℃) -resistant fluid to a HDR drilling project in the Gonghe basin,Qinghai province[J]. Geology and Exploration, 2019, 55(5):1302-1313. [34] 董海燕,单文军,李艳宁,等. 耐高温泡沫钻井液技术研究概况及研究方向探讨[J]. 地质与勘探,2014,50(5):0991-0996.DONG Haiyan, SHAN Wenjun, LI Yanning, et al. Research progress and direction of the anti-high temperature foam drilling fluid technology[J]. Geology and Exploration, 2014, 50(5):0991-0996. [35] 许洁,乌效鸣,王稳石,等. 松科2井抗超高温钻井液技术[J]. 钻井液与完井液,2018,35(2):29-34,39. doi: 10.3969/j.issn.1001-5620.2018.02.004XU Jie, WU Xiaoming, WANG Wenshi, et al. Ultra-high temperature drilling fluid technology of well Songke-2[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):29-34,39. doi: 10.3969/j.issn.1001-5620.2018.02.004 [36] 黄雪琴,孟庆昆. 液氮应用于干热岩钻探的可行性探讨[J]. 探矿工程(岩土钻掘工程),2018,45(2):22-25.HUANG Xueqin, MENG Qingkun. Feasibility study on application of liquid nitrogen in hot rock drilling[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling) , 2018, 45(2):22-25. [37] 杨莉,姚建华,罗平亚. 钻井液常见污染问题及处理方法探讨[J]. 钻井液与完井液,2012,29(2):47-50,93. doi: 10.3969/j.issn.1001-5620.2012.02.016YANG Li, YAO Jianhua, LUO Pingya. Common drilling fluid pollution problems and solutions[J]. Drilling Fluid & Completion Fluid, 2012, 29(2):47-50,93. doi: 10.3969/j.issn.1001-5620.2012.02.016 -

下载:

下载: